•

These clamps must be regularly checked to ensure that the correct tension is applied to the

catch plate; if there is too much tension then the catch plate can become over stressed and

through time will become bent open; if there is too little tension then the clamp will be

loose and there will be the risk that it does not maintain a grip on the catch plate. The

excessive compression on the silicone sponge will also cause deformation in this seal and

may allow moisture and heat to more easily enter the inner workings of the electronics.

•

The tension on the clamp can be adjusted to ensure a reasonable grip on the catch plate.

Turning the screw with the terminal screwdriver will adjust the tension. Too much tension

will cause the catch plate to bend when the clamp is closed. If this occurs then the clamp

should be loosened. Too little tension and the claw will rattle on the catch plate. If this

occurs then the clamp should be tightened. The tension should be such that the clamp can

be closed easily between finger and thumb without having to strike the clamp or use excess

force.

•

Clockwise adjustment: tightens clamp

•

Anti-clockwise adjustment: loosens clamp

Toggle Clamp Tension Adjustment

.

Toggle Clamp Maintenance

38

Summary of Contents for K-Paq Junior

Page 1: ...Owner s Guide Junior...

Page 2: ......

Page 11: ...Flying Lead Aerial 4 The finished installation position of the flying lead aerial 11...

Page 46: ...DASHBOARD SCREEN 1 46...

Page 48: ...GRAPH SCREEN 1 48...

Page 50: ...DATA SCREEN 1 50...

Page 52: ...ANATOMY OF A ROTOMOLDING CYCLE 52...

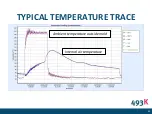

Page 53: ...TYPICAL TEMPERATURE TRACE Ambient temperature outside mold Internal air temperature 53...