5

Example: A Genesis boiler is rated at 1,300,000 Btu/hr. input at sea

level. At an altitude of 5,000 (1500m), the prejet orifices will decrease

the input rate by 20% (= 4% x 5) to a new rating of 1,040,000 Btu/hr.

(= 80% x 1,300,000 Btu/hr.) The input reduction is achieved by the

prejet orifices through self-regulation.

FEATURES/CONTROLS

MULTI-STAGE FIRING AND CONTROL SYSTEM

ALL MODELS - The control system consists of three basic

components: 1) Central Control Board 2) Ignition Control Board

and 3) Display Board. The Central Control Board and Ignition

Control Boards are located in the control box and can be accessed

through panels on the left side and top of the unit. The Display

Board is attached to the front jacket panel. The control system is a

multi-stage control capable of managing three or four ignition

stages. Three stage models include the 1000, 1300 and 1500.

Four stage models include the 1850, 2100 and 2500. Every system

will have one Central Control Board, one Display Board and either

three or four Ignition Control Boards depending on the model.

There will be one Ignition Control Board per stage.

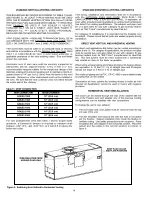

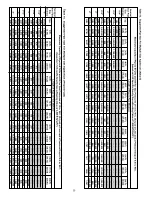

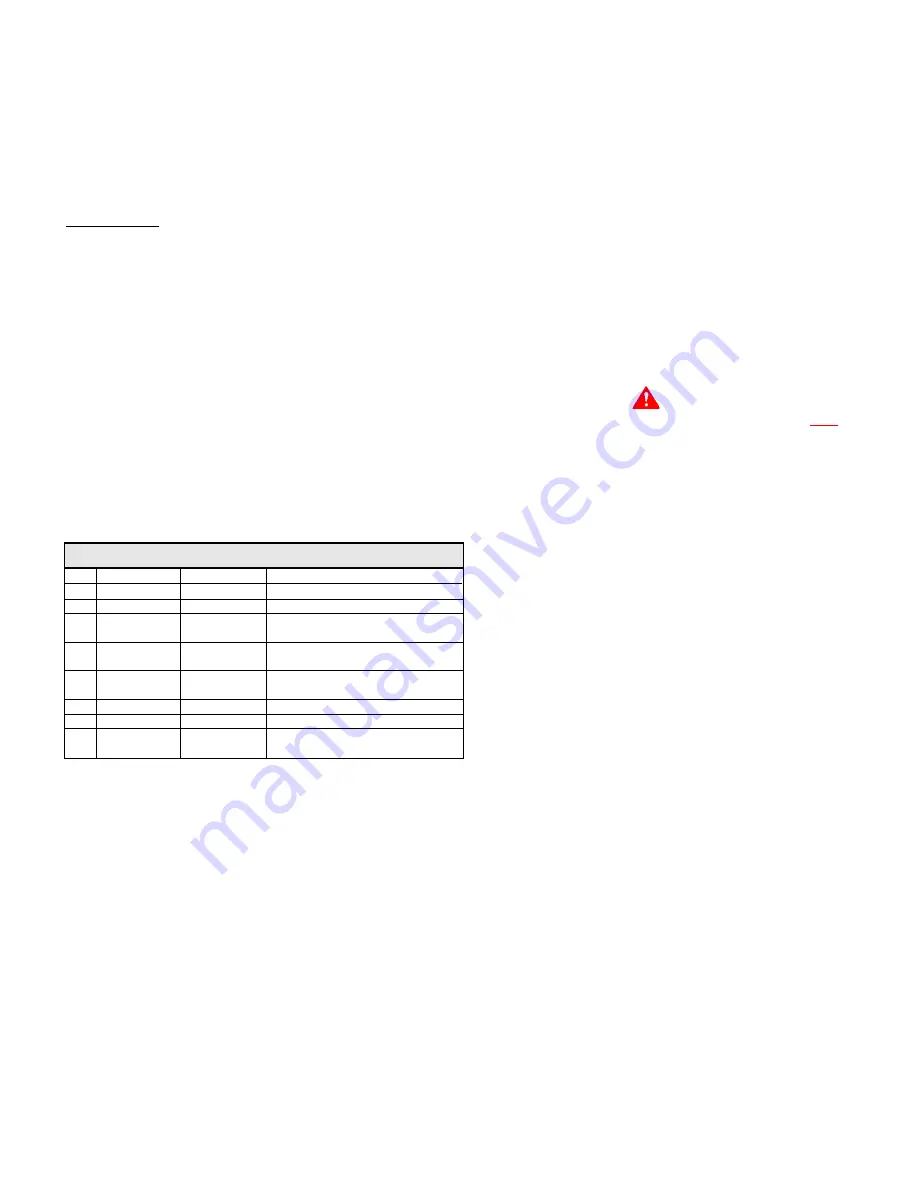

The central control board contains a strip of dip switches which

allow the user to control several system variables. Table 5 shows

a summary of these options.

