To use the 3M Heat Trace Bill of Materials Tool, visit

3M.ca/HeatTrace

34

Information from IEEE Standard 515.1-1995

and ASHRAE)

to simplify the selection process for determining the level

of protection required. An additional table can be found in

the Cable Spacing Selection Guide on page 39.

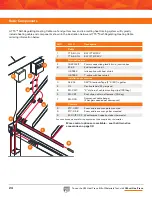

Creating a Materials List

The following five steps outline the selection process for a snow melting system using KSR™ Self-Regulating

Heating Cable.

Following each design step is an example that illustrates the process of evaluating, planning and specifying a snow

melting system.

While the example shown is small, the process would be the same regardless of the area to be protected. The design

examples include flat surfaces, stairs, a ramp, expansion joints in the concrete, and the need to bring power from a

specific location.

Determining the area that will require heat tracing is based somewhat on the traffic expected during snow and ice

accumulation periods, as well as the layout of the area and TTS™ Self-Regulating Heating Cables location relevant to

prevailing winds and susceptibility to drifting.

Then you must identify the existence of electric snow and ice melting heat tracing cable in the concrete curbs,

walkways, and paving portions of the project specification. In addition, the project drawings (both electrical and site

work) should include reference to the existence of electric heat tracing.

For example, the public/employee entrance to a facility is exposed to weather with only the area directly in front of the

entry doors covered by a roof. The building is adjacent to the concrete on two sides with the accessibility ramp (which

has a retaining wall) located on the third side. Snow removal can only be accomplished at the curb and parking area, a

choice found undesirable for various reasons.

To maintain a clear entrance, the landing, stairs, ramp and approach area will require snow melting. The area in front

of the doors will be heat traced to also prevent accumulation from drifting and tracking.

Step 1: Identify area requiring snow and ice melting.

Step 2: Determine level of protection.

Phone/Cable

Room

Landing

Approach

Partial Plan at Entry

Stairs

Curb

Ramp

Up

Up

Building Entry

Figure 3.1.1

Regardless of geographical location or size of area to be protected, the heating requirements for snow melting are

affected by four primary factors:

• Rate of snowfall

• Ambient temperature

Establishing the level of protection required for a facility

requires an understanding of the type of service the area

will encounter and under what type of weather conditions

the snow and ice melting system must perform.1 3M

developed

Table

3.2.1

KSR™ Self-Regulating Heating Cable

spacing (using information from IEEE Standard 515.1-1995

and ASHRAE) to simplify determining and selecting the level

of protection required. An additional table can be found in

the Cable Spacing Selection Guide on page 37.

• Wind velocity

• Humidity

To create your materials list online, visit 3M.ca/HeatTrace.

Summary of Contents for TTS-5-1-OJ

Page 7: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 7 2 2 2 2 2 3 3 3 3...

Page 8: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 8 Pipe Freeze Protection...

Page 11: ...To use the 3M Heat Trace Bill of Materials Tool visit 3M ca HeatTrace 11 4 5 6 7 9 1 8 3 2...