PAGE 22

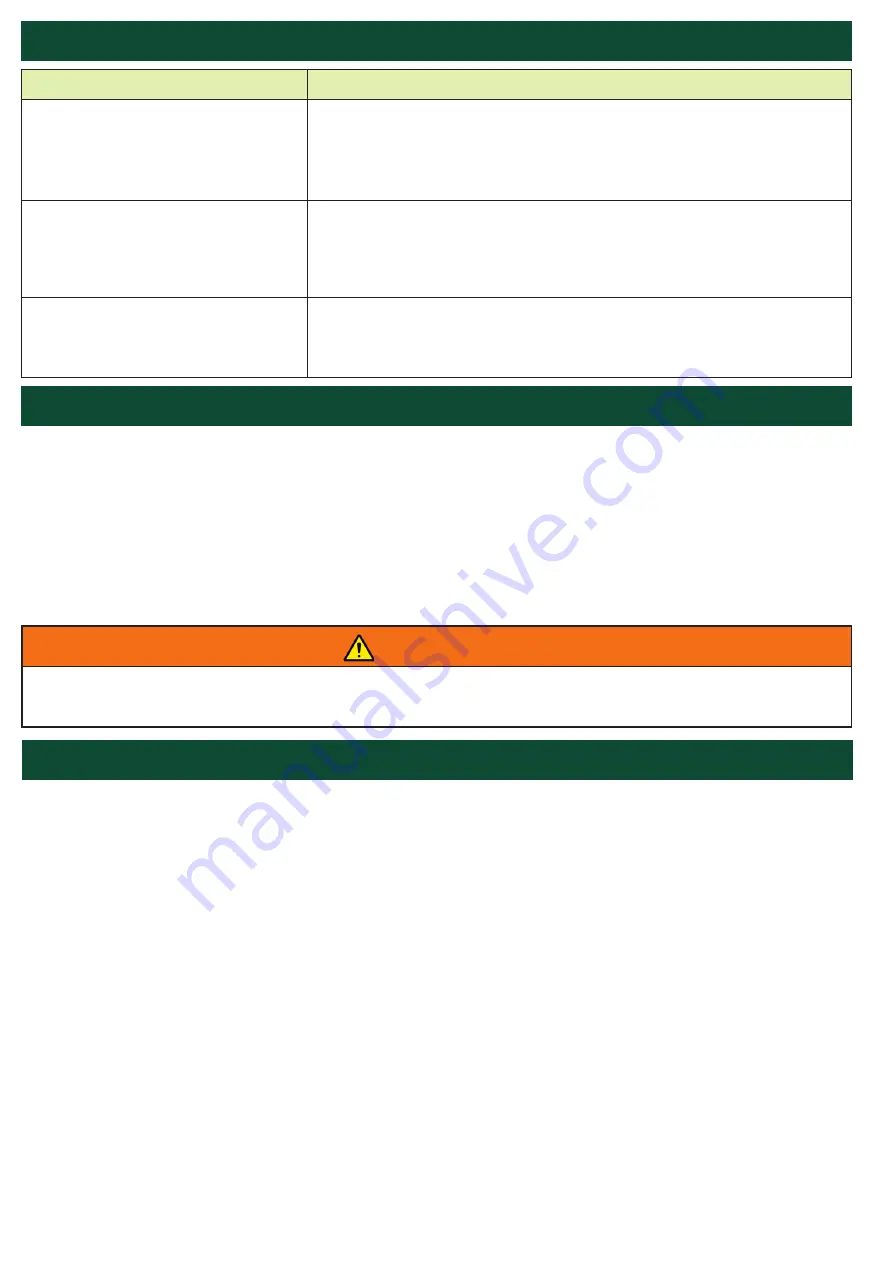

13. TROUBLESHOOTING GUIDE

CONDITION

SOLUTION

Power LED is Off

1. Check that power is applied to the unit on appropriate

terminals (21 - 24).

2. Check that the mains input fuse F6 is not damaged.

3. Check that the internal circuitry fuse F5 is not damaged.

No power to the sensors

1.

Check that the field power fuses (F1 - F4) are not damaged.

2.

Check the field wiring to make sure +24 VDC supply is

delivered to the sensors.

3. Replace faulty fuses and sensors as necessary.

4-20 mA (current loop) sensor in

short circuit

1. Check if the sensor is powered correctly (+24 VDC).

2. Check that the sensor is wired correctly.

3. If needed, replace the faulty sensor.

WARNING

If the system does not immediately shutdown as expected or alarm as required, then remove the

machine from service until the problem has been diagnosed and corrected.

14. TESTING AND MAINTENANCE

Below is the procedure that the end user must adhere to in order to maintain the system in a safe state.

1. Inspect that all the cabling is in good state and that all the electrical connections, including the

terminal blocks in the junction boxes are secure and in good order.

2. Make sure there is no water damage to the inside of the node or any junction boxes used.

3.

Verify that the configuration switches of the IE-NODE are set as intended.

4.

Verify that the LED marked (HB) is flashing at a regular rate.

5. Test sensor settings, check for PLC communication loss, etc. to ensure the controller is behaving

as expected.

15. WARNINGS PRESENT ON PRODUCT

ClassII Div2 - ETH-NODE2V46CAI

Remove Power Before Opening Cover – Do Not Apply Power When Cover Is Open

Couper L’Alimentation Avant L’Ouverture Du Boitier – Ne Pas Alimenter Si Le Boitier Est Ouvert

Warning Static Hazard Only To Be Cleaned With Damp Cloth

Risque D’Électricité Statique – Seulement À Nettoyer Avec Un Chiffon Humide

ClassII Div1 - ETH-NODE2V4CAI

WARNING – EXPLOSION HAZARD – Do not connect or disconnect while circuit is live unless area is

known to be non-hazardous

AVERTISSEMENT - RISQUE D’EXPLOSION – Ne pas debrancher tant que le circuit est sous tension,

a moins qu’il ne s’agisse d’un emplacement non dangereux

POTENTIAL ELECTROSTATIC CHARGING HAZARD –CLEAN ONLY WITH A DAMP CLOTH

RISQUE DE CHARGE ÉLECTROSTATIQUE POTENTIEL - NETTOYAGE AVEC UN CHIFFON

HUMIDE SEULEMENT

DO NOT OPEN WHEN ENERGIZED

NE PAS OUVRIR LORSQU’IL EST ÉNERGISÉ

Manufactured by Don Electronics Limited, Westfield Industrial Estate, Kirk Lane, Yeadon, Leeds, LS19 7LX, United Kingdom

Summary of Contents for IE-NODE 2

Page 23: ...PAGE 23 END USER NOTES...

Page 24: ...END USER NOTES PAGE 24...

Page 25: ...END USER NOTES PAGE 25...

Page 26: ...PAGE 26 END USER NOTES...