3M™ MicroTouch™ Controller EX Serial Reference Guide

21

3M Touch Systems, Inc. Proprietary Information – TSD-29087 Rev D

Caution:

This document assumes you are familiar with firmware commands and how to

use them. Executing some commands may alter the performance of your touch system

and render it inoperable. You should be aware of the results before executing any

firmware commands.

To optimize the performance of the touch controller and simplify the development of

custom drivers, 3M Touch Systems recommends you use the commands listed in Table 5

for current development. Using these commands ensures compatibility with all 3M™

MicroTouch™ controllers.

Note:

When you enter commands in terminal mode, precede each command with

<CTRL> A to enter the start of header.

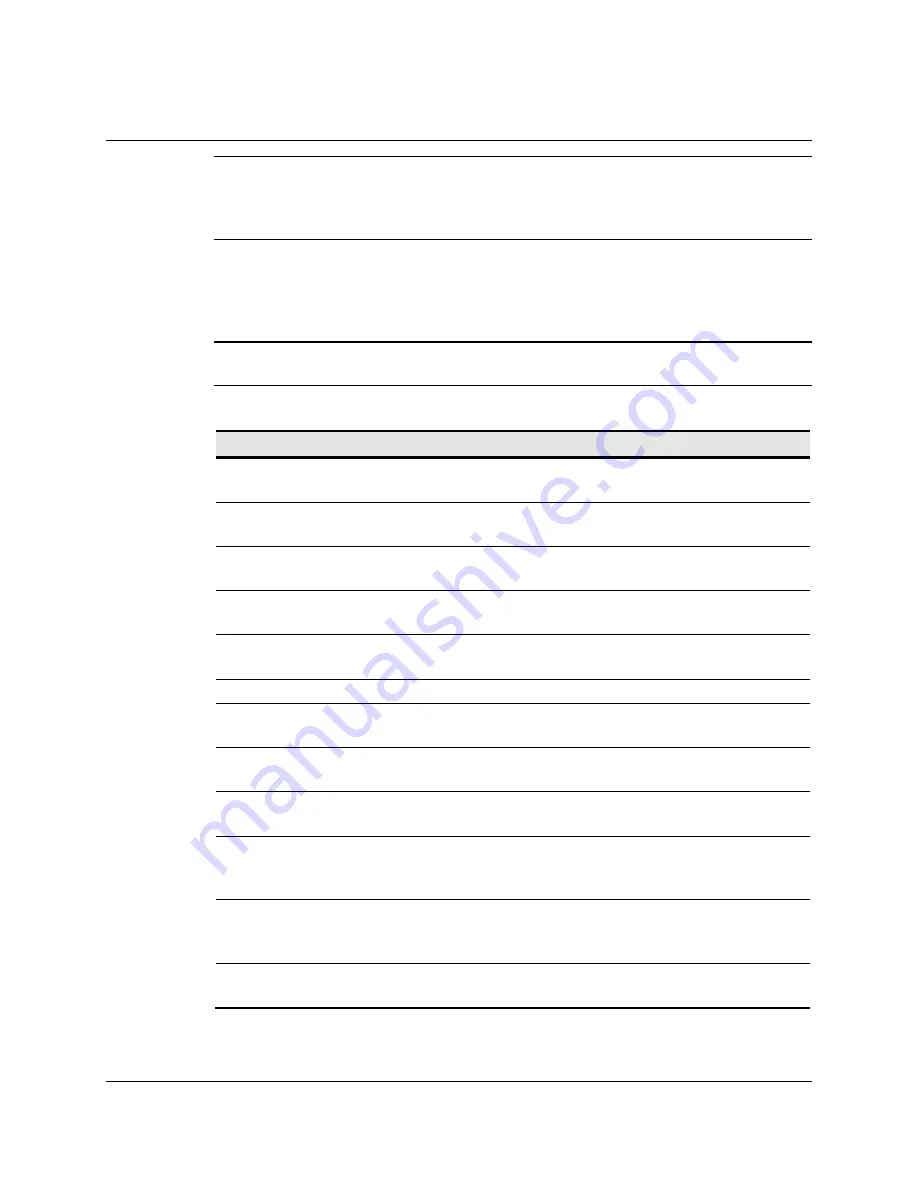

Table 5 Firmware Commands for EX Serial Controller Development

Command Code Description

Calibrate

Extended

CX

Initiates an interactive 2-point calibration.

Calibrate

Raw

CR

Collects the raw X and Y coordinates before normal scaling,

linearization, and filtering process.

Format Raw

FR

Returns the signal level (amount of touch) of each of the four

sensor corners in digital format.

Format

Tablet

FT

Outputs the X/Y touch coordinate data in a five-byte packet.

Preferred for current development.

Mode

Stream

MS

Sends a continuous stream of X/Y coordinate data when you

touch the sensor.

Name

NM

Returns a controller identifier string.

Null

Command

Z

Queries the controller and waits for a response.

Output

Identity

OI

Identifies the controller type and the firmware version.

Parameter

Set

Ppds[

b]

Lets you adjust the communication parameters (parity, data

bits, and stop bits) of the controller.

Reset

R

Initializes the hardware and the firmware, causes the

controller to stop sending data, and recalculates the

environmental conditions.

Restore

Defaults

RD

Returns the controller to the factory default operating

parameters. Note: the serial port is reset to N81 format tablet

and 2-point calibration is lost.

Unit Type

Verify

UV

Identifies the touch controller on your system.

Summary of Contents for MicroTouch EX Series

Page 8: ......