6

recommendations of serving gas supplier. Refer to the latest

edition of ANSI Z223.1.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to thermostat gas inlet.

The thermostat inlet has a pad for use with a backup wrench.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases. Do not use teflon tape on thermostat fittings.

DISCONNECT THE APPLIANCE AND ITS INDIVIDUAL SHUT

OFF VALVE FROM THE GAS SUPPLY PIPING SYSTEM DURING

ANY SUPPLY PRESSURE TESTING EXCEEDING 1/2 PSI

(3.5 kPa). GAS SUPPLY LINE MUST BE CAPPED WHEN

DISCONNECTED FROM THE HEATER. FOR TEST

PRESSURES AT 1/2 PSI (3.5 kPa) OR LESS, THE APPLIANCE

NEED NOT BE DISCONNECTED, BUT MUST BE ISOLATED

FROM THE SUPPLY PRESSURE TEST BY CLOSING THE MAIN

MANUAL GAS VALVE.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE. USE SOAP AND WATER SOLUTION OR OTHER

MATERIAL ACCEPTABLE FOR THIS PURPOSE. DO NOT USE

MATCHES, CANDLES, FLAME OR OTHER SOURCES OF

IGNITION TO LOCATE GAS LEAKS.

DRAFT HOOD

THE DRAFT HOOD INCLUDED WITH THE HEATER MUST BE

INSTALLED PROPERLY FOR SAFE OPERATION.

Locate draft hood as seen in figure 1. Position draft hood over

the flue tube. Align the draft hood legs with the four holes

surrounding the flue. Insert tabbed end of legs into the

corresponding holes and twist to lock the draft hood in place.

When installing vent piping, secure the vent pipe to the draft

hood using at least three sheet metal screws in the draft hood

outlet.

VENTING

THE HEATER WITH DRAFT HOOD INSTALLED AS SHOWN IN

FIG. 1 MUST BE CONNECTED TO A CHIMNEY OR GAS VENT.

The vent pipe from the heater to the chimney must not be smaller

than the outlet of the draft hood on the heater and should slope

upward to the chimney at least 1/4 inch per foot. Do not extend

vent pipe beyond the inside wall of the chimney.

For proper venting in certain installations, a field installed

increased size vent connector and pipe size may be needed.

Consult vent tables in the latest edition of the National Fuel Gas

Code ANSI Z 223.1

WARNING

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO

THE OUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID

RISKS OF IMPROPER OPERATION, FIRE, EXPLOSION OR

ASPHYXIATION.

RELIEF VALVE - FIG. 1

A NEW TEMPERATURE AND PRESSURE RELIEF VALVE

COMPLYING WITH THE STANDARD FOR RELIEF VALVES AND

AUTOMATIC GAS SHUT OFF DEVICES FOR HOT WATER

SUPPLY SYSTEMS, ANSI Z21.22 (LATEST EDITION) MUST BE

INSTALLED IN THE HEATER IN THE MARKED OPENING

PROVIDED. THE VALVE MUST BE OF A SIZE (INPUT RATING)

THAT WILL BE ADEQUATE FOR YOUR SIZE HEATER.

Check the metal tag on the relief valve and compare it to the

heater’s rating plate. The pressure rating of the relief valve

must not exceed the working pressure shown on the rating

plate of the heater. In addition, the hourly Btu rated temperature

steam discharge capacity of the relief valve shall not be less

than the input rating of the heater.

NO VALVE IS TO BE PLACED

BETWEEN THE RELIEF VALVE AND TANK. DO NOT PLUG

THE RELIEF VALVE.

The drain line connected to this valve must not contain a reducing

coupling or other restriction and must terminate near a suitable

drain to prevent water damage during valve operation. The

discharge line shall be installed in a manner to allow complete

drainage of both the valve and line.

DO NOT THREAD, PLUG

OR CAP THE END OF THE DRAIN LINE.

