10

Hints for use

Note.

When drilling into masonry, the drilling rate is fast and

burnout of the tip will occur if the drill bit is not constantly

cleared.

• Use only correctly sharpened drill bits, which are suitable

for the material being drilled.

• To drill hard materials, apply enough firm pressure only to

safely control the powertool. Excessive pressure does not

improve performance and places unnecessary pressure

on the tool and its bit.

• When driving screws, always use a pilot hole and set the

speed dial to low.

• It is always wiser to test the screw driving on a scrap

piece of the same material you are using.

• Larger diameter holes in hard wood, steel and concrete

have to be drilled at slower speeds. However, the motor

must not be struggling with the operation. If the motor is

struggling DO NOT continue working, pull the drill clear of

the workpiece and run it on fast speed for a minute or so

allowing the motor time to cool down before you attempt

a little more of the work.

• If the job is too hard for the drill, do not continue,

otherwise permanent damage to the motor will occur.

• Concrete drilling should be carried out on the highest

speed.

DO NOT

overload motor when drilling concrete.

DO NOT

use too much pressure as the hammer action

relies on the drill bit being able to move back and forward in

the hole being drilled. Always clear the flutes of the drill bit

by removing it from the hole regularly.

WARNING.

This tool is not designed for high torque

applications such as screwdriving. Such use will damage

the motor.

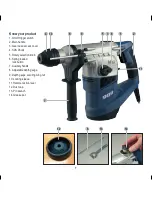

Gearbox maintenance

1. Carry out the following procedure after each period of

approximately 6 hours of use.

2. Remove the gear case access

cover (3) located on top of the

drill.

3. Use wrench (13) to unscrew

the gearbox cover.

4. Use a spatula or similar

instrument to apply general

machinery grease into the

gearbox cavity until it is full.

5. Be careful not to scratch or otherwise damage the

mechanism.

6. Replace the cover (3).

CAUTION.

Do not over-tighten cover (3) or overfill the

gearbox with grease. If you run out of grease, or are not

sure how to change the grease, please take your product to

the nearest authorised service centre and have a qualified

person replace the grease.

Maintenance

WARNING.

Always ensure that the tool is switched off and

the plug is removed from the power point before making any

adjustments or maintenance procedures.

1. Keep the tool’s air vents unclogged and clean at all times.

2. Regularly check to see if any dust or foreign matter has

entered the grills near the motor and around the trigger

switch. Use a soft brush to remove any accumulated

dust. Wear safety glasses to protect your eyes whilst

cleaning.

3. If the body of the drill needs cleaning, wipe it with a soft

damp cloth. A mild detergent can be used but nothing like

alcohol, petrol or other cleaning agent.

4. Never use caustic agents to clean plastic parts.

CAUTION.

Water must never come into contact with the

tool.

Summary of Contents for KHD1050K

Page 12: ......