November 2022

6022221B - Direct Drive HVLS Fan UM

33

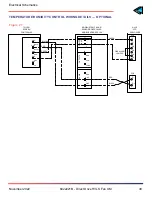

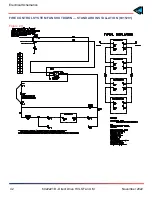

Electrical Schematics

ELECTRICAL SCHEMATICS

Before doing any electrical work, make certain the power is disconnected and properly locked

out and tagged out.

Failure to do so may result in death or serious injury.

All electrical troubleshooting and repair must be done by a qualified technician and meet all

applicable codes.

Do not route control wiring for any other device through this control box. Ensure the voltage and

phase of the incoming power agrees with the label on the top of the VFD box and fan.

Be certain the power is off when wiring to the control box. Failure to do so may result in electrical

shock, death, or serious injury.

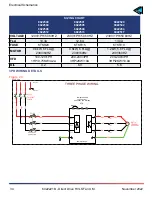

1PH WIRING DETAILS

Figure 22

2

1

FU116

600V/16A

DISCONNECT

DS103

1

2

3

4

5

6

MOT107

SEE CHART

1750RPM

HP

.

.

BLK 12AWG

RED

.

.

BLK

.

.

.

.

WHT 12AWG

WHT

.

.

1061

1071

4

1071

3

RED

.

.

WHT

.

.

GRN

.

.

R/L1

S/L2

T/L3

P1

P/+

PR

N/-

U

V

W

JUMPER

VARIABLE SPEED

FAN CONTROL

SEE CHART FOR RATINGS

POWER CIRCUIT

VFD

BLK

.

.

BLK 12AWG

.

.

WHT 12 AWG

.

.

SINGLE PHASE WIRING

1063

1073

1083

NOTE 1

NOTE 2

1031

1032

U

TS1

V

TS1

W

TS1

L1

L2/N

NOTE:

Terminals will accept stranded wire only

TOC