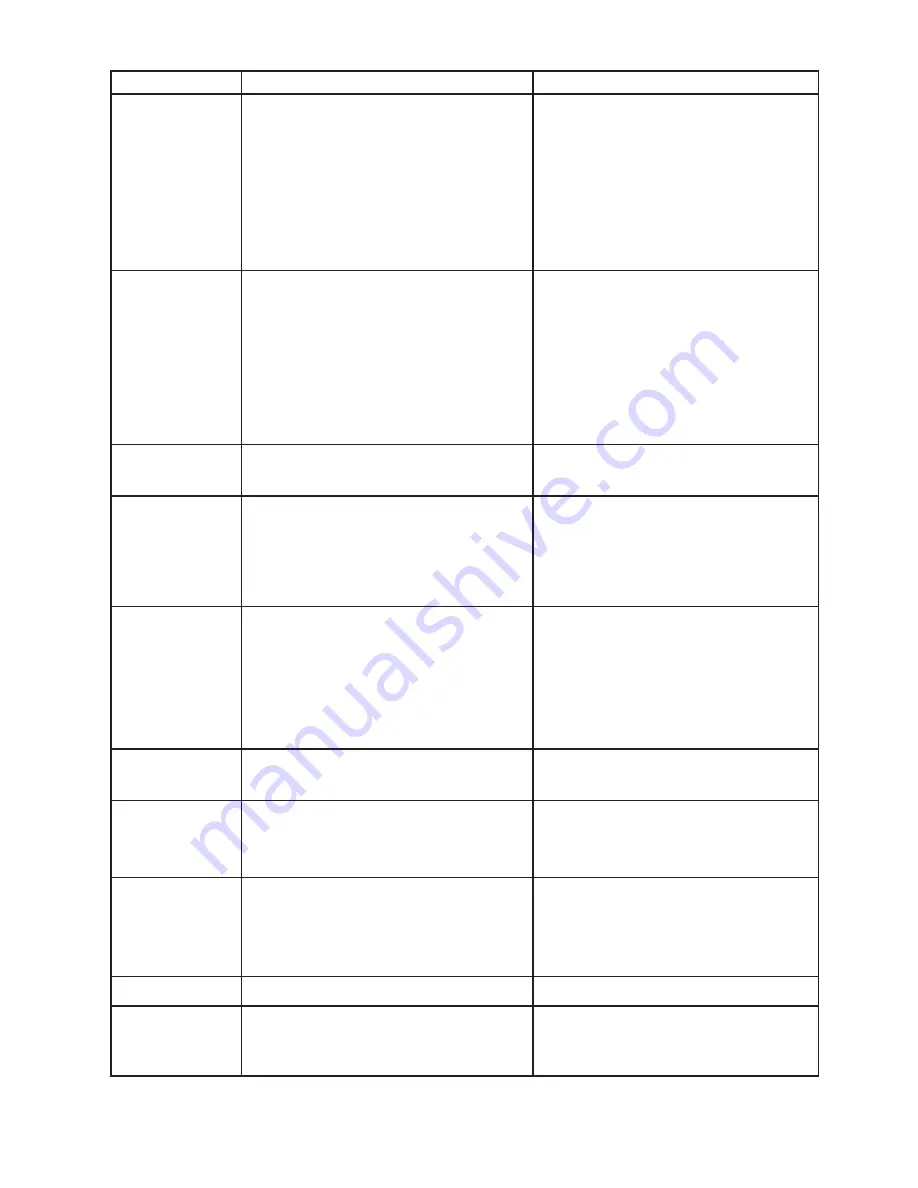

Problem

Possible Causes

Probable Solutions

Engine misfires

1. Spark plug cap loose.

2. Incorrect spark plug gap or

damaged spark plug.

3. Defective spark plug cap.

4. Old or low quality gasoline.

5. Incorrect compression.

1. Check wire connections.

2. Re-gap or replace spark plug.

3. Replace spark plug cap.

4. Use only fresh 87+ octane stabilizer-treated

unleaded gasoline.