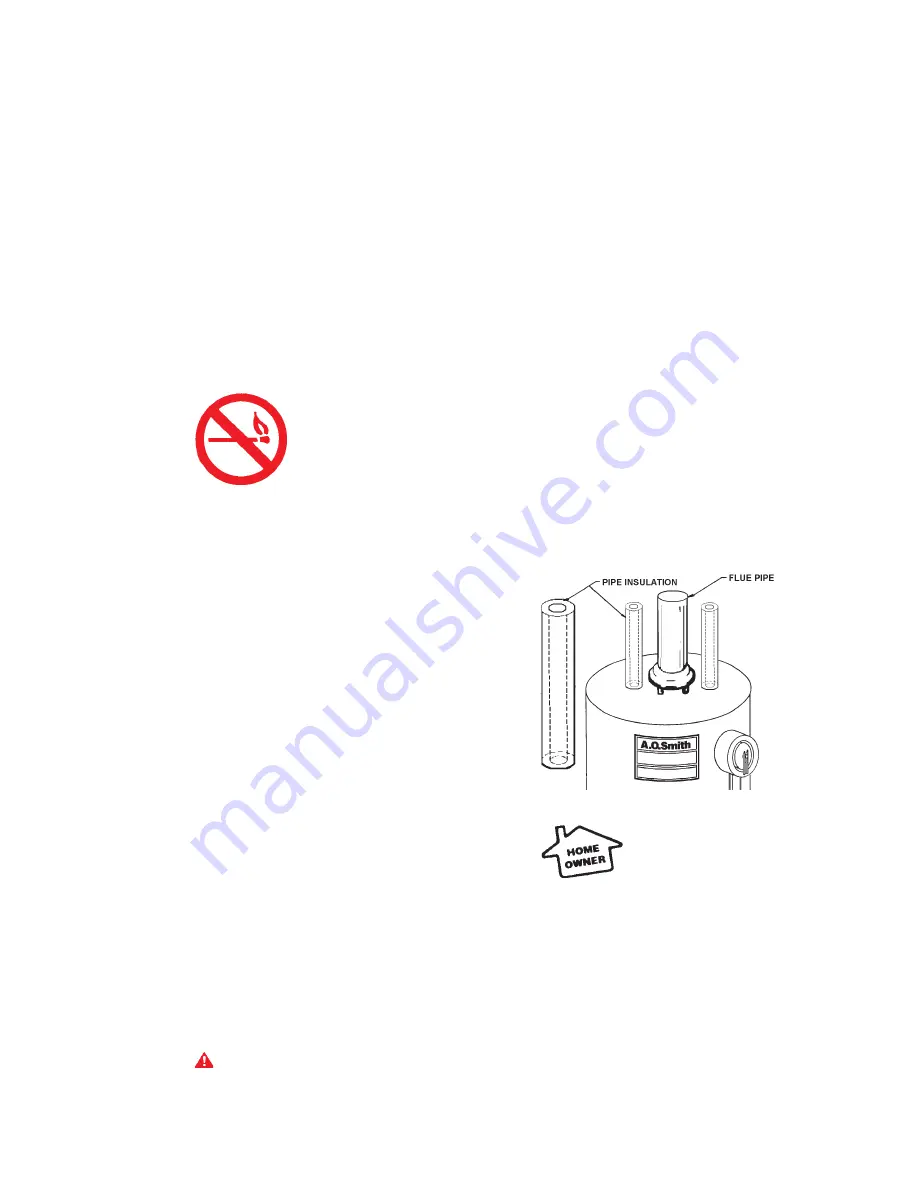

PIPE INSULATION - INSTALLATION

(SELECTED MODELS)

1. Remove pipe insulation from carton.

2. Fit pipe insulation over the incoming cold water line and

the hot water line. Make sure that the insulation is against

top cover of heater.

FIGURE 3

OPERATION

NEVER OPERATE THE HEATER WITHOUT FIRST BEING

CERTAIN IT IS FILLED WITH WATER AND A TEMPERATURE

AND PRESSURE RELIEF VALVE IS INSTALLED IN THE RELIEF

VALVE OPENING OF THE HEATER. DO NOT ATTEMPT TO

OPERATE HEATER WITH COLD WATER INLET VALVE CLOSED.

FILLING

1. Close the heater drain valve by turning handle clockwise,

Fig. 1.

2. Open a nearby hot water faucet to permit the air in the system

to escape.

3. Fully open the cold water inlet pipe valve allowing the heater

and piping to be filled, Fig. 1.

4. Close the hot water faucet as water starts to flow.

5. The heater is ready to be operated.