5

Assembly

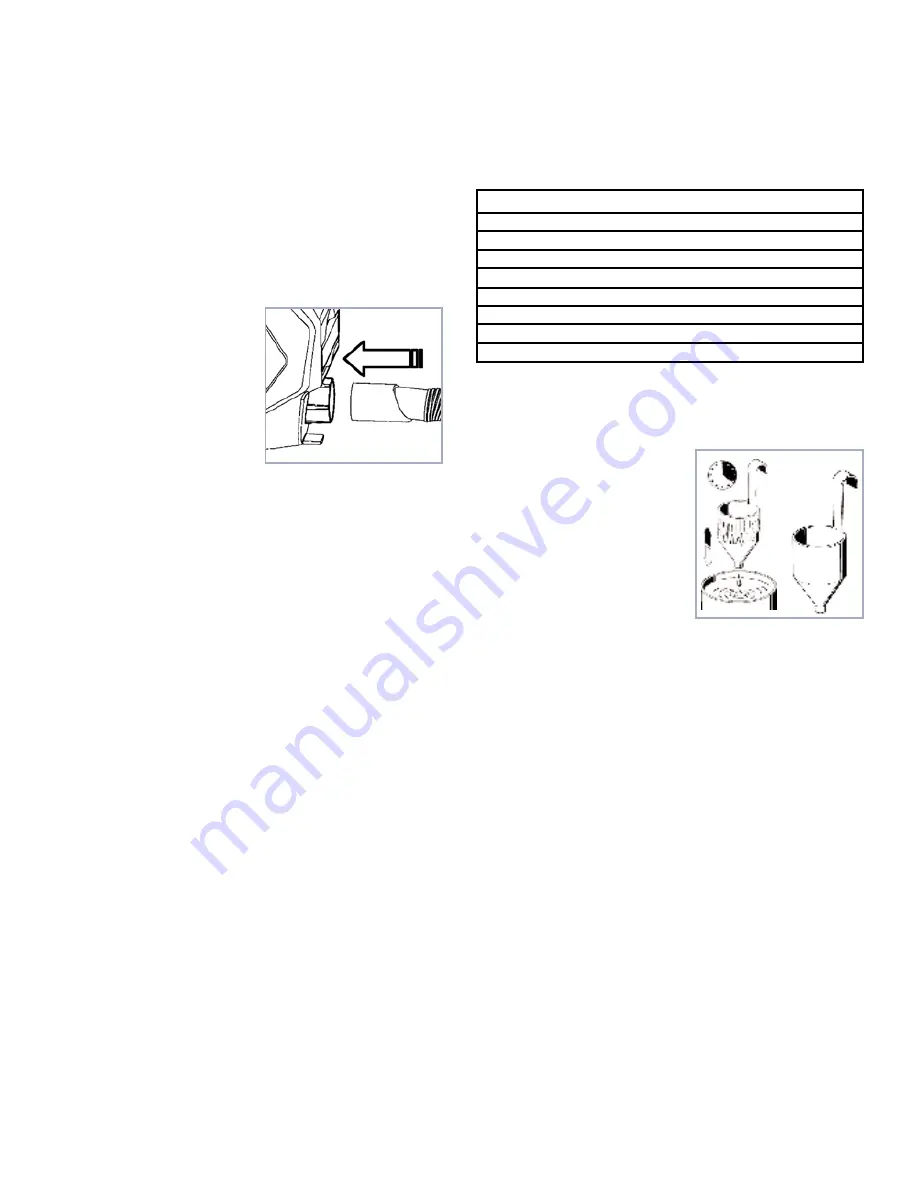

Fitting the Flexible Hose

1. The hose (15) needs to be connected to both the ports on the

paint sprayer and the spray gun (3).

Note

: This hose has identical fittings on both ends so can be

connected using either end.

2. Insert one end of the hose (15)

into the paint sprayer outlet port

(17) by pushing it into the port

until firm. (Ref Fig A)

3. Repeat this step connecting the

other end of the hose (15) to

the spray gun inlet port (16).

What substances can this

Paint Sprayer

be used with?

The following substances are suitable for use with this

Paint Sprayer:

• Water- and solvent-based paints, finishes, primers,

2-component paints, clear finishes, automotive finishes,

staining sealers and wood sealer-preservatives.

DO NOT

use the following:

• Dispersion and latex paints

• Materials containing strong abrasives,

• Glazes with coarse particles,

• Strippers and caustic solutions,

• Silicate paints.

• Wall paints (emulsions)

• Lyes and acid containing coating materials.

Note:

The use of these spray materials can lead to increased

wear or corrosion damage in the nozzle of the sprayer, which is

not covered by warranty.

Preparation of Spray Material

Most paints will require dilution before using with your Paint

Sprayer. Refer to the guidelines in the viscosity table below for

the recommended required dilution. The correct dilution can be

achieved by using the viscosity test cup supplied with your paint

sprayer. (Note: Viscosity = consistency of the paint).

Measuring the Viscosity

To measure the viscosity of the spray material follow these

instructions (refer Fig B):

1. Dip the viscosity test cup

completely into the spray material

to be used.

2. Hold the test cup up and

measure the time (in seconds)

until the liquid empties out of the

viscosity cup.

3. Compare the measured “runout

time” with the Viscosity Table to

establish the required viscosity

Preparing for Operation

Ensure you check and follow the below recommended steps

before using your Paint Sprayer

1. Before connecting your paint sprayer to the mains supply,

ensure that the supply voltage is identical with the value

given on the rating label (on the side of the Paint sprayer).

Note:

To reduce the risk of electric shock, the manufacturer

recommends the use of a residual current of 30mA or less at

all times.

2. Dilute the spray material according to the viscosity table.

3. Place the paint pot on a sheet of paper and fill it with the

prepared spray material.

NOTE:

It is strongly recommended to fill the paint pot through a

fine strainer/gauze to filter the paint.

WARNING:

Do not operate the spray gun without spray material

in the paint pot.

4. Carefully secure the filled paint pot to the lid on the spray gun

by turning it in a clockwise direction until secure.

Fig. A

Fig. B

Viscosity Table

Spray material Run out Time in Seconds

Thinner-soluble primers

25-40

Thinner-soluble varnishes 15-40

Water-soluble primers 25-40

Water-soluble varnishes 20-35

Wood preservatives, strippers, oils undiluted

Disinfectants, plant protectants undiluted

Automobile spray paint 20-35