21

provide an adequate supply of fresh air the water heater

must be installed in a Direct Vent configuration.

2.

if the water heater is to be installed in a beauty shop,

barber shop, cleaning establishment, a laundry with dry

cleaning equipment or any space with contaminated air it is

imperative that the water heater(s) be installed in a Direct

Vent configuration so that all air for combustion is derived

from the outdoor atmosphere.

3.

The vent and intake air piping must terminate outdoors.

4.

The minimum clearance from combustible materials for the

vent (exhaust) and intake air piping shall be 0 inches. Vent

piping passing through a combustible wall or ceiling must be

a continuous run (no joints).

5.

The water heater must be protected from freezing downdrafts

during shutdown periods.

6.

The vent (exhaust) pipe must not be combined or connected

to any other appliance’s vent system or chimney.

7.

The intake air pipe must not be combined or connected to

any other appliance’s intake air piping.

8.

Locate the water heater where the vent (exhaust) and intake

air piping will remain within the maximum equivalent lengths

allowed. See Venting requirements on page 22.

9.

Do not install the vent or intake air piping in a manner that will

allow water to be trapped in the piping.

10.

Vent pipes must be pitched a minimum of a 1/4 inch per foot

back to the water heater (to allow drainage of condensate).

11.

Do not anchor the vent or intake air pipe directly to framed

walls, floors or ceilings unless rubber isolation pipe hangers

are used to prevent vibration noise from being transmitted.

12.

Use only approved vent/intake air pipe sizes and materials.

See Venting Requirements on page 22.

13.

Use only factory supplied vent and intake air or concentric

terminations. See the Venting Requirements on page 22.

14.

Do not locate the vent (exhaust) or intake air terminations

where they would be objectionable due to noise at the

termination(s). This includes locations close to or across from

windows and doors.

15.

Direct venting into dead air spaces such as alleys, atriums,

and inside corners can cause recirculation of flue gases.

recirculation of flue gases will cause sooting, premature

failure of the heat exchanger and icing of the combustion

air intake during severe cold weather. To prevent the

recirculation of flue gases, maintain as much distance as

possible between the intake air and vent terminations.

16.

Do not locate the vent termination over a public area where

condensate or vapor can cause a nuisance or ice hazard.

17.

Ensure the screens in the factory supplied terminations are

securely installed to prevent blockage in the vent system.

18.

Stress levels in pipe/fittings can be significantly increased by

improper installation. if rigid pipe clamps are used to hold

the pipe in place, or if the pipe cannot move freely through a

wall penetration, the pipe may be stressed, or high thermal

stresses may be formed when the pipe heats up and expands.

install accordingly to minimize such stresses.

19.

Carefully read the Venting requirements on page 22 and then

proceed to the Venting installation Sequence on page 23.

Venting installation

Breathing carbon monoxide can cause brain damage or death.

Always read and understand the instruction manual.

Install vent system in accordance with codes.

Do not operate water heater if flood damaged.

Special consideration must be taken with installations

above 10,000 feet (3,048 m) refer to high altitude

section of this manual.

Breathing Hazard - Carbon Monoxide Gas

•

•

Do not operate if soot buildup.

•

Do not obstruct water heater air intake with insulating

jacket or blanket.

•

Do not place chemical vapor emitting products near

water heater.

•

Gas and carbon monoxide detectors are available.

•

Never operate the heater unless it is vented to the

outdoors and has adequate air supply to avoid risks

of improper operation, fire, explosion or asphyxiation.

•

Analyze the entire vent system to make sure that

condensate will not become trapped in a section of

vent pipe and therefore reduce the open cross

sectional area of the vent.

•

•

Never operate the water heater unless it is vented to the outdoors.

The instructions in this section of the manual must be followed

to avoid choked combustion or recirculation of flue gases. Such

conditions cause sooting of the combustion chamber, burners

and flue tubes and creates a risk of asphyxiation.

general Venting information

The water heaters covered in this manual are operationally

equivalent to Category iV appliances and may be installed in

either a Power Vent or Direct Vent configuration.

category iV appliance

Category iV appliances operate with a positive vent (exhaust)

static pressure and with vent gas temperatures low enough to

produce condensate in the vent piping.

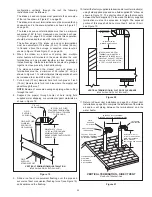

power Vent configuration

Power Vent configurations derive all combustion air from the

room where they are installed and discharge all flue gases to

the outdoor atmosphere through a sealed vent (exhaust) pipe.

Power vent configurations have one vent pipe connected to the

water heater which can be terminated in a vertical or horizontal

arrangement. See Figure 40 and Figure 41 on page 32.

direct Vent configuration

Direct Vent configurations derive all combustion air directly from

the outdoor atmosphere through a sealed intake air pipe and

discharge all flue gases to the outdoor atmosphere through a

sealed vent (exhaust) pipe. Direct Vent configurations have two

pipes connected to the water heater, one vent pipe and one

intake air pipe. Direct Vent configurations can be terminated

in one of six different arrangements. See Figure 42 on page 32

general Venting instructions

These instructions must be followed on all installations.

1. Do NoT

install the water heater in a Power Vent configuration

unless there is adequate supply of fresh air, see Air

requirements on page 17. if the installation space does not

Summary of Contents for 101 Series

Page 75: ...75...