12

13

ENGLISH

ENGLISH

ENTERING AND EXITING THE CONTAMINATED AREA

Prior to entering the contaminated area, complete the inspection procedures listed in this

User

Instructions

.

1. Turn the motor/blower on.

2. Check airfl ow and alarms.

Note:

High environmental noise levels or use of hearing protection may

interfere with the user hearing the audible alarms. User may need to check for the visual alarms

more frequently in high noise environments.

3. Don the TR-300 assembly and headgear. Enter the work area.

4. Leave the contaminated area immediately if any of the following conditions occur:

a. Any part of the system becomes damaged.

b. Airfl ow into the respirator decreases or stops.

c. The low airfl ow or low battery alarms trigger. In the event only an audible or only a visual

alarm triggers, the user should still immediately leave the contaminated area.

d. Breathing becomes diffi cult.

e. You feel dizzy or your vision is impaired.

f. You taste or smell contaminants.

g. Your face, eyes, nose or mouth become(s) irritated.

h. You suspect that the concentration of contaminants may have reached levels at which this

respirator may no longer provide adequate protection.

5. Do not remove the respirator or reach your hand into the headgear in areas where the air is

contaminated.

6. Follow your specifi c exiting and decontamination procedures for turning off the motor/blower and

removing the respirator system.

CLEANING AND STORAGE

WARNING

Dispose of lithium ion battery packs according to local environmental regulations. Do not crush,

disassemble, dispose of in standard waste bins, in a fi re or send for incineration.

Failure to

properly dispose of battery packs may lead to environmental contamination, fi re or

explosion.

The TR-300 assembly should be cleaned and inspected after each use and prior to storage.

Cleaning

Detach the battery pack, breathing tube and headgear from the motor/blower. Inspect all parts for

damage or other signs of excessive wear. Replace all damaged parts prior to storage or next use.

1. Motor/blower. Clean the outer surfaces of the 3M™ TR-300 PAPR Assembly and battery pack

with a soft cloth dampened in a solution of water and mild, pH neutral detergent. Do not immerse

the motor/blower or battery pack in water. Do not use solvents or abrasive cleaners. Do not

attempt to clean the interior of the motor/blower with compressed air or vacuum. Ensure the

electrical contacts of the motor/blower and battery pack are dry.

2. Breathing tube. Clean the connection sites on the breathing tube with the water and detergent

solution. The breathing tube can be immersed in water for cleaning. The inside of the tube must

be completely dried prior to use or storage. Air dry, or dry by connecting to the motor/blower unit

and use it to force air through the tube until dry. Optional breathing tube covers can also be used

to facilitate cleaning.

4. HE

fi

lter.

o

Inspect fi lter and seal for dirt, tears, cuts, distortion or indentations. If needed, the seal can be

cleaned with fresh water - do not use soaps or solvents. Do not immerse or attempt to clean

the HE fi lter itself. Replace HE fi lter if any damage is noted or suspected.

o

Ensure the HE fi lter is properly installed in the PAPR unit and that the cover latch is secure per

this

User Instructions

. The HE fi lter label must be visible in the cover window (See Fig. 11). The

HE fi lter should not be stored long-term in the motor/blower unit

o

If sparks or other hot particles are present, the TR-362 or 362-SG spark arrestor must be in

place in front of the HE fi lter.

Failure to use the spark arrestor may allow the fi lter to be

damaged with subsequent user exposure to contaminated air.

5. Airfl

ow

check:

o

Ensure ball in the TR-970 moves freely in its tube and the seal at the bottom end of the tube is

in place. Rinsing with clean water may help free a stuck ball. Allow tube and ball to dry prior to

using.

