9

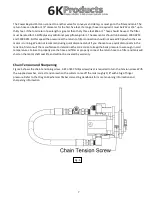

Bar Oil Pump Adjustments

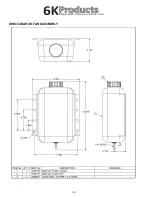

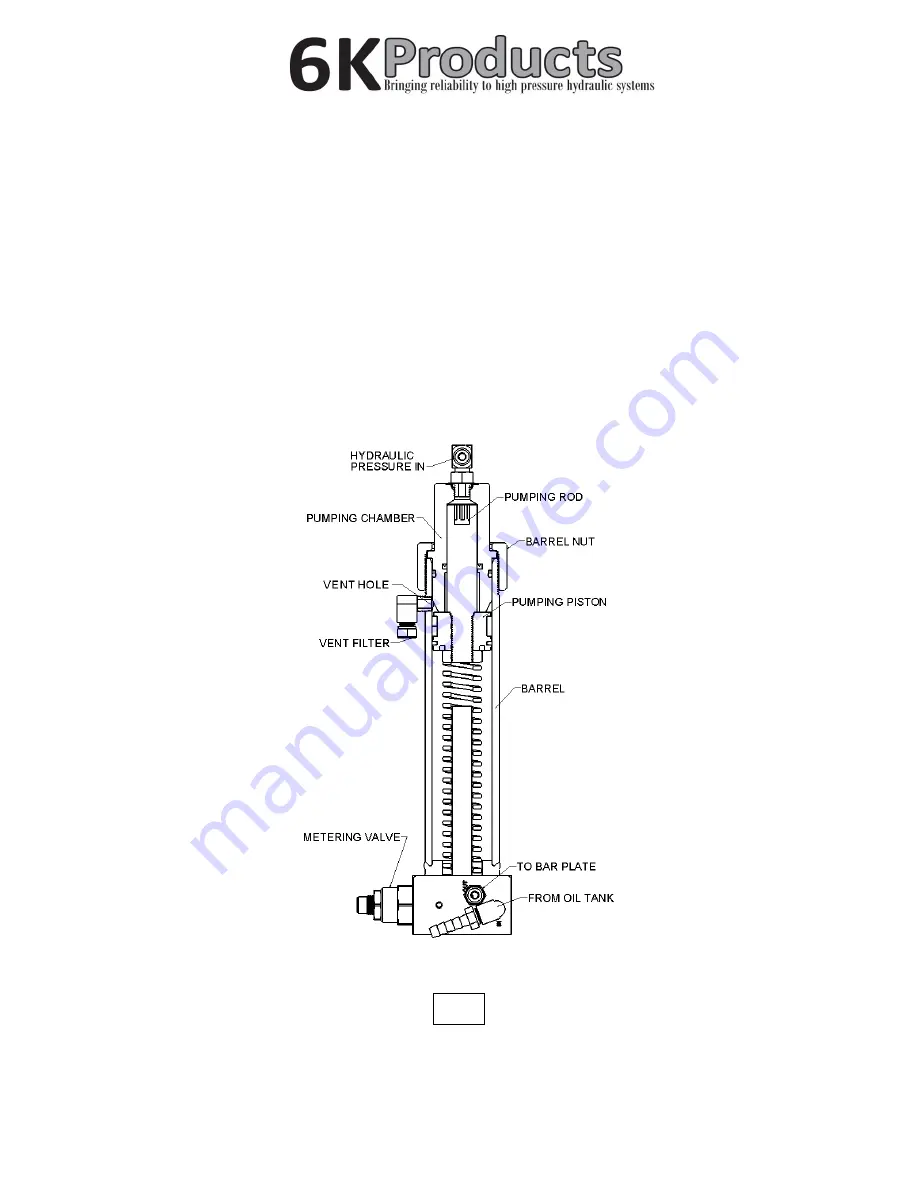

The DH0144 bar oil pump (Fig. 7) is a single acting pump that can pump up to 32 cc, or 1.08 oz., of bar oil per cycle,

enough for about 30 seconds of cutting. There is a hose connected to the selector valve manifold (Fig. 4, P4 page 6)

that connects to the fitting (Fig. 7, hydraulic pressure in) on the bar oil pump. When a cut is started flow and

pressure from the manifold pushes on the pumping rod and piston to force a metered amount of oil to the bar. Very

little rotational adjustment is needed for the metering valve in Figure 7. Turning it clockwise reduces the speed oil is

pumped and turning it counterclockwise increases the speed the oil comes out. If you run the tank out of oil you

may need to prime the pump. To prime the pump remove the barrel nut and pull out the pumping chamber,

pumping piston, and pumping rod. Fill the barrel with bar oil up to the vent hole. Reinstall the pumping rod

assembly into the pumping chamber with care to not damage the rod seal. Reinstall the pumping chamber and

pumping rod assembly into the barrel, with care to not damage the piston or the O-ring, and retighten the barrel

nut. To reduce the chance of seal damage make sure the seals are oiled and wiggle in a circular motion as you push

the parts together.

Fig. 7

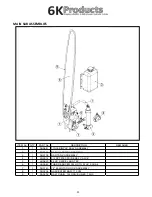

Summary of Contents for DH0626

Page 12: ...12 DH0641 SIMPLE SAW ASSEMBLY...