29

1.

Press the SELECT push-button on the display board until both

the Set-Pt LED and Inlet Water Temperature LED (see

Figure 16) are illuminated.

2.

The LED display will show the current set-point temperature.

3.

Press and hold the ADJUST push-button. The displayed

temperature will either increase or decrease. To alternate

between increasing or decreasing the temperature, release

then press and hold the ADJUST push-button.

4.

When the desired set-point temperature is reached, release

the ADJUST push-button.

5.

Press the ENTER/RESET push-button once, this enters the

selected set-point temperature into controller memory.

6.

The appliance will now control the temperature to the desired

set-point value.

7.

For setting the stage differentials, see the section labeled

Procedure for Setting Stage Differential.

NOTE:

The boiler must complete a full cycle in order for the

new setting to take effect. If the unit is turned off prior

to a complete cycle the setting will be lost and the

previous setting will remain in effect.

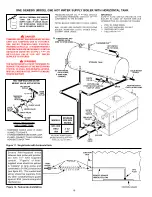

24 VAC System Controller (Optional)

A 24 VAC thermostat/aquastat can be implemented as a system

controller on Genesis units. The connection for such devices is

located in the 24 VAC junction box at the rear of the unit. A 24 VAC

thermostat/aquastat can only be used as an "On/Off" switch for the

unit. The actual controlling of the staging will be through either the

inlet or tank probe. To use a 24 VAC system controller, dip switch "E"

on the CCB must be switched to the "on" position. See Figure 14.

Tank Probe (Optional)

In addition to the Inlet and Outlet/ECO Probes, units can be

optionally equipped with a tank Probe. The connection for the tank

probe is located in the 24 VAC junction box at the rear of the unit.

The tank Probe can be configured to control the staging of the unit.

See Tank Probe Installation section on page 17 for additional

information.

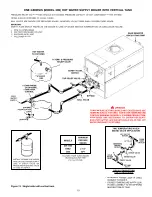

Procedure for Setting Tank Probe Temperature

If you have a GW hot water supply boiler, and have installed the tank

probe, below are the instructions on how to adjust the water

temperature set-point.

1.

Press the SELECT push-button on the display board until both

the Set-Pt LED and Inlet Water Temperature LED (see

Figure 16) are illuminated.

2.

The LED display will show the current set-point temperature.

3.

Press and hold the ADJUST push-button. The displayed

temperature will either increase or decrease. To alternate

between increasing or decreasing the temperature, release

then press and hold the ADJUST push-button.

4.

When the desired set-point temperature is reached, release

the ADJUST push-button.

5.

Press the ENTER/RESET push-button once, this enters the

selected set-point temperature into controller memory.

6.

The appliance will now control the temperature to the desired

set-point value.

7.

For setting the stage differentials, see the section labeled

Procedure for Setting Stage Differential.

Procedure for Setting Stage Differential

Once the system control and set-point temperature has been

entered, the switching differentials for the staging of the unit must

be established. To facilitate proper operation and maximize

appliance performance, each stage has a programmable

operating switching differential or “hysteresis” about the set point.

This means a call for heat for a particular stage will become active

when the water temperature measured at the controlling

temperature sensing probe drops to the set-point value minus the

switching differential value. It is necessary to set three set-point

differential values for three stage units and four for four stage. The

burner will remain on until the water temperature measured at

controlling probe reaches the stage set-point value. The switching

differential value is fully programmable from 0° F to 20°F (0°C to

11°C) using the push-button(s) located on the Display Board.

To change or view the current programmed switching differential:

1.

Press the SELECT push-button on the display board until both

the Set-Pt Diff. and green Stage One LED (see Figure 16) are

illuminated.

2.

The LED display will show the current differential for stage

one.

3.

Press and hold the ADJUST push-button. The displayed value

will either increase or decrease. To alternate between

increasing or decreasing the differential, release then press

and hold the ADJUST push-button.

4.

When the desired Set-Pt differential is reached, release the

ADJUST push-button.

5.

Press the ENTER/RESET push-button once, this enters the

selected set-point deferential into controller memory. To view

the Set-Pt minus the Set-Pt differential, press and hold the

"ENTER" push-button. This will be the "turn-on" temperature

for Stage One and the "turn-off" temperature for Stage Two.

6.

Repeat steps 2 through 5 for the rest of the stages.

7.

The appliance will now control temperature utilizing the

desired differentials.

