9

Getting to know your belt and disc sander

WARNING:

To avoid injury from accidental start, turn switch

’OFF’ and remove plug from power source outlet before

making any adjustments.

1. Work Support. Supports the workpiece on the

sanding belt.

2. Hex Socket Head Screw. Loosening screw allows belt

bed to be raised to the vertical position.

3. Tracking Knob. Turning knob anti-clockwise causes

sanding belt to move towards the disc. Turning knob

clockwise causes sanding belt to move away from

the disc.

4. Tension Lever. Sliding lever to the right releases the

sanding belt tension; sliding lever to the left applies

belt tension.

5. Table Lock Knob. Loosening knob allows the work table

to be tilted for bevel sanding.

6. Auxiliary Mounting Hole. Allows table assembly to

be mounted for end sanding when bed is placed in

vertical position.

Mounting belt and disc sander to workbench

If belt and disc sander is to be used in a permanent

location, it should be fastened securely to a firm supporting

surface such as a workbench.

If mounting to a workbench, holes should be drilled through

supporting surface of the

workbench.

1. The unit should be bolted

securely using M8 screws and

hex nuts (not included). Screw

length should be 38mm plus

the thickness of the bench top.

2. Locate and mark the holes

where belt and disc sander is

to be mounted.

3. Drill (2) x 9.5 mm diameter holes though workbench.

4. Place belt and disc Sander on workbench aligning holes

drilled in workbench.

5. Insert two M8 screws and tighten hex nuts.

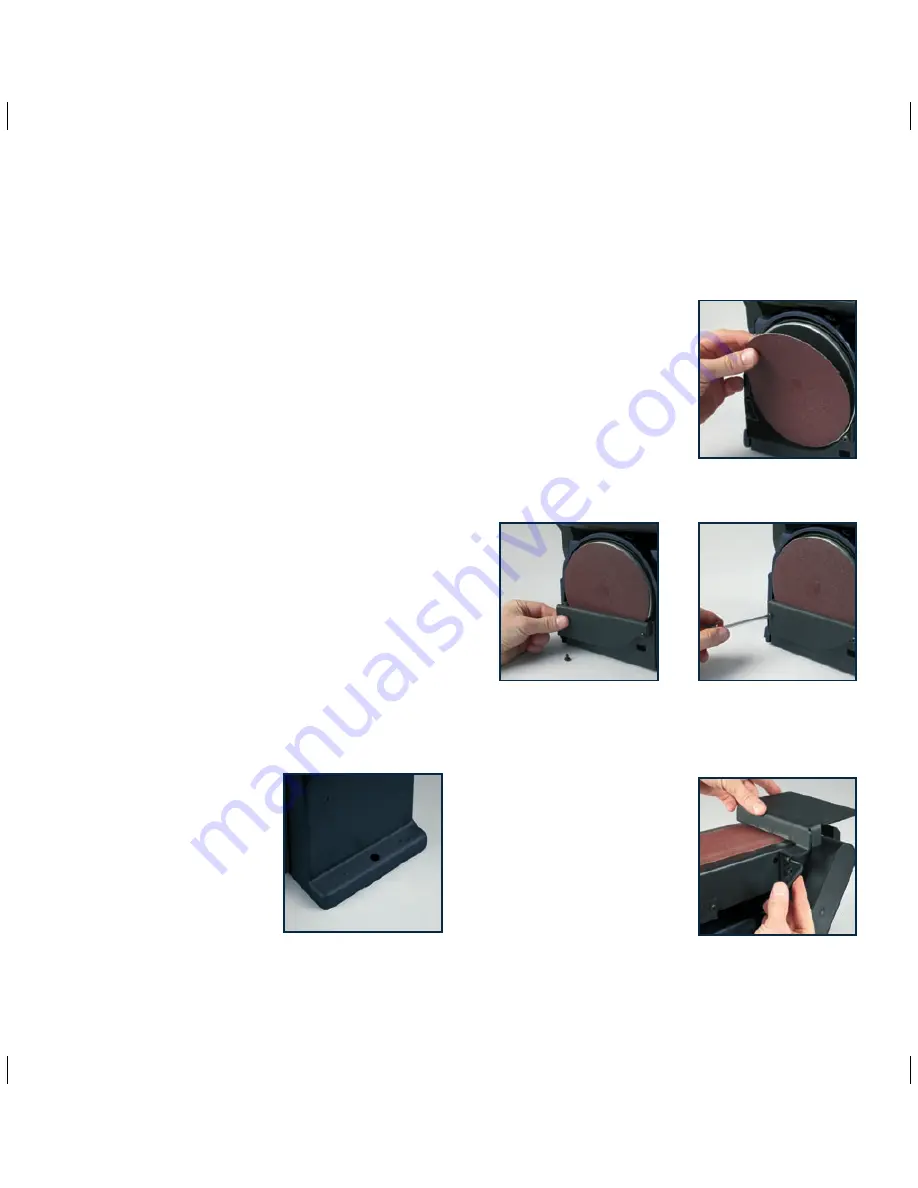

Installing sanding disc and guard

1. Remove the backing from

the sanding disc (7). Align

perimeter of disc with sanding

plate (8) and press disc

firmly into position all the way

around.

2. Locate disc guard (6) and two

M4.2 pan head screws.

3. Position disc guard against

lower 1/3 of disc aligning holes.

4. Using a Phillips screwdriver, fasten the pan head screws

securely, applying light pressure to thread the holes.

Installing work support

1. Using a wrench secure

work support (9) to side

of belt & disc sander using

M6 hex screw, lock washer

and washer.

2. Hold work support in position

and fasten.

Summary of Contents for TBD15009

Page 14: ......