Make sure the dip switches are in

the appropriate position for the unit's application.

Consult the

Control System section of the manual for more information, see

page 26.

Figure 2. Summary of Dip Switch Options.

DIFFERENTIAL PRESSURE SWITCH

The differential pressure switch ensures that a sufficient differential

exists between the air pressure in the pre-mix chamber and the

inlet of the burner for safe, low NOX combustion. The switch has

two pressure taps marked "+" (positive) and "-" (negative). Silicone

tubing is run from the positive pressure tap of the switch to a tap on

the control panel to measure the air pressure in the pre-mix

chamber. The negative pressure tap measures the pressure taken

at the burner's auxiliary tube. Connections can be seen by removing

the lower front jacket panel. It is important that this panel remain

sealed at all times while the boiler is operating.

This differential pressure switch is normally open and closes when

the combustion blower starts.

BLOCKED FLUE PRESSURE SWITCH

The blocked flue pressure switch ensures that the flue gas vent is

clear. This pressure switch is normally closed and only opens on

the fault conditions.

FLAME SENSOR

The flame sensor acts to prove the flame has carried over from the

ignitor to the right-most burner. If no flame is sensed, the gas

valve(s) will close automatically. If no flame is sensed on three

ignition trials the boiler will lock out. Upon lockout, manually push

the ENTER/RESET button

on the display panel to restart the boiler.

WATER FLOW SWITCH

The Water Flow Switch is installed at the boiler outlet to prevent

burner operation in the event of inadequate water flow through the

boiler. The Water Flow Switch is a single pole, normally open

switch that will close its contacts when increasing water flow rate

is encountered. This switch is factory-set, but may require field

adjustment. The contacts will open when the flow rate drops below

the adjusted setting and the gas valve(s) will close turning off the

gas to the burners.

LIMIT CONTROLS

CAUTION

LIMIT CONTROLS ARE SAFETY DEVICES AND ARE NOT TO BE

USED AS A THERMOSTAT.

The GB/GW models incorporate an outlet water probe consisting

of two limit controls:

1. An adjustable automatic reset limit control, that can be set to

either 210°F (99°C) or 240°F (115°C) depending on the

application.

2. A fixed manual reset limit factory set at 250°F (121°C). If the

manual reset should open due to high temperature the gas

valves will close and the unit will go into lockout.

If lockout occurs, manually push the ENTER/RESET

push-button on the display panel to restart the boiler.

ON/OFF SWITCH

The ON/OFF switch is a single-pole, single-throw rocker switch.

The switch provides 120VAC from the line source to the boiler.

COMBUSTION AIR BLOWER

Provides air for combustion process. The blower settings are

adjustable through the use of the air shutter, however, blowers are

set at the factory and should not need adjustment.

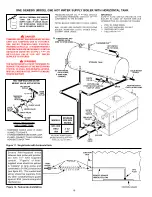

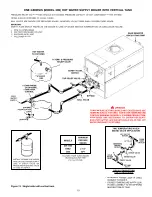

TANK PROBE

FOR HOT WATER SUPPLY SYSTEMS (GW models)

, A tank probe is

supplied with each hot water supply boiler. The inlet water

temperature will default to the tank temperature on the display when

the tank probe is installed.

Note: Tank Probe must be designated as controlling probe using

Dip Switch "D" on Central Control Board before it can be used for

(GW) hot water supply applications.

"Pigtails" of field-supplied wires should be spliced to "pigtails" of

tank probe and connected to terminal block in the 24 volt junction

box. See figure 12 for the tank probe installation. Follow the

instructions for the operation and temperature setting procedures

for the tank probe (see page 29).

FOR HOT WATER HEATING SYSTEMS (GB models)

Due

to the

many various types of systems and operating conditions, a tank

DIP SWITCH CONFIGURATION TABLE

SW1 OFF

ON

SELECTION:

A

3 STAGE

4 STAGE

EITHER 3 OR 4 STAGE SYSTEM

B

3 TRIALS

1 TRIAL

EITHER 3 OR 1

C

NO IRI

IRI

WHETHER SYSTEM IS IRI OR

GAS VALVE

GAS VALVE

STANDARD

D

INLET

TANK

INLET OR TANK AS

CONTROLLING PROBE

E

NO EXTERNAL EXTERNAL

WHETHER EXTERNAL

THERMOSTAT THERMOSTAT

THERMOSTAT IS USED

F

OUTLET 210°F OUTLET 240°F OUTLET MAXIMUM TEMPERATURE

G

190°F

220°F

MAX. SET-POINT TEMPERATURE

H

DEGREES °F

DEGREES °C

EITHER °F OR °C FOR DISPLAYED

TEMPERATURE