28

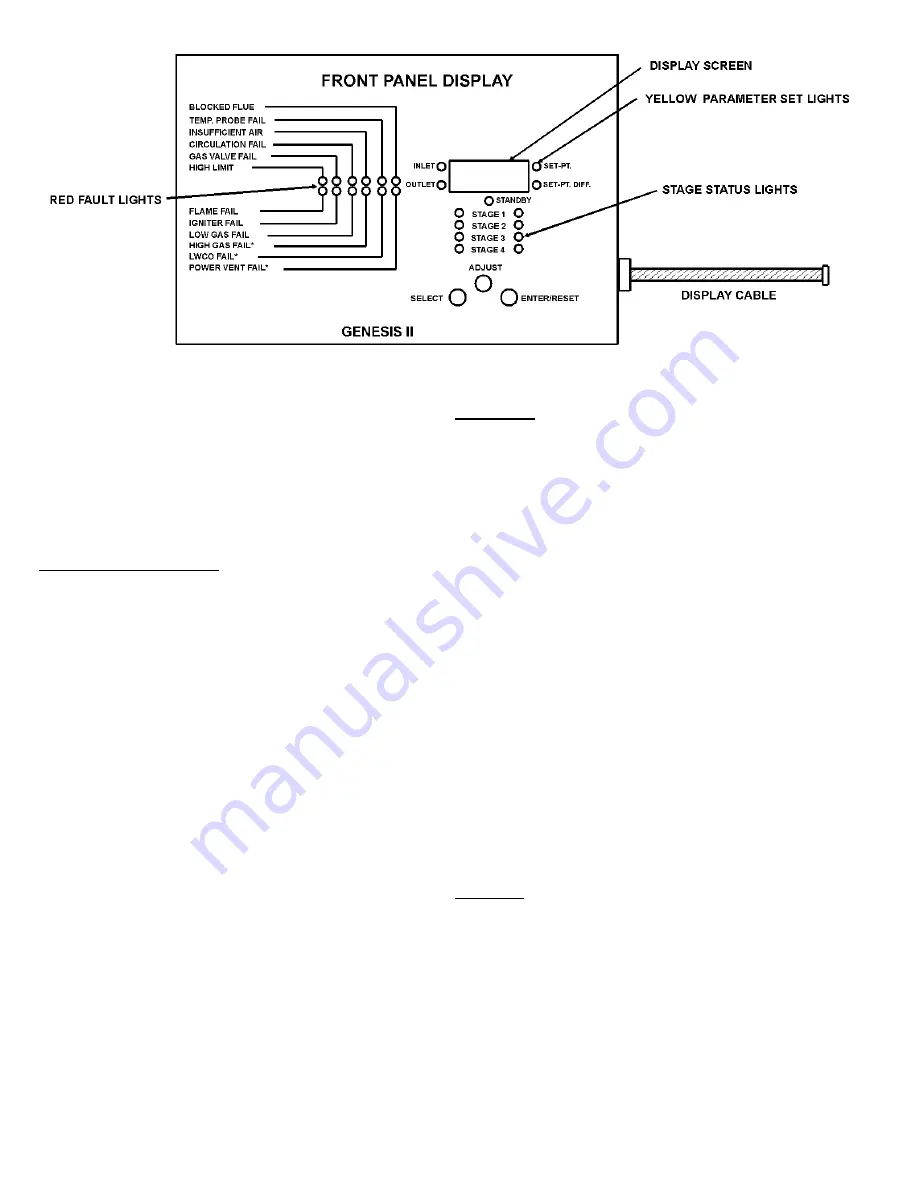

Figure 16. Display Board

High Gas Fail: Gas Pressure at Manifold too High

LWCO: Low water Cutoff activated. Not enough water.

Power Vent Fail: Not Enough Air to Close Switch

Stage One: Failure on Stage One

Stage Two: Failure on Stage Two

Stage Three: Failure on Stage Three

Stage Four: Failure on Stage Four

Yellow Parameter Set Lights

The five yellow parameter set lights allow the user to view system

set points and options. In conjunction with the four green stage

LEDs, the user can monitor and change settings on the various

stages. (See Figure 16.)

Inlet*:

Temperature shown is Inlet Water

Temperature.

Outlet:

Temperature shown is Outlet Water

Temperature.

Set-Point**:

Indicated probe set-point is being

displayed.

Set-Point Differential:

Shows differentials of each stage.

Standby:

Indicates Set-Point is Satisfied. Boiler

in Idle State.

*Defaults to tank probe temperature when Dip Switch "D" on

Central Control Board is Switched to the "ON" position.

(See Figure 14.)

**Shows set-point temperatures for Inlet/Tank or Outlet in

conjunction with yellow parameter lights. See temperature

probe section below.

TEMPERATURE PROBES

All units come with two temperature probes connected to the Inlet/

Outlet header. Additionally, an optional tank probe (thermistor type)

or 24V thermostat/aquastat can be connected to the unit. The probes

can be categorized as two types: controlling probes and safety

limit probes. Controlling probes can control the staging of the

boiler. Safety limit probes are used as resettable high limit switches.

The two controlling probes are the inlet probe and the tank probe.

The function and setting of the probes is further described in the

following sections.

Outlet Probe

The Outlet Temperature/ECO probe is located on the left side of the

header and has two sets of wires embedded in it. The black wires

sense the temperature at the probe. Their output is shown on the

display screen when the "OUTLET" LED is illuminated. The red

wires control the ECO (Emergency Cutoff) which shuts down the

unit if the water temperature exceeds 250°F (121°C) and requires

a manual reset of the boiler. The outlet probe functions as a

automatically resettable high limit and is not considered a controlling

probe on the boiler, which means it cannot be set to control the

staging of the unit. Depending on the application of the boiler, the

probe is set to one of two settings. In GW applications, the maximum

Outlet Set Point is 210°F (99°C) and in GB applications it is 240°F

(115°C). The Outlet probe Set Point can be adjusted between

these two values using Dip Switch "F" on the Central Control Board

inside the control box. (See Figure 14.)

To view the current programmed temperature set-point for the Out-

let Temperature probe:

1.

Press the SELECT push-button on the display board until both

the Set-Pt LED and Outlet Water Temperature LED (see

Figure 16) are illuminated.

2.

The LED display will show the current set-point temperature.

Note:

Under no circumstances should the Outlet/ECO be set

to exceed 210°F (99°C) in applications where the boiler

is heating potable water. Failure to observe this will

void the warranty.

Inlet Probe

The Inlet probe is located on the right side of the Inlet/Outlet header.

It has one set of blue wires embedded in it which senses the

temperature at the probe. The Inlet Probe is considered a controlling

probe and can be used to control the staging of the unit. The inlet

probe set-point is fully adjustable between the factory set minimum

value of 80°F (25°C) and a user controlled maximum value which

will depend on unit's application. In GW applications, the maximum

Inlet Set-Point is 190°F (88°C) and in GB application it is 220°F

(104°C). The Inlet probe Set-Point can be adjusted between these

two maximum values using Dip Switch "G" on the Central Control

Board which is located inside the control box. (See Figure 14.)

To change or view the current programmed temperature set-point

for the Inlet Temperature probe value: