TABLE 2

MODEL

VOLTS/PHASE/HZ

COMPRESSOR

BLOWER MOTOR PUMP (230 VAC 1Ø)*

MCA

MFS

RLA

LRA

MCC

FLA

HP

FLA

HP

AWH-35

208-230/1/60

18.60

100.00

29.00

3.60

1/2

0.88

1/8

28

45

AWH-

3

5

208-230/3/60

10.90

77.00

17.00

2.40

1/2

0.88

1/8

17

25

AWH-

3

5

460/3/60

5.40

39.00

8.50

1.20

1/2

0.88

1/8

9

12

AWH-55

208-230/1/60

27.90

175.00

43.50

5.30

3/4

0.88

1/8

42

60

AWH-55

208-230/3/60

19.90

115.00

31.00

3.00

3/4

0.88

1/8

29

45

AWH-55

460/3/60

8.70

63.00

13.50

1.50

3/4

0.88

1/8

13

20

AWH-75

208-230/3/60

24.00

196.00

37.50

3.60

1

0.88

1/8

35

50

AWH-75

460/3/60

11.50

100.00

18.00

1.80

1

0.88

1/8

17

25

AWH-100

208-230/3/60

28.20

225.00

44.00

3.60

1

0.88

1/8

40

60

AWH-100

460/3/60

14.10

114.00

22.00

1.80

1

0.88

1/8

20

30

AWH-115

208-230/3/60

35.30

239.00

55.00

3.60

1

1.00

1/6

49

80

AWH-115

460/3/60

17.90

125.00

28.00

1.80

1

1.00

1/6

25

40

AWH-140

208-230/3/60

48.10

300.00

75.00

4.80

1 1/2

2.50

1/2

68

110

AWH-140

460/3/60

21.80

150.00

34.00

2.40

1 1/2

2.50

1/2

31

50

AWH-170

208-230/3/60

52.60

340.00

82.00

6.20

2

2.50

1/2

75

125

AWH-170

460/3/60

25.60

173.00

40.00

3.10

2

2.50

1/2

37

60

*460 VAC models factory-equipped with step down transformer for 230 VAC pump

Abbreviations:

RLA = Running Load Amps;

LRA = Locked Rotor Amps;

MCC = Maximum Continuous Current;

FLA = Full Load Amps;

MCA = Minimum Circuit Ampacity;

MFS = Maximum Fuse Size

11

UNCONDITIONED SPACE

When installed in an unconditioned space ducting return (inlet)

