To use the 3M Heat Trace Bill of Materials Tool, visit

3M.ca/HeatTrace

To use the 3M Heat Trace Bill of Materials Tool, visit

3M.ca/HeatTrace

19

Note: Pipewall sensing is required for non-metallic piping.

proper temperature. Where a piping system has tees and therefore multiple flow paths,

more than one thermostat may be required. Examples of situations where more than one

thermostat could be necessary:

• Pipes of varying diameters or insulation thicknesses

• Varying ambient conditions such as above/below ground transitions and indoor/outdoor transitions

•

Flowing versus non-flowing conditions within the interconnected piping

• Applications involving temperature-sensitive products

While these four steps provide the considerations required to plan the materials list and/or specify a TTS™ Self-

Regulating Heating Cable Self-Regulating Heat Tracing System, some type of control will typically be needed. The type

of control and level of sophistication needed will depend entirely on the application of the piping being heat-traced.

Self-regulating heating cables can, under some design conditions, be operated without the

use of any temperature control. However, some method of control is generally used and the

two most common methods are

ambient sensing

and

pipewall sensing

. Each method has its

own benefits, and various options are available within each method.

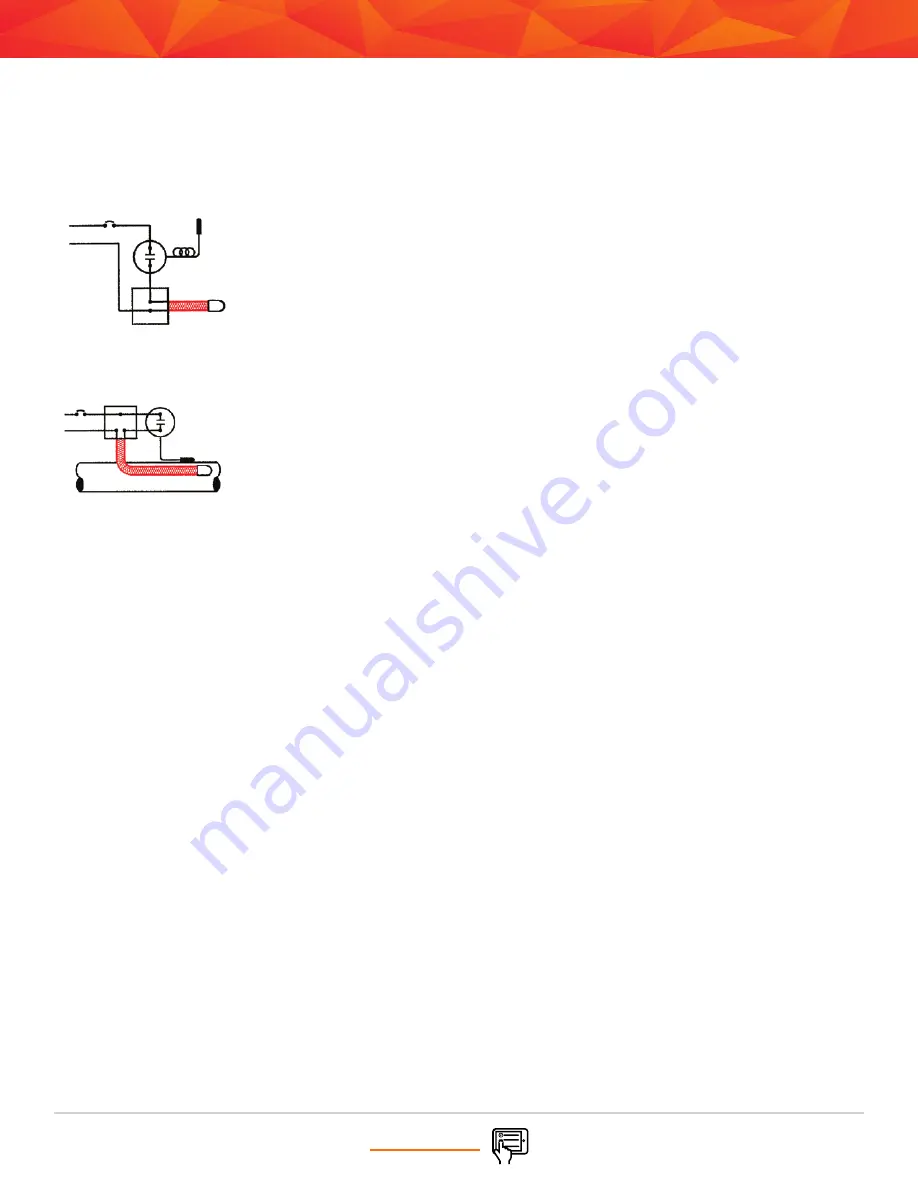

Ambient Sensing:

An adjustable thermostat, designed for mounting in an exposed

environment, senses the outside air temperature. When this temperature falls below the

setpoint, a set of contacts close and energize the heating cable(s).

Should the electrical load of the heating circuit exceed the rating of the thermostat switch,

a mechanical contractor can be used. An entire power distribution panel, feeding dozens

of heat tracing circuits, can be energized through an ambient sensing thermostat. The

primary application for ambient sensing control of electric heat tracing is freeze protection

(winterization) of water and water-based solutions.

A benefit of ambient sensing control

for freeze protection is that pipes of varying diameters and insulation thicknesses can be

controlled as a single circuit.

By controlling heat tracing with ambient sensing control, the status (flowing or non-flowing)

of the heated pipe needs no consideration.

Pipewall Sensing:

While a self-regulating cable adjusts TTS™ Self-Regulating Heating Cable

heat output to accommodate the surrounding conditions,

the most energy-efficient method

for controlling heat tracing is a pipewall-sensing thermostat.

This is because a flowing pipe will typically not need any additional heat to keep it at the

Thermostatic Control

Summary of Contents for TTS-5-1-OJ

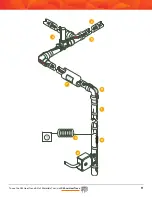

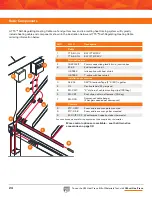

Page 7: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 7 2 2 2 2 2 3 3 3 3...

Page 8: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 8 Pipe Freeze Protection...

Page 11: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 11 4 5 6 7 9 1 8 3 2...