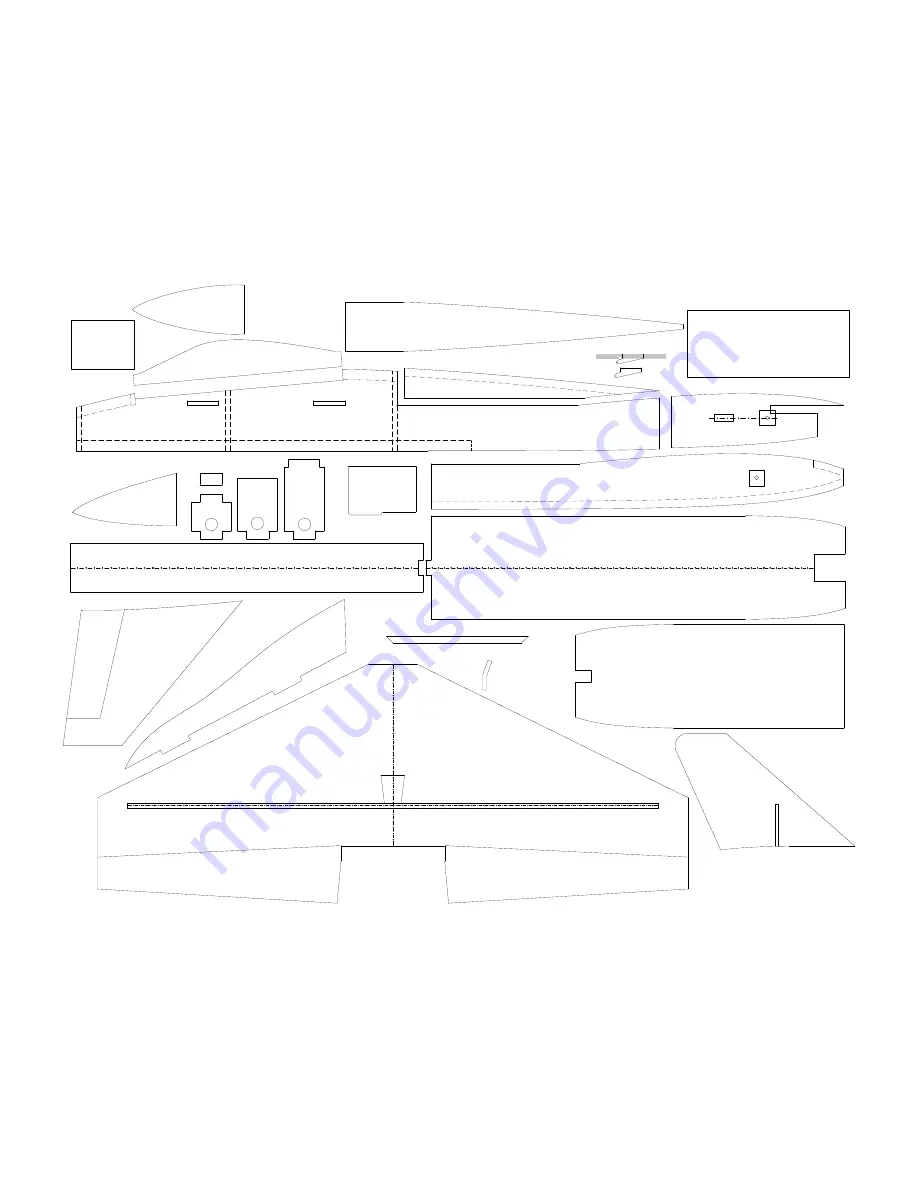

Canopy

(make 10 with and

laminate together)

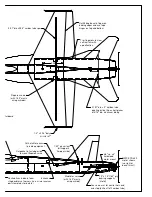

F-2

F-1

F-4

F-3

Wing (make 1)

Top fwd fuselage

(trim to fit)

Turtledeck sides (make 2)

Mounting hole for elevator servo

(cut to fit selected servo very tightly)

.75" x .75" 1/64" ply

doublers each side

(drill 3/16" hole for pivot

bearing tubes)

Motor Mount

(make 2 and laminate together)

Bulkhead F-3

(make 1)

Bulkhead F-4

(make 1)

Nosecone

(make 10 and

laminate together)

Aft Fuselage Top

(make 1)

(note this piece is slightly oversized

in length to allow trimming to exact fit)

Horizontal stabilizer

(make 2)

C

ut

fo

r s

ta

bi

la

to

r p

iv

ot

3/8" foam strip

3/8" foam

strip

Aft Fuselage Sides

(make 2)

.75" x .75" 1/64" ply

doublers on inboard side

(drill 3/16" hole for pivot

bearing tubes)

Nosecone top view template

(trace outline on top of nosecone

to assist in carving it to shape)

Cut notch to fit

motor used

1/4" x 5/16" balsa wingtip missle rails

Cut slot to fit wing spar

3/8" foam strip (2 layers)

3/8" fo

am str

ip (2 la

yers)

3/8" foam strip

Cut slot for strake

Cut slot for strake

Fwd Fuselage Sides (make 2)

Vertical tail supports

(make 4 from 1/32" plywood)

Flaperon control horns

(make 2 from 1/32" plywood)

Designed by Steve Shumate

All parts made from 6 mm Depron

unless otherwise specified

Copyright © 2004 All Rights Reserved

3/8" foam strip

C

ut

ou

t a

cc

es

s

ho

le

fo

r r

ad

io

Bulkhead F-2

(make 1)

Bulkhead F-1

(make 1)

Inlet Diverter

(make 2 from

3mm Depron or

1/8" light balsa)

Cut notch to fit

motor used

Aft Fuselage Bottom

(make 1)

Fwd Fuselage Bottom (make 1)

Stra

ke

(ma

ke

2)

Vertical tail

(make 2)

Aft Fuselage Turtledeck Top

(make 1)