VZN V SERIES

13

P/N 1011079 Rev. J 01/14

INSTALLATION (continued)

Rinsing the Ultra Filter Cartridge

The Ultra Filter Cartridge comes pre-installed in the VZN

system. The Ultra Filter Cartridge must be rinsed before the

system is used to remove any air and protective solution.

NOTE: Ultra Filter Cartridge must be rinsed to drain

before use. Rinsing to drain removes storage solution

and air. Do NOT rinse into carbon if present. Carbon life

and/or performance may be affected.

NOTE: Make sure the Carbon Element and TAC Cartridge,

if present, are NOT installed. These should only be

installed after the Ultra Filter Cartridge has been rinsed.

1. Direct water from the Rinse Ball Valve to a drain.

2. Close the Outlet Ball Valve.

3. Close the Inlet Ball Valve.

4. Open the Rinse Ball Valve.

5. Slowly turn on the water supply to the VZN system.

6. Slowly open the Inlet Ball Valve. Air and water will come

out of the Rinse Ball Valve.

7. Press the

FLUSH

button. The Drain Valve will open and

air and water will come out of the drain line. Repeat six

times to ensure all air and storage solution are flushed

out of the Ultra Filter Cartridge.

8. Continue to allow water to run at full flow out of the

Rinse Ball Valve for at least 15 minutes.

9. After 15 minutes, close the Rinse Ball Valve and allow

the system to sit for 15 minutes without any water

flow to release any trapped air from the Ultra Filter

Cartridge.

10. Inspect the unit for any leaks, repairing as needed.

11. After 15 minutes, open the Rinse Ball Valve and wait for

five minutes to flush out any remaining air.

12. Close the Rinse Ball Valve and disconnect the garden

hose.

13. Press the

FLUSH

button to open the Drain Valve.

Repeat six times to ensure any remaining air is flushed

out of the system.

14. Open the closest downstream tap or faucet.

15. Slowly open the Outlet Ball Valve and allow water to run

through the system and out the faucet for five minutes.

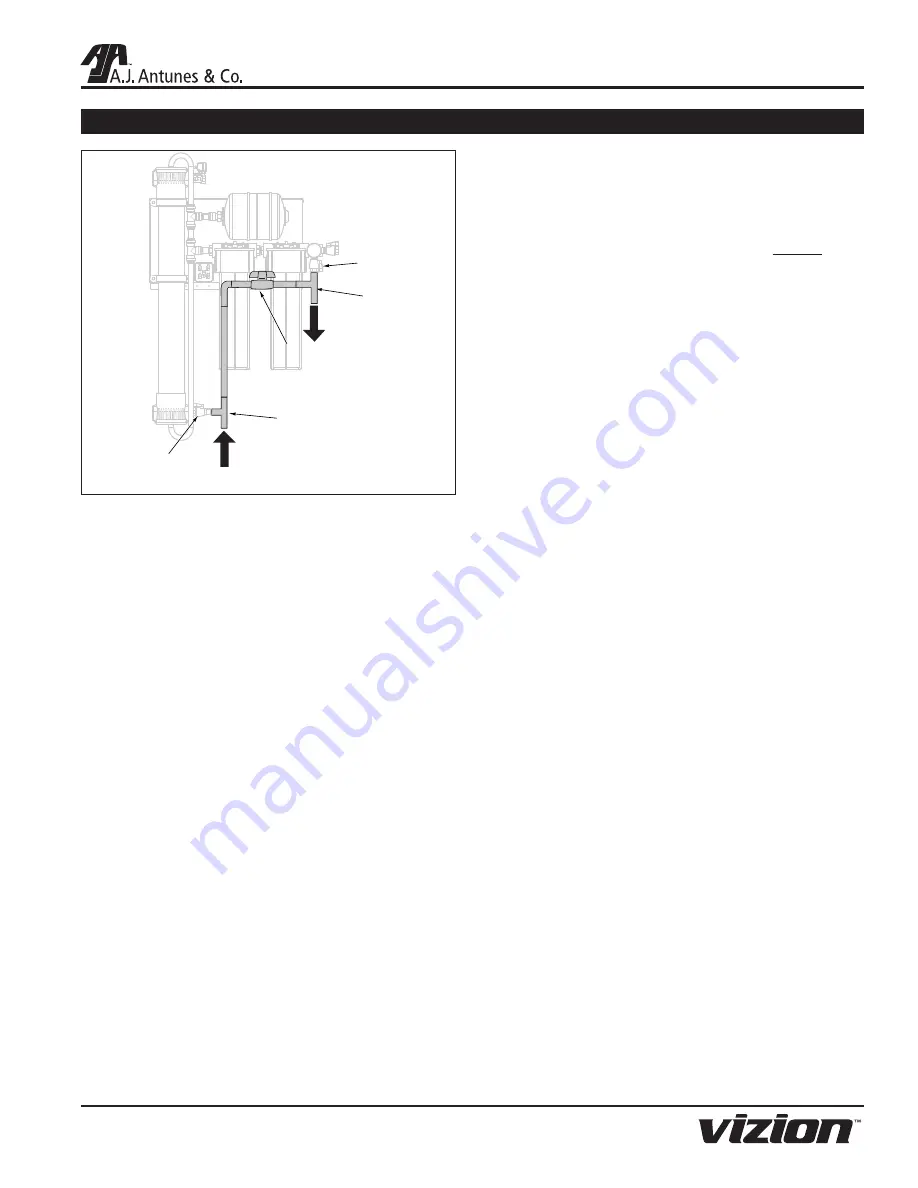

Water

Flow

Inlet Ball

Valve

(Manual)

Tee

Tee

Water

Flow

Outlet Ball

Valve

(Manual)

Fully

Ported

Ball Valve

Figure 7. Install Bypass

Installing a Bypass

It is recommended that an optional bypass be installed to help

with replacing cartridges and servicing the system. Installation

of a bypass can be done easily as the Inlet and Outlet Ball

Valves are already installed.

1. Install tees on the end of the plumbing leading to the

Inlet and Outlet Ball Valves.

2. Connect the two tees by installing plumbing and a fully

ported (preferably 3/4”) Ball Valve.

3. When the system is in use, open the Inlet and Outlet

Ball Valves and close the Bypass Ball Valve.

4. When servicing is needed, close the Inlet and Outlet Ball

Valves and open the Bypass Ball Valve.

Starting the Controller

1. Select the proper AC plug for your electrical outlet and

install it onto the power supply.

2. Plug the appropriate end of the power cord into the

controller.

3. Plug the other end of the power cord into the electrical

outlet. The LEDs on the controller will light up.

4. The controller automatically enters Flush Mode and the

Flush LED starts to flash.

5. When flushing is complete, the Flush LED will stop

flashing and one or more LEDs will remain lit, indicating

the unit has power and which interval is selected in the

controller.