64

Calibration Certificate for K-PAQ Rotational Moulding Temperature

Measurement System

Valid On:

Customer:

K-PAQ Electronics Serial Numbers

have been calibrated to an accuracy of + / - 4º C.

Signature

Date:

Position

It is recommended that the equipment is calibrated annually to ensure satisfactory operation.

Please note: Individual thermocouples should undergo similar calibration tests in order to adjust overall

system calibration.

Summary of Contents for K-Paq Junior

Page 1: ...Owner s Guide Junior...

Page 2: ......

Page 11: ...Flying Lead Aerial 4 The finished installation position of the flying lead aerial 11...

Page 46: ...DASHBOARD SCREEN 1 46...

Page 48: ...GRAPH SCREEN 1 48...

Page 50: ...DATA SCREEN 1 50...

Page 52: ...ANATOMY OF A ROTOMOLDING CYCLE 52...

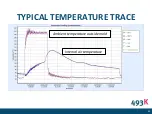

Page 53: ...TYPICAL TEMPERATURE TRACE Ambient temperature outside mold Internal air temperature 53...