2-4

Step 15.

Refer to SECTION 3, as how to set control

valve for the correct time of day.

When shifting

to daylight saving time and (back), you may

wish to adjust TIME OF DAY accordingly.

NOTE:

TIME OF REGENERATION is preset for

2:00 a.m. because at this time water consumption

is generally minimal (a built-in hard water bypass

does, however, permit water to be drawn during

regeneration). Should your life style require

regular

use of water during the 2:00 to 3:00 a.m.

regeneration period, or if other water treatment

equipment is also set for 2:00 a.m. regeneration,

the TIME OF REGENERATION will need chang-

ing. Refer to Section 3,

HOW TO SET TIME

OF REGENERATION

.

Step 16. Before loading salt, using a pail or garden hose,

add enough water to the brine tank to cover the

salt grid (lower shelf on 15" x 15" x 34" brine

tank) at least one (1) inch in depth. Then add

initial salt fill to brine tank, and one (1) cup (eight

ounces) of unscented laundry bleach to the

brine well.

Step 17. Put your new water softener through a complete

regeneration to sanitize the system prior to use.

(Refer to “HOW TO MANUALLY INITIATE THE

CONTROL VALVE” for instructions on manual

regeneration. RESTORE THE FUEL SUPPLY

OR POWER TO THE WATER HEATER”.

Installation is now complete, and your water soft-

ener is now ready for service. You can expect

many years of virtually trouble free softened water.

If need arises please contact the installing

contractor for immediate attention to your par-

ticular issue.

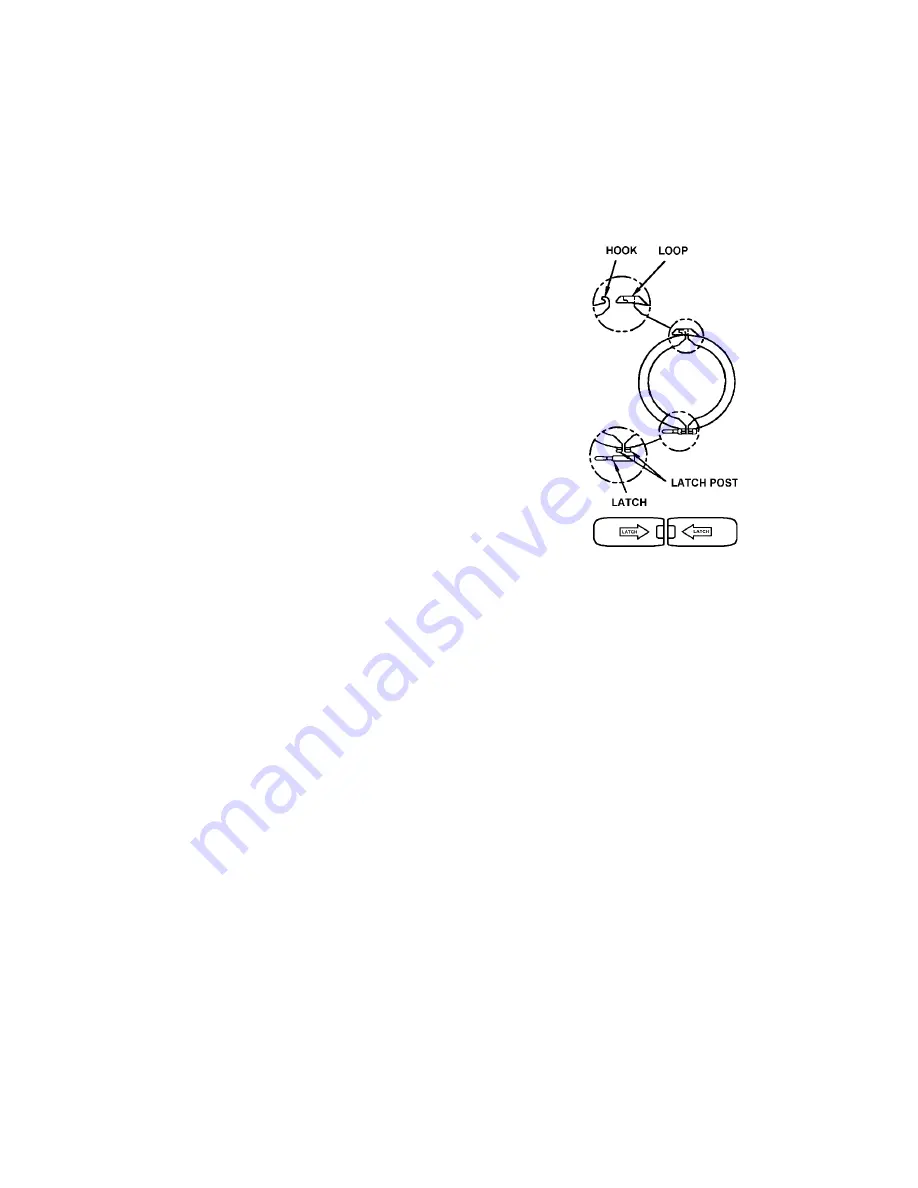

SPECIAL SERVICE INSTRUCTIONS:

Under normal circumstances removal of valve should not

be required. However, if it must be removed, it can be done

by disassembling the quick release clamp, and latch. Pres-

sure should be relieved before attempting any disassembly.

Upon reassembly, all o-rings should belubricated with

silicone grease. Reassemble clamp asshown in Figure 5.

MAKE SURE ARROWS ON LATCHSIDE OF CLAMP

ARE ALIGNED.

Figure 5. CLAMP ASSEMBLY