16

WATER CONNECTIONS

Water piping must be installed in accordance with the instructions

in this manual and all local plumbing codes having jurisdiction.

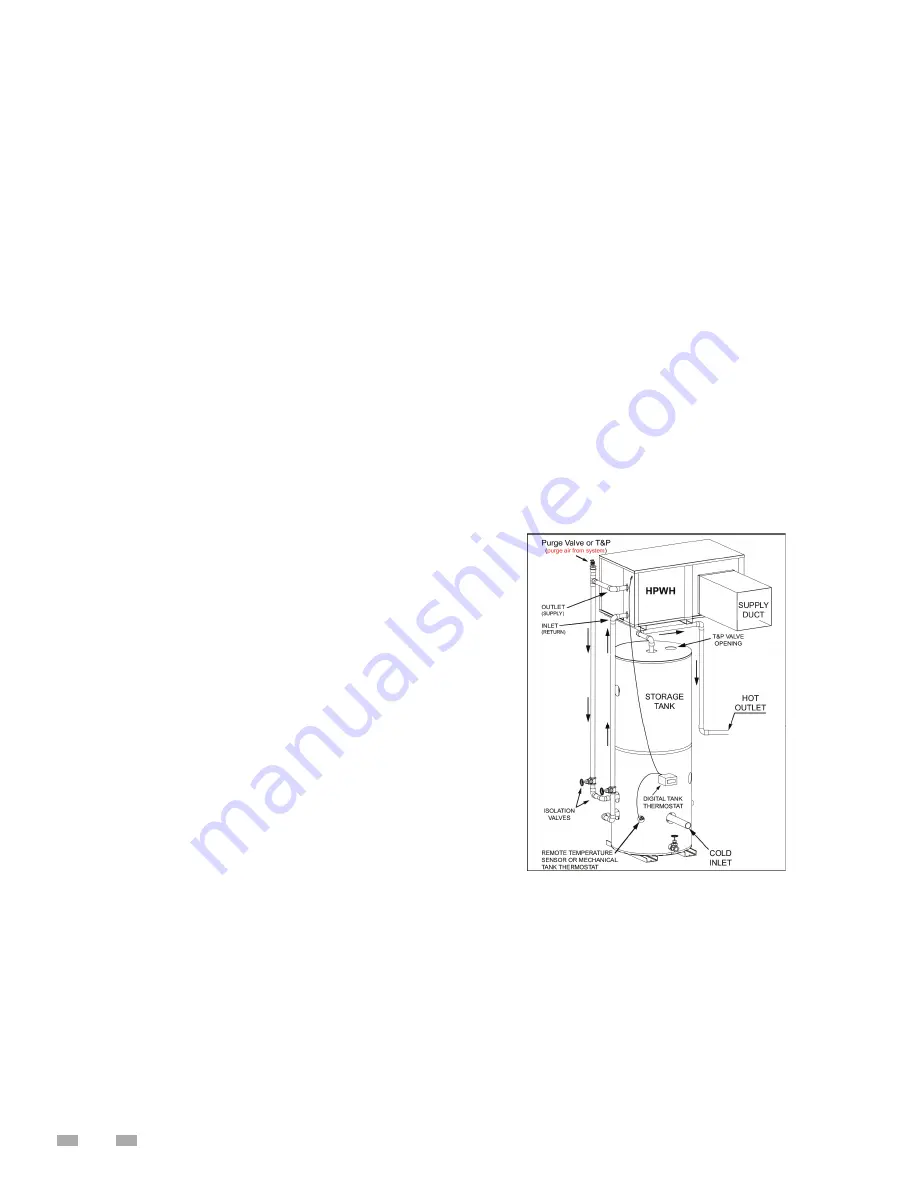

See Figure 7 and Figure 8 and the Piping Diagrams on page 28 as

a reference for these instructions.

INSTALLATION INSTRUCTIONS

1.

