8

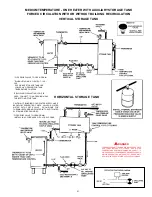

The National Sanitation Foundation also recommends

circulation of 180

0

F (82°C) water. Where this is done, the

circulation should be very gentle so that it does not cause any

unnecessary turbulence inside the water heater. The circulation

should be just enough to provide 180

0

F (82°C) water at the point

of take-off to the dishwashing machine. Adjust flow by means of

the plug cock in the circulating line.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPLY, VENTING, GAS SUPPLY AND ELECTRICAL WORK ARE

REQUIRED.

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

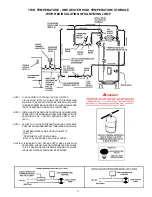

UNCRATING

The heater is shipped with the flue damper already installed.

The wiring conduit runs from the thermostat to the damper drive

cover. Before turning unit on, check to make sure the wiring

conduit is securely plugged into damper drive.

LOCATING THE HEATER

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the stack or

chimney as practicable, with adequate air supply and as

centralized with the piping system as possible.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES

SUCH AS GAS WATER HEATERS IN ROOMS, GARAGES OR

OTHER AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERATED OR REPAIRED. FLAMMABLE VAPORS

ARE HEAVY AND TRAVEL ALONG THE FLOOR AND MAY BE

IGNITED BY THE HEATER’S PILOT OR MAIN BURNER FLAMES

CAUSING FIRE OR EXPLOSION. SOME LOCAL CODES PERMIT

OPERATION OF GAS APPLIANCES IN SUCH AREAS IF THEY

ARE INSTALLED 18” (.50 m). OR MORE ABOVE THE FLOOR.

THIS MAY REDUCE THE RISK IF LOCATION IN SUCH AN AREA

CANNOT BE AVOIDED.

DO NOT INSTALL THIS WATER HEATER DIRECTLY ON A

CARPETED FLOOR. A FIRE HAZARD MAY RESULT.

Instead the

water heater must be placed on a metal or wood panel extending

beyond the full width and depth by at least 3 inches (7.6 cm) in

any direction. If the heater is installed in a carpeted alcove, the

entire floor shall be covered by the panel. Also, see the DRAIN

REQUIREMENTS.

THE HEATER SHALL BE LOCATED OR PROTECTED SO IT IS

NOT SUBJECT TO PHYSICAL DAMAGE BY A MOVING VEHICLE.

WARNING

FLAMMABLE ITEMS,

PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE HEATER. OPEN

CONTAINERS OR FLAMMABLE MATERIAL SHOULD NOT BE

STORED OR USED IN THE SAME ROOM WITH THE HEATER.

THE HEATER MUST NOT BE LOCATED IN AN AREA WHERE IT

WILL BE SUBJECT TO FREEZING.

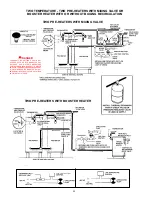

LOCATE IT NEAR A FLOOR DRAIN. THE HEATER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE HEATER

OR CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE

ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

DRAIN PAN SHOULD BE INSTALLED UNDER THE HEATER.

Such pans should be fabricated with sides at least 2" (5 cm)

deep, with length and width at least 2" (5 cm) greater than the

diameter of the heater and must be piped to an adequate drain.

The pan must not restrict combustion air flow.

For appliance installation locations with elevations above 2000

feet (610 m), refer to HIGH ALTITUDE INSTALLATIONS section

of this manual for input reduction procedure.

LEVELING

If the unit is not level, insert the bolts which were used in crating

into the legs to correct this condition.

