8

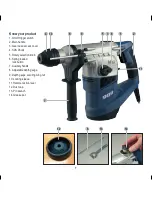

Auxiliary handle and depth gauge

1. Turn the auxiliary handle (7)

anticlockwise to loosen the

collar and slip it over the front

of the drill.

2. Loosen the wing nut (9)

and insert the depth gauge (8)

in the hole at the top

of the handle.

3. The auxiliary handle can be swiveled around 360° to

find the position that offers most comfort and the easiest

operation.

4. The depth gauge helps keep an accurate depth when

drilling holes to a set depth.

5. To change the position of the depth gauge, loosen the

wing nut (9) until the depth gauge is loose enough to

slide in the hole.

6. Place the tip of the drill on the workpiece and push in the

depth gauge until the desired hole depth is indicated on

the depth gauge scale.

7. Tighten the wing nut (9).

8. Check the depth with a steel rule for most accurate

measurement.

Using the dust protector cap

1. The dust cap (12) can be

used to give added protection

against dust and debris

entering the SDS chuck.

2. Place the cap over the shank

of the bit and slide it forward

until it rests against the

shoulder of the bit.

3. Insert the bit into the SDS

chuck as normal.

Selecting the required function

It is possible to use the Rotary Hammer Drill in three

different modes:

a. Rotation only – for drilling into metal and wood products.

b. Rotary hammer – for drilling into brick, concrete and

masonry products.

c. Hammer only – for chiseling brick, concrete and masonry

products.

1. To operate the rotary selection knob (5), first press in the

spring loaded lock button (6) and then turn the knob to

the left or to the right .

2. To select the required mode of operation set the rotary

selection knob (5) and the hammer action lever (11) to

the positions indicated in the following.

Summary of Contents for KHD1050K

Page 12: ......