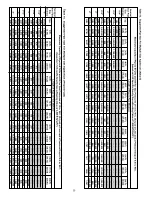

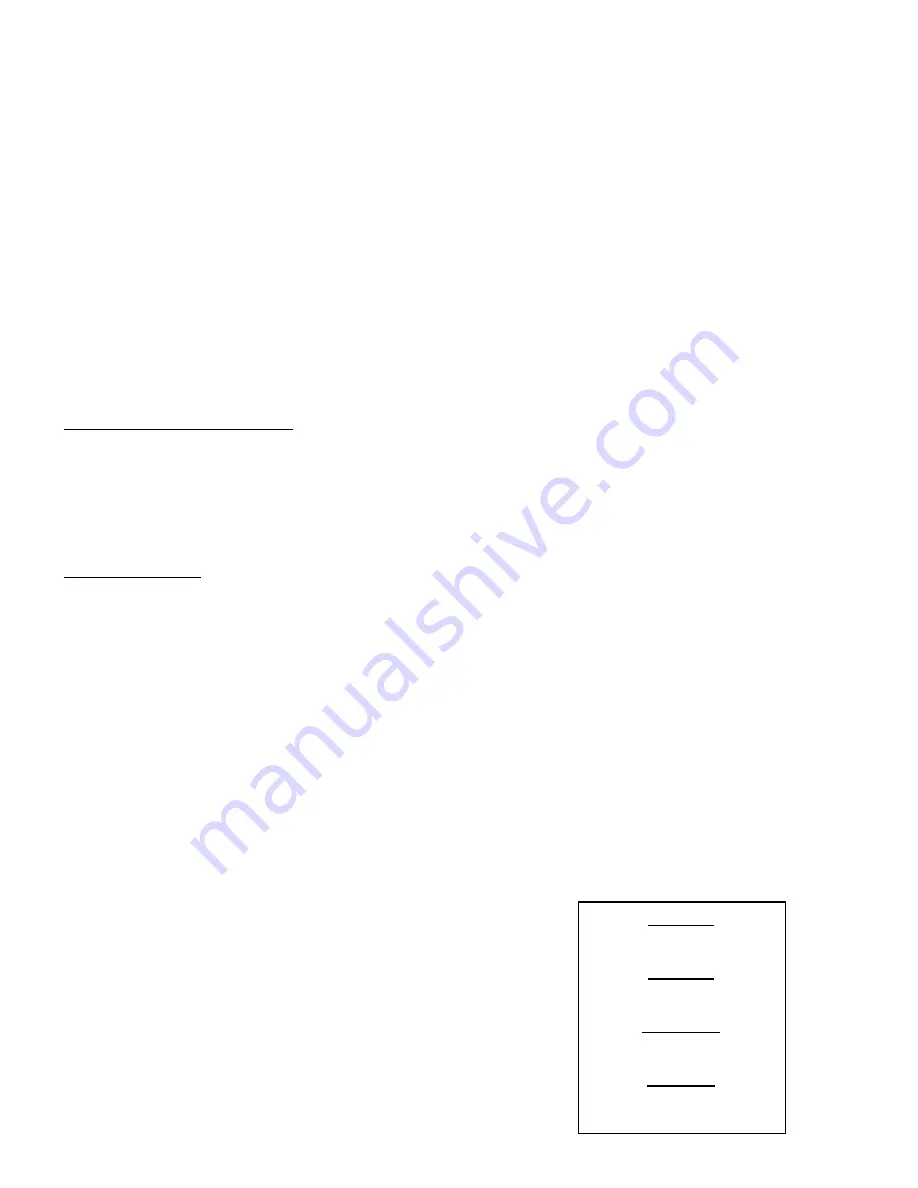

Example:

Application:

Hydronic Heating

Desired System Temperature:

185°F (85°C)

Stage Differentials:

5°F (3°C) per Stage.

Note: The user must first choose which probe is to control the

staging of the unit. The controlling probe will be either the inlet or

tank probe. (If the tank probe is used to regulate loop temperature

in hydronic applications (GB Models), make sure it is located on

the return side of the closed loop.) Use Dip Switch "D" on the

Central Control Board to make this selection. See Figure 14.

Set the stage differentials using the procedure described in the

Procedure for Setting Stage Differential section of the document.

Setting the control as described in the above example (5°F

differentials for each stage) will give the following stage set-points.

Stage One

Off Temperature: 185°F (85°C)

On Temperature: 180°F (82°C)

Stage Two

Off Temperature: 180°F (82°C)

On Temperature: 175°F (79°C)

Stage Three

Off Temperature: 175°F (79°C)

On Temperature: 170°F (77°C)

Stage Four

Off Temperature: 170°F (77°C)

On Temperature: 165°F (74°C)