air from an alternate location may be necessary to access an

adequate or greater source of heat for optimal efficiency. See

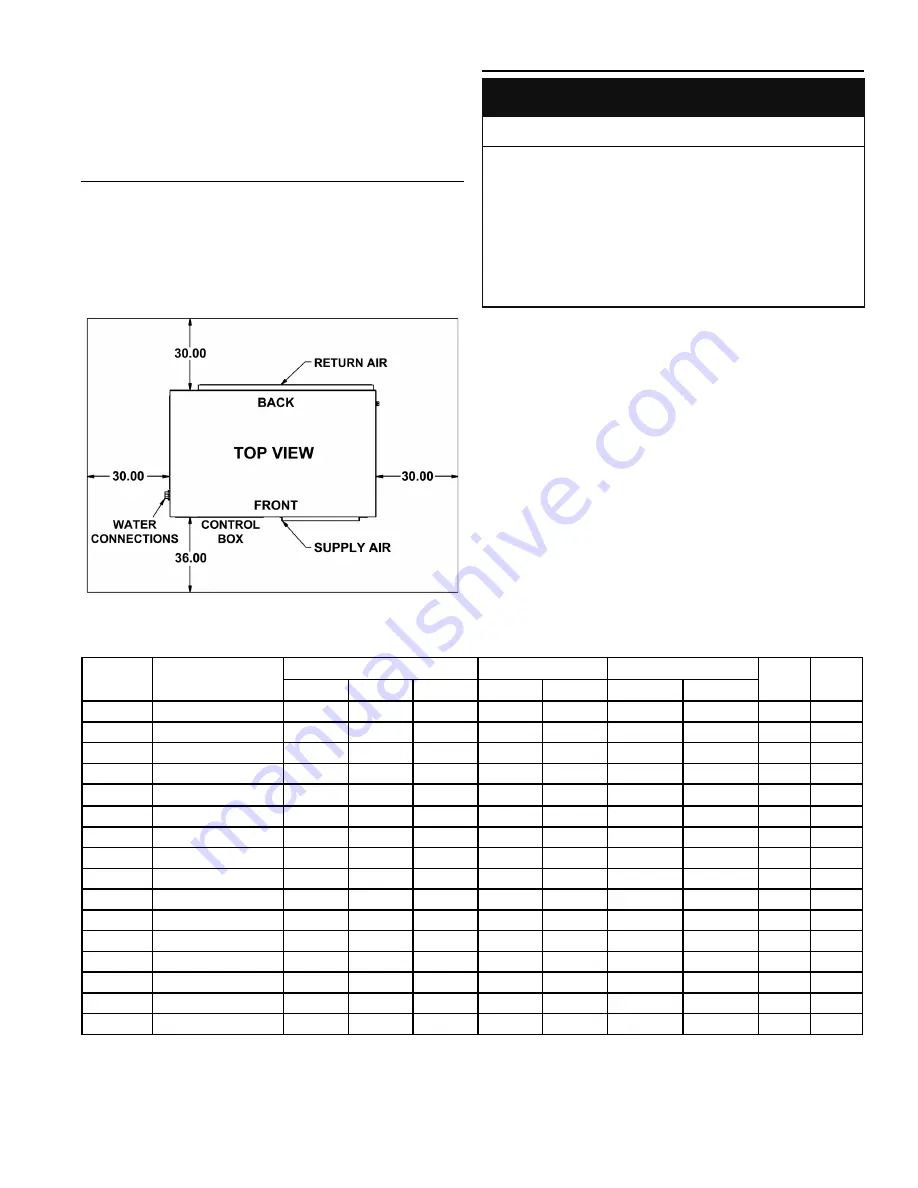

CLEARANCES

To ensure optimal performance a minimum of 30 inches clearance

is required from the back, left and right sides of the HPWH unit

and any wall obstruction. A minimum of 36 inches clearance on

the front of the unit for access to the control box. See Figure 3

When installed on an equipment pad the HPWH must be level

and elevated at least 6” above floor to avoid dust and debris and

permit connection of the condensate line and trap.

Figure 3

ELECTRICAL REQUIREMENTS

CORRECT POWER SUPPLY!

Ensure the power supply at the job site matches the

voltage and phase listed on the HPWH rating label

before connecting power to the HPWH unit.

•

Damage caused to the HPWH as the result of applying

the wrong voltage or phase is not covered under the

limited warranty.

•

Energizing the HPWH with the wrong voltage or phase

will cause permanent damage to the HPWH unit.

•

CAUTION

Ensure the power supply voltage and phase at the job site

matches the power supply ratings listed on the HPWH rating

label BEFORE INSTALLATION BEGINS.

The installation must conform with these instructions and the

local code authority having jurisdiction and the requirements

of the power company. In the absence of local codes, the

installation must comply with the current editions of the National

Electrical Code, ANSI/NFPA 70 or the Canadian Electrical Code

CSA C22.1.

Voltage applied to the HPWH should not vary more than +5% to

-10% of the voltage requirement listed on the HPWH rating label

for satisfactory operation.

VOLTAGE & AMPERAGE RATINGS

Summary of Contents for AWH-35

Page 2: ......

Page 32: ...UNIT WIRING DIAGRAMS FUSE SIZES 208 230 VAC SINGLE PHASE 60 HZ 32...

Page 33: ...UNIT WIRING DIAGRAMS FUSE SIZES 208 230 VAC THREE PHASE 60 HZ AWH 35 AWH 55 and AWH 75 only 33...

Page 34: ...UNIT WIRING DIAGRAMS FUSE SIZES 208 230 VAC THREE PHASE 60 HZ only 34...

Page 35: ...UNIT WIRING DIAGRAMS FUSE SIZES 460 VAC THREE PHASE 60 HZ 35...

Page 36: ...UNIT WIRING DIAGRAMS FUSE SIZES 460 VAC THREE PHASE 60 HZ only 36...