This HPWH unit is not designed to supply hot water directly

to hot water fi xtures. The HPWH unit must be installed with a

separate storage tank as shown in the water piping diagrams

in this instruction manual.

2. Water lines installed between the storage tank and the

HPWH unit MUST NOT be less than the water pipe

connection sizes on the unit. See Table 4 on page 12.

3. The HPWH should be plumbed directly to the storage

tank.

4. The cold water supply must be connected directly to the

storage tank at a low connection port on the storage tank

on single tank and two tank preheat piping confi gurations

for optimal effi

ciency. See Figure 7 and Figure 8..

5. The cold water supply MUST NOT be connected the inlet

(entering/return) water line to the HPWH unit.

6. The outlet (supply) water from the HPWH unit should

connect to a middle or lower port on the storage tank.

7.

The inlet (return) water from the HPWH unit should connect

to a port on the storage tank lower than the outlet.

8. A heat trap should be installed between the storage tank

and the backup water heater on two tank preheat systems.

See Piping Diagram on page 28.

9. A T&P valve must be installed in the designated opening

on the storage tank per the tank manufacturer’s requirements.

See Temperature - Pressure Relief Valve on page 13.

10. For optimal performance minimize the equivalent length

of water piping between the HPWH and storage tank.

11. Building hot water recirculation loop should be

connected to the inlet of the backup water heater on

two tank preheat confi gurations or to the storage tank on

single tank confi gurations. The recirculating pump MUST

BE controlled by a fi eld supplied thermostat installed in

the building recirculation return line near the storage

tank or back up heater. The thermostat should stop pump

operation the moment the recirculation line is hot.

12. Use swing-type check valves (not spring-loaded types) on

the water outlet lines of all HPWH units plumbed in parallel

to prevent hot water short-circuiting.

13. Water lines shared by parallel HPWH units must be large

enough to handle combined water fl ows. Flow rates

through the heat pumps and tank(s) must be balanced.

See Table 1 on page 8 for HPWH unit fl ow rates.

14. All components in the hot water supply system must be

adequately sized to meet peak water fl ow requirement

15. When the HPWH unit is installed above the storage tank

install a Tee fi tting at a high point in the outlet water line

leaving the unit. Install a purge valve, or if required by

local code, a T&P valve (temperature and pressure relief )

in a branch of the Tee fi tting that can be used to purge

air from the HPWH unit during start up. See Figure 7 and

Figure 8.

16. DO NOT install a (T&P) relief valve in the outlet line of the

HPWH unit unless required by local code.

17. Dielectric unions should be installed at the inlet and outlet

water lines to the HPWH unit.

18. All HPWH water piping must be insulated.

SINGLE TANK CONFIGURATION

The HPWH must be plumbed to storage tank. The maximum

stored water temperature the HPWH unit can produce in the

storage tank is 150°F (66°C). Figure 7 shows a typical storage

tank piping configuration. Tank ports must be large enough

to handle the peak water fl ow rates through the water heating

system. See Piping Diagrams on page 28 for detailed piping

diagrams.

MULTIPLE TANK PRE HEAT CONFIGURATION

When water temperatures above 150°F (66°C) are required the

HPWH and storage tank are piped in series (upstream) with a

backup water heater. See Water Temperature on page 9. The

backup water heater will raise the temperature of the

preheated water to the fi nal system temperature required.

Figure 8 shows a typical preheat piping confi guration.

FIGURE 7

Summary of Contents for AHPM-270

Page 2: ......

Page 10: ...6 Thermostatic Expansion Valve TXV Condenser Paddle Wheel Flow Sensor Accumulator Receiver...

Page 11: ...7 WATER TO WATER CYCLE...

Page 40: ...36 Service Log Issue Description Date Servicer...

Page 41: ...Service Log Issue Description Date Servicer 37...

Page 42: ...Notes 38...

Page 43: ......

Page 44: ......