Do not use gasoline with more than

10% ethanol (E15, E20, E85, etc.).

5. Diagnose and repair compression.

(Use Engine will not start:

COMPRESSION RELATED section.)

Engine stops

suddenly

1. Fuel tank empty or full of impure or low quality

gasoline.

2. Low oil shutdown.

3. Defective fuel tank cap creating vacuum,

preventing proper fuel flow.

4. Faulty magneto.

5. Disconnected or improperly

connected spark plug cap.

1. Fill fuel tank with fresh 87+ octane stabilizer-

treated unleaded gasoline.

Do not use gasoline with more than

10% ethanol (E15, E20, E85, etc.).

2. Fill engine oil to proper level.

Check engine oil before EVERY use.

3. Test/replace fuel tank cap.

4. Have qualified technician service magneto.

5. Secure spark plug cap.

Engine stops when

under heavy load

1. Dirty air filter

2. Engine running cold.

1. Clean or replace element.

2. Allow engine to warm up prior

to operating equipment.

Engine knocks

1. Old or low quality gasoline.

2. Engine overloaded.

3. Incorrect spark timing, deposit buildup,

worn engine, or other mechanical problems.

1. Fill fuel tank with fresh 87+ octane stabilizer-

treated unleaded gasoline.

Do not use gasoline with more than

10% ethanol (E15, E20, E85, etc.).

2. Do not exceed equipment’s load rating.

3. Have qualified technician diagnose and service

Engine backfires

1. Impure or low quality gasoline.

2. Engine too cold.

3. Intake valve stuck or overheated engine.

4. Incorrect timing.

1. Fill fuel tank with fresh 87+ octane stabilizer-

treated unleaded gasoline.

Do not use gasoline with more than

10% ethanol (E15, E20, E85, etc.).

2. Use cold weather fuel and oil additives

to prevent backfiring.

3. Have qualified technician diagnose

and service engine.

4. Check engine timing.

Generator shuts down

during operation

No AC output

Generator gallops

Repeated circuit

breaker tripping

Generator cannot

supply enough power

or overheating

1. Out of fuel.

2. Low oil level.

1. Generator is overloaded.

2. Insufficient ventilation.

1. Cable not properly connected.

2. Circuit breaker is open.

3. Faulty brush assembly.

4. Faulty AVR.

5. Loose wiring.

6. Other.

1. Engine governor defective.

1. Overload.

2. Faulty cords or device.

1. Fill fuel tank.

2. Fill crankcase to the proper level. Place

generator on a flat, level surface.

1. Review load and adjust, see“xx”.

2. Check for air restriction. Move to a well

ventilated area.

1. Check all connections.

2. Reset circuit breaker.

3. Replace brush assembly.

4. Replace AVR.

5. Inspect and tighten wiring connections.

6. Contact Customer Service at 1-855-888-3598.

1. Contact Customer Service at 1-855-888-3598.

1. Review load and adjust. See“Wattage Reference

Guide” on Page 10.

2. Check for damaged, bare or frayed wires.

Replace defective device.

engine.

17

Summary of Contents for SUA9000E

Page 4: ...4 ...

Page 5: ...call our Customer Service at 1 855 888 3598 please 5 ...

Page 9: ...The SAE Viscosity Chart 9 ...

Page 10: ...START 4 4 WATTAGE REFERENCE GUIDE Fuel Valve Turn Fuel Valve to ON position 10 ...

Page 13: ... MAINTENANCE section 13 ...

Page 15: ...Valve Clearance Intake 0 10 0 15mm 0 004 0 006 in Exhaust 0 15 0 20mm 0 006 0 008 in 15 ...

Page 19: ...SECTION 10 DIAGRAM SUA9000E 19 ...

Page 21: ...GENERAL DIAGRAM 21 ...

Page 23: ...ENGINE DIAGRAM 23 ...

Page 24: ...2016 2017 12 24 ...

Page 25: ...25 ...

Page 28: ......

Page 29: ...855 888 3598 626 225 8930 ...