11

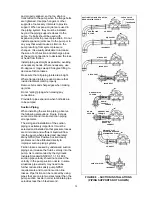

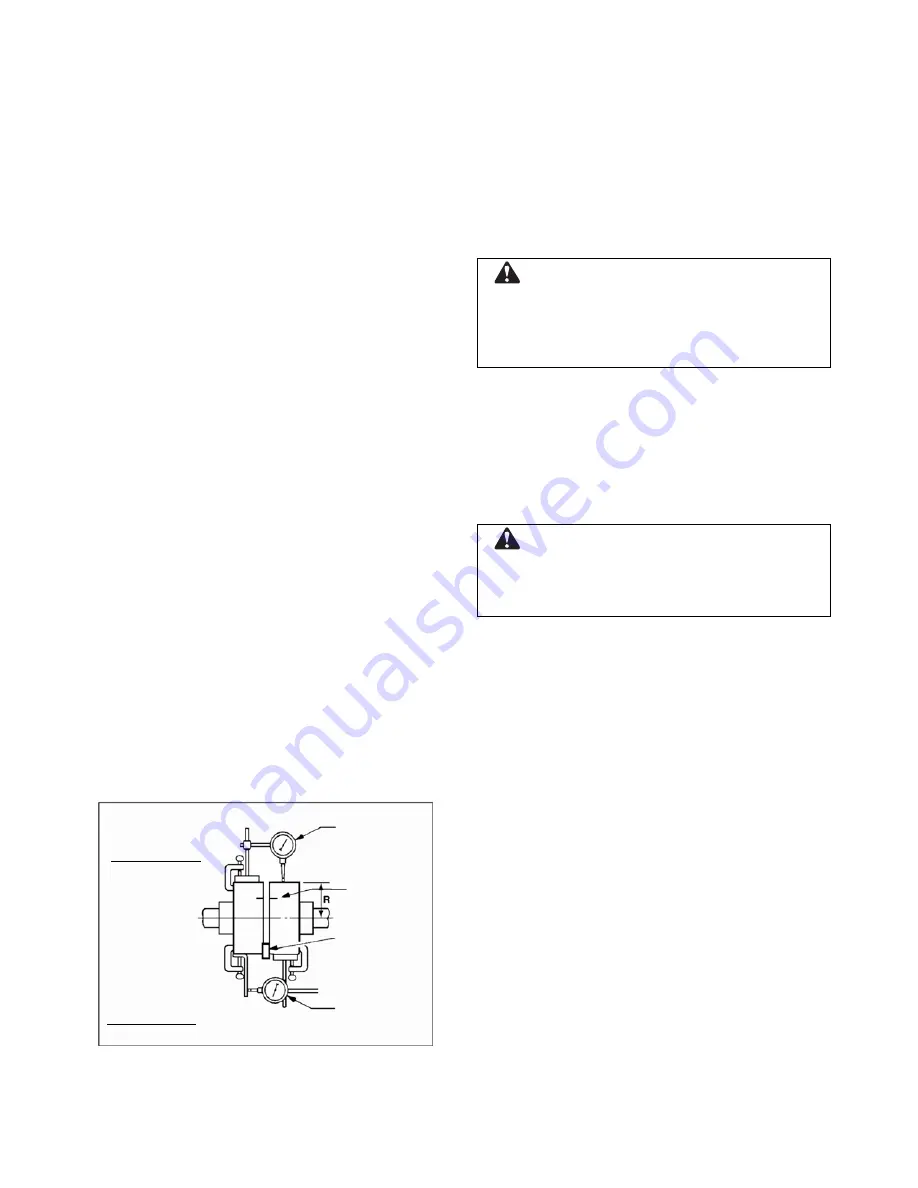

Method 2 – For Orange Hytrel Insert, 3500

RPM Operation, or All Other Coupler

Types

(See Figure 7B)

a. Make sure each hub is secured to its

respective shaft and that all connecting

and/or spacing elements are removed at

this time.

b. The gap between the coupling hubs is set

by the manufacturer before the units are

shipped. However, this dimension should

be checked. (Refer to the coupling

manufacturer’s specifications supplied

with the unit.)

c. Scribe index lines on coupling halves as

shown in Figure 7B.

d. Mount dial indicator on one hub as shown

for parallel alignment. Set dial to zero.

e. Turn both coupling halves so that index

lines remain matched. Observe dial

reading to see whether driver needs

adjustment (See paragraph i below).

f. Mount dial indicator on one hub as shown

for angular alignment. Set dial to zero.

g. Turn both coupling halves so that index

lines remain matched. Observe dial

reading to see whether driver needs

adjustment (See paragraph i below).

h. Assemble coupling. Tighten all bolts and

set screw(s). It may be necessary to

repeat steps c through f for a final check.

i. For single element couplings, a

satisfactory parallel misalignment is

.004"T.I.R., while a satisfactory angular

misalignment is .004"T.I.R. per inch of

radius R (See Figure 7B).

FIGURE 7B – CHECKING ALIGNMENT

(METHOD 2)

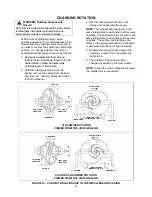

Final Alignment

Final alignment cannot be accomplished until

the pump has been operated initially for a

sufficient length of time to attain operating

temperature. When normal operating

temperature has been attained, secure the

pump to re-check alignment and compensate

for temperature accordingly. See Alignment

Section.

WARNING: Rotating Components

Hazard

Do not operate pump without all guards in place.

Failure to follow these instructions could result in

serious personal injury or death and property

damage.

OPTIONAL Alignment Procedure

If desired, the pump and motor feet can be

doweled to the base after final alignment is

complete. This should not be done until the

unit has been run for a sufficient length of

time and alignment is within the tolerance.

See Doweling Section.

CAUTION: Extreme Temperature and/or

Flying Debris Hazard

Eye protection and gloves required. Failure to

follow these instructions could result in property

damage and/or moderate personal injury.

NOTE:

Pump may have been doweled to

base at factory.

DOWELING

Dowel the pump and driving unit as follows:

a. Drill holes through diagonally opposite feet

and into the base. Holes must be of a

diameter 1/64 inch less than the diameter

of the dowel pins. Clean out the chips.

b. Ream the holes in feet and base to the

proper diameter for the pins (light push fit).

Clean out the chips.

c. Insert pins to be approximately flush with

feet.

SUCTION AND DISCHARGE PIPING

General

When installing the pump piping, be sure to

observe the following precautions:

Piping should always be run to the pump.

Do not move pump to pipe. This could make

final alignment impossible.

Both the suction and discharge piping should

be supported independently near the pump

DIAL

INDICATOR

INDEX LINE

RESILIENT

SEPARATOR

DIAL

INDICATOR

ANGULAR

ALIGNMENT

PARALLEL

ALIGNMENT