© 3M 2016

INSTRUCTION MANUAL

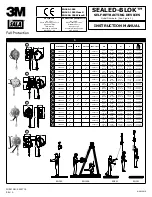

1

A

WR

W

D

L

B

EN1496

WR

W

D

L

C

EN341

WR

W

D

L

D

EN1496

EN341

WR

W

D

L

Sealed-Blok™

EN360

EN341

EN1496

FAST-Line™

WR

L

W

D

D

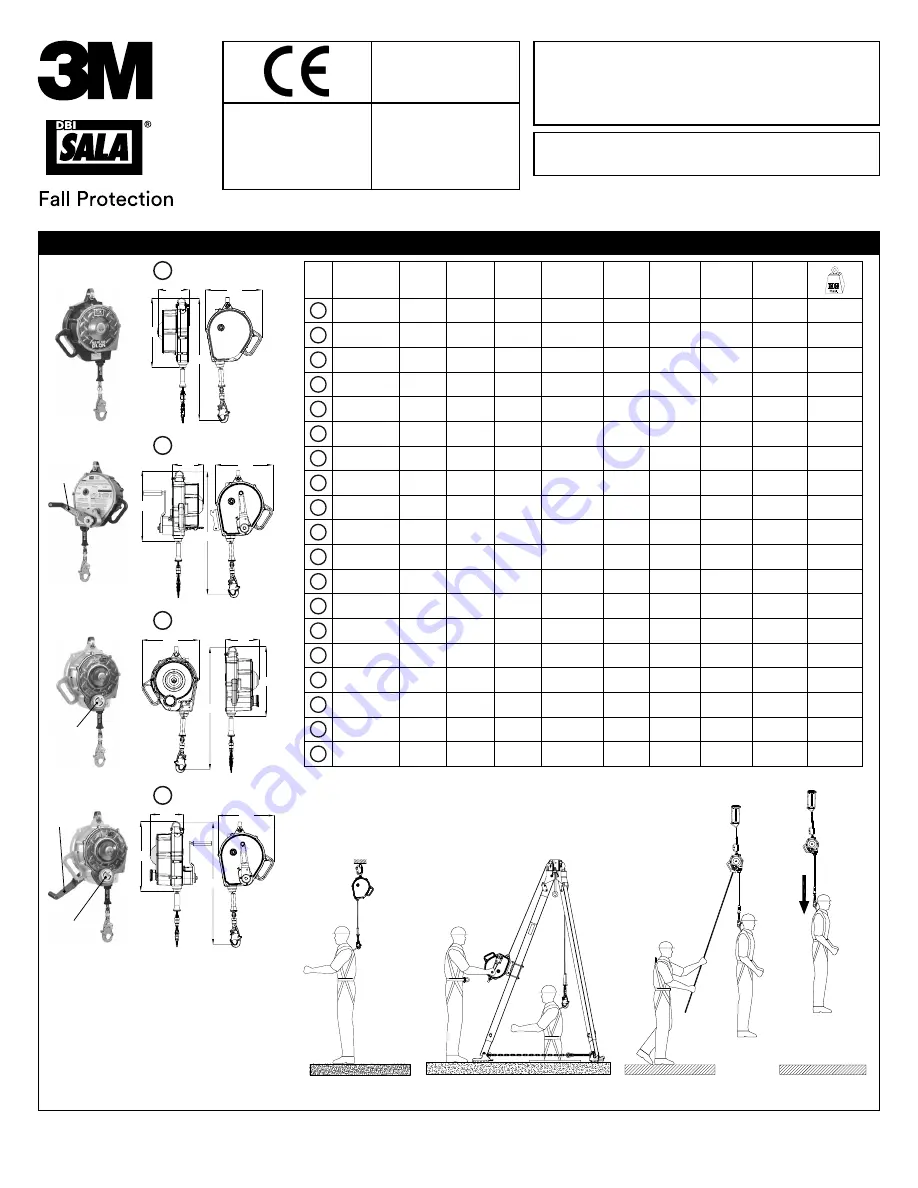

3400944

3900107

15 m

(50 ft)

34 cm

(13.3 in)

27 cm

(10.4 in)

18 cm

(6.9 in)

141 kg

(310 lbs)

A

3400950

3900105

15 m

(50 ft)

34 cm

(13.3 in)

27 cm

(10.4 in)

18 cm

(6.9 in)

141 kg

(310 lbs)

A

3400951

3900107

15 m

(50 ft)

34 cm

(13.3 in)

27 cm

(10.4 in)

18 cm

(6.9 in)

141 kg

(310 lbs)

B

3400955

3900105

15 m

(50 ft)

34 cm

(13.3 in)

27 cm

(10.4 in)

18 cm

(6.9 in)

141 kg

(310 lbs)

B

3400956

3900107

15 m

(50 ft)

34 cm

(13.3 in)

27 cm

(10.4 in)

18 cm

(6.9 in)

141 kg

(310 lbs)

C

3400961

3900107

15 m

(50 ft)

34 cm

(13.3 in)

27 cm

(10.4 in)

18 cm

(6.9 in)

141 kg

(310 lbs)

A

3400866

3900108

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

A

3400867

3900111

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

B

3400880

3900108

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

B

3400881

3900111

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

C

3400891

3900108

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

C

3400892

3900111

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

D

3400916

3900108

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

D

3400917

3900111

26 m

(85 ft)

39 cm

(15.4 in)

30 cm

(11.8 in)

18 cm

(7 in)

141 kg

(310 lbs)

A

3400971

3900112

40 m

(130 ft)

43 cm

(16.8in)

36 cm

(14 in)

20 cm

(8 in)

141 kg

(310 lbs)

A

3400972

3900113

40 m

(130 ft)

43 cm

(16.8in)

36 cm

(14 in)

20 cm

(8 in)

141 kg

(310 lbs)

B

3400986

3900113

40 m

(130 ft)

43 cm

(16.8in)

36 cm

(14 in)

20 cm

(8 in)

141 kg

(310 lbs)

A

3400656

3900168

53 m

(175 ft)

43 cm

(16.8in)

36 cm

(14 in)

31 cm

(12.3 in)

141 kg

(310 lbs)

A

3400658

3900170

53 m

(175 ft)

43 cm

(16.8in)

36 cm

(14 in)

31 cm

(12.3 in)

141 kg

(310 lbs)

EN360

EN1496

EN341

EN341

EN360: 2002

EN341: 1992 Class D

EN1496: 2006 Class B

CE Type Test

No. 0321

Satra Technology Centre

Wyndham Way

Telford Way

Kettering, Northants

NN16 8SD, UK

CE Production Quality Control

No. 0086

BSI Product Services

Kitemark Court

Davy Avenue

Knowlhill, Milton Keynes

MK5 8PP, UK

FORM NO: 5903776

REV: A

SEALED-BLOK™

SELF-RETRACTING DEVICES

Model Numbers:

(See Figure 1.)