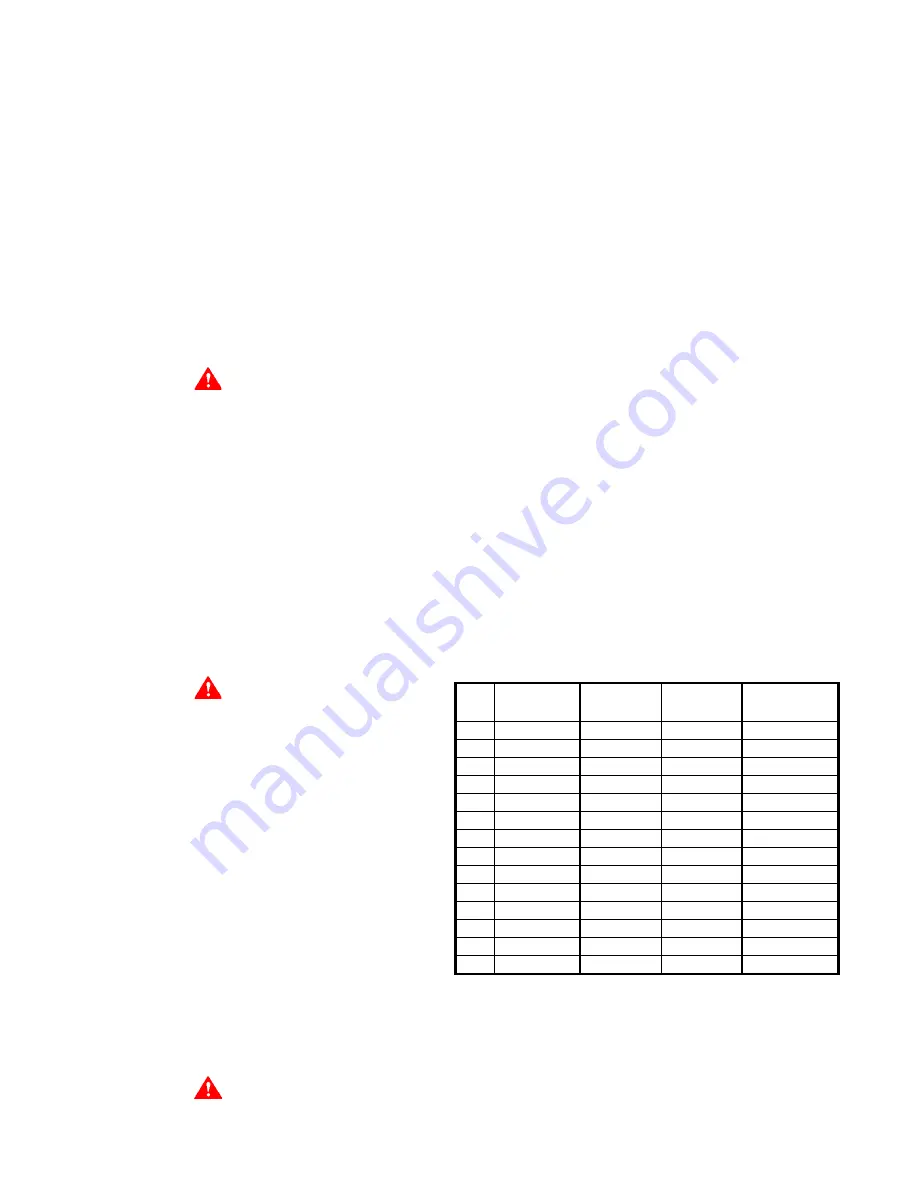

CLEARANCES

These heaters are approved for installation on combustible

flooring in an alcove when the minimum clearance from any

combustion construction are followed as indicated in figure 6

and Table 2.

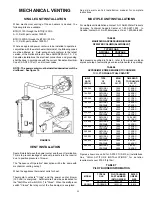

The following units are approved for installation with side, rear

and ceiling clearances as indicated below:

A

B

C

D

(RIGHT SIDE)

(LEFT SIDE)

(BACK)

(CEILING)

120

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

154

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

*180

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

*197

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

198

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

*199

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

200

1” (2.54 cm)

1” (2.54 cm)

1” (2.54 cm)

12” (30.48 cm)

250

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

251

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

275

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

305

2” (5.08 cm)

2” (5.08 cm)

2” (5.08 cm)

12” (30.48 cm)

**365

3” (7.75 cm)

3” (7.75 cm)

3” (7.75 cm)

12” (30.48 cm)

400

3” (7.75 cm)

3” (7.75 cm)

3” (7.75 cm)

12” (30.48 cm)

500

5” (12.7 cm)

5” (12.7 cm)

5” (12.7 cm)

20” (50.80 cm)

* The BTR(C) version has a 2” (5.08cm) to sides and rear.

** The BTR(C) version has a 4” (10.16cm) to sides and rear.

TABLE 2

In all installations the minimum combustible clearances from

any draft hood surface or vent piping shall be 6" (16cm). Vent

piping passing through a combustible wall or ceiling must be a

continuous run (no joints) and retain the 6" (16cm) clearance

unless an approved reducing thimble is used.