13

Torque spanners

Chain

To ensure that it can work effectively, the chain

has to be cleaned and greased regularly (see

page 25). Dirt can be removed when washing

the rest of the bicycle. Otherwise you can clean

the chain by rubbing it with an oily clot. When the

chain is clean, it should be greased at the joints

with suitable lubricant. After being left to soak,

the excess lubricant should then be removed.

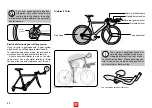

To ensure that the chain and gears

can work safely, the chain has to

have a certain level of tension. De

-

railleur gear systems tense the chain auto-

matically. In the case of hub gears which were

installed without a chain tensioner, chains

which are too loose have to be tightened. Oth-

erwise they can come off and lead to a fall.

In the case of bicycles with adjust-

able dropouts, the mounting screws

of the axle housing should be loos-

ened and tightened, and not the axle nuts. If

the bottom bracket shell contains an eccentric

Chain tension

bush, please tighten the chain according to

the instructions provided by the correspond-

ing manufacturer.

Please ensure that axle nuts and

quick releases are correctly at-

tached!

1

2

3

10-15 mm

* see page 26

If your bicycle is equipped with a

belt drive, please read the attached

component manufacturer’s operating

instructions before first use.

Belt drive

Dirt and permanent strain wear

the chain. The chain should be re-

placed as soon as it can be signifi-

cantly lifted (approx. 5 mm) from the front

chain ring. Many modern chains for derail-

leur gear systems no longer have chain

connectors. You therefore require special

-

ist tools to open/change/close them. This

work should be carried out by a specialist

retailer.

Other chains are supplied/assembled with

chain connectors. In some cases, these can

be opened without the need for tools. These

chain connectors can also be used to repair

a damaged chain on a ride, if they have the

correct width for the drive train.