o

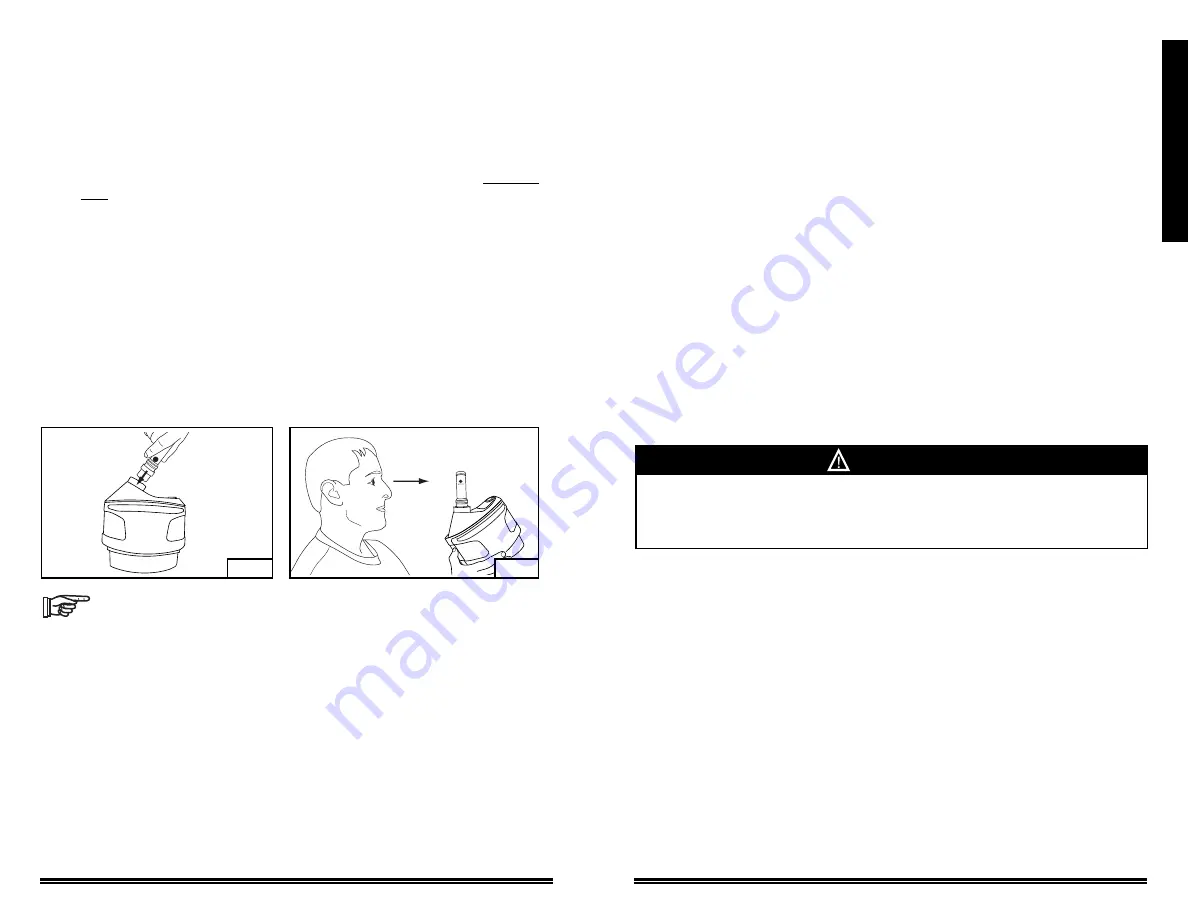

Insert the TR-970 air fl ow indicator into the outlet on the TR-300 motor/blower unit. If the

breathing tube is in place it must be removed to allow the air fl ow indictor to be inserted

(Fig. 13).

o

Turn the motor/blower unit on by pushing and holding the power button. Run the TR-300 for

1 minute to allow the air fl ow to stabilize.

o

With the airfl ow indicator in a vertical position, ensure that the bottom of the fl oating ball rests

at, or above, the minimum fl ow mark (Fig. 14). Airfl ow indicator must be in the vertical position

for an accurate reading.

Fig. 13

Fig. 14

Note:

If the airfl ow indicator ball fails to rise at or above the minimum fl ow level, do not

use the unit. Refer to the TR-300 trouble-shooting guidance document or contact 3M

Technical Service.

6. Check the low airfl ow alarm by simulating a low airfl ow condition. With the motor/blower on:

o

Remove the air fl ow indicator and tightly cover the outlet of the motor/blower with the palm

of your hand. The motor should automatically speed up, attempting to compensate for the low

airfl ow condition.

o

Continue to press your palm tightly against the end of the outlet, making a tight seal. After

approximately 30 seconds, the unit will sound an audible alarm and the red fan shape LED on

the top of the motor/blower unit will fl ash (Fig 12-3).

o

Remove your hand from the end of the breathing tube; the audible alarm and the fl ashing red

LED should both stop when the motor returns to a slower speed.

netzerotools.com

netzerotools.com