Vertical contact toaster

14

P/N 1011097 Rev. A 03/12

A.J. Antunes & Co.

maIntenance (continued)

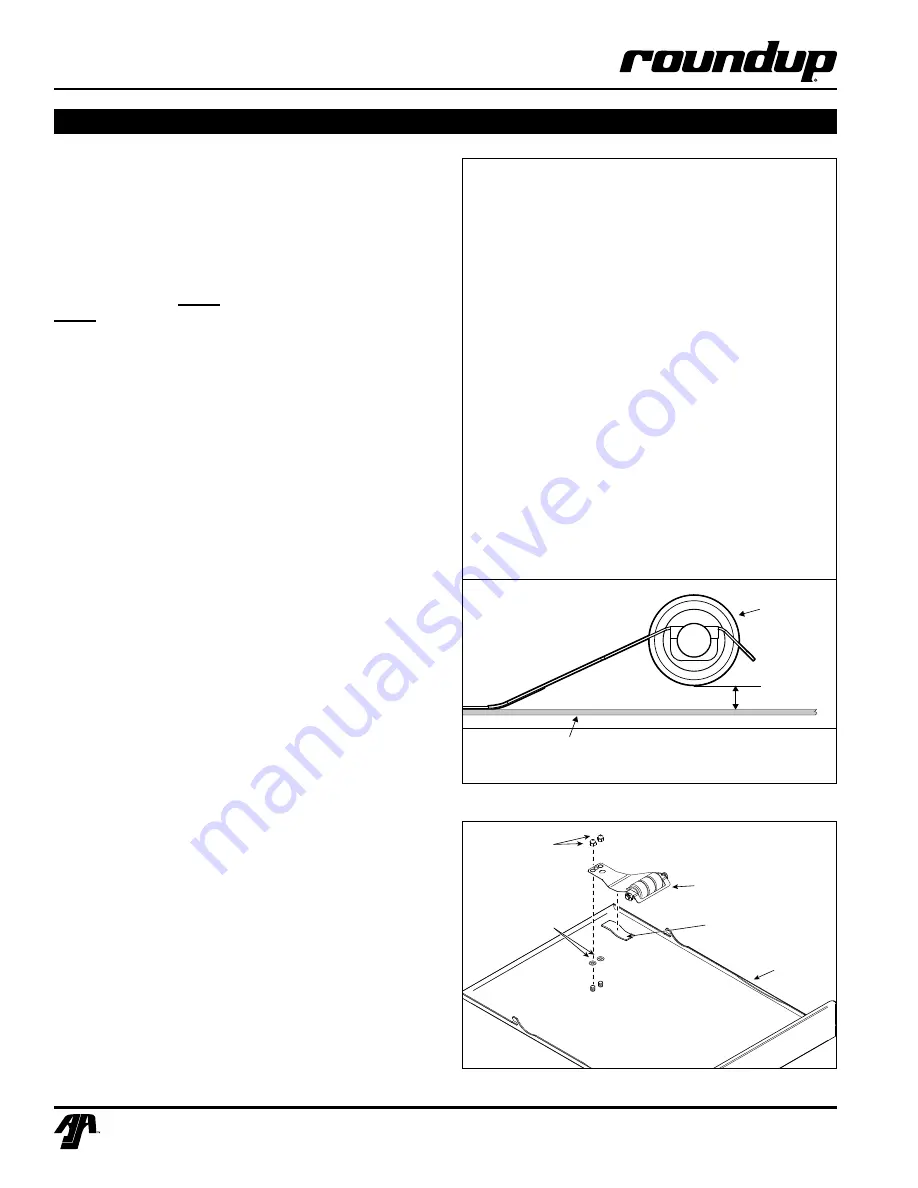

checking the roller tensioners

(every 3–6 months)

measUrInG the rOller tensIOners

1. Measure the Roller Tensioner on both inner

Conveyor Covers (Figure 14).

2. The space between the inner Conveyor Cover

and bottom of the Tensioner wheel should be no

larger than 1/2 inch.

3. Adjust or replace tensioners as needed.

replacInG/aDJUstInG the rOller tensIOners

1. Remove the acorn nuts and old Roller Tensioner

Assembly.

2. Install the new Tensioner Assembly according to

Figure zx.

3. Make sure the spacers are placed inside the

Tensioner arm. The spacers allow the Tensioner

to pivot freely.

4. Make sure there is 1/2” between the bottom of the

Tensioner wheel and the inside of the Conveyor

Cover.

1/2 Inch

Roller

Tensioner

Assy.

Inner Surface

of Conveyor cover

figure 13. measuring roller tensioner

Acorn Nuts

Roller

Tensioner

Assy.

Tape

Spacers

Rear

Conveyor

Cover

NOTE

:

Installation is the

same for both the Front

and Rear Conveyor Covers

8. Replace the Master Links on both the left and

right side of the chain. This connects the two ends

of the chain together.

nOte: the ends of the hooks must point down

(figure 13).

6. Replace the Belt Wrap. Secure with Hinge Pin.

nOte: make sure the conveyor belt chain and belt

wrap is installed

under

the upper support rod and

under

the lower support rod.

7. Replace the Conveyor Cover(s), Butter Wheel

assembly, Bun Chute, and Heat Shield.

8. Set the Bun Compression Adjustment Knobs to 4

& 6. Replace the Bun Compression Cover Plate.

9. Return the unit into service.

replacInG the cOnVeyOr belt chaIns

1. Turn the unit off, unplug the power cord, and allow

the unit to cool.

2. Remove the Butter Wheel Assembly, Bun Chute,

and Heat Shield (Figure 1). Remove the Bun

Compression Cover Plate and set the Bun

Thickness Compression Knobs to 6 & 6.

3. Remove the Conveyor Cover(s) and pull the Belt

Wrap Hinge Pin out of the zipper (Figure 9).

4. Pull the Conveyor Chain away from the edge of

the toaster (Figure 12). Remove the Belt Wrap(s).

5. Locate the two Master Links on the Conveyor

Belt Chain and remove both the left and the right

Master Link.

6. Remove the existing Conveyor Belt Chain(s).

7. Place the new Conveyor Belt Chain(s) on the top

sprockets with the hook ends down

nOte: the ends of the hooks must point down

(figure 13).

8. Wrap the Conveyor Belt Chain around the top and

lower sprockets and connect by replacing both the

left and the right Master Links (Figure zx).

9. Replace the Conveyor Cover(s), Butter Wheel

Assembly, Bun Chute, and Heat Shield.

10.

Set the Bun Compression Adjustment Knobs to

4 and 6. Replace the Bun Compression Cover

Plate.

11. Return the unit to service.

figure 14. measuring roller tensioner