3M™ MicroTouch™ Controller RX141 Reference Guide

31

3M Touch Systems, Inc. Proprietary Information

1 false touch allowed

±20KV Air Discharge – Class 1 per section 9 of IEC 61000-4-2

Compliant

Normal Operation – No false touches

MTBF (by MIL Std. 217F Calculation)

>400,000 Hours

3M Touch Systems Parameters

Accuracy vs. Dynamic Temperature Change

Maintains 1% Accuracy

(tested at 0

°

C to 65

°

C with a 0.5

°

C/minute temperature ramp)

Communications

Protocol

USB

Rev

1.1

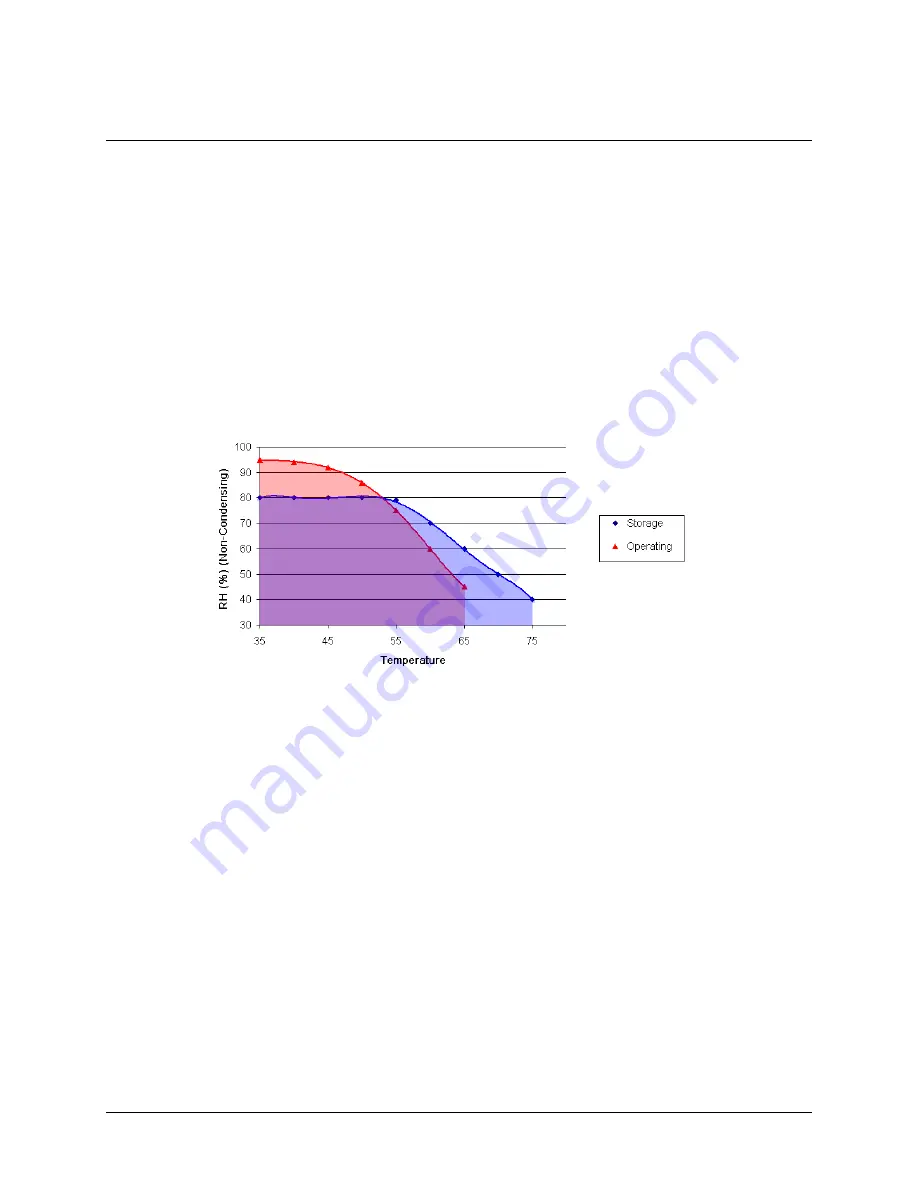

Figure 4. Storage and Operating Temperature and Humidity Conditions