14

THE WATER HEATER IS EQUIPPED WITH AN ADJUSTABLE

THERMOSTAT TO CONTROL WATER TEMPERATURE. HOT

WATER AT TEMPERATURES DESIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALDS

RESULTING IN SERIOUS PERSONAL INJURY AND/OR DEATH.

THE TEMPERATURE AT WHICH INJURY OCCURS VARIES WITH

THE PERSON’S AGE AND TIME OF EXPOSURE. THE SLOWER

RESPONSE TIME OF CHILDREN , AGED OR DISABLED PERSONS

INCREASES THE HAZARD TO THEM. NEVER ALLOW SMALL

CHILDREN TO USE A HOT WATER TAP, OR TO DRAW THEIR OWN

BATH WATER. NEVER LEAVE A CHILD OR DISABLED PERSON

UNATTENDED IN A BATHTUB OR SHOWER.

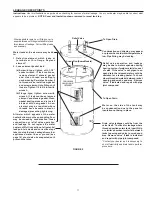

It is recommended that lower water temperatures be used to avoid

the risk of scalding. It is further recommended, in all cases, that the

water temperature thermostats (See Figure 4) be set for the lowest

temperature which satisfies your hot water needs. This will also

provide the most energy efficient operation of the water heater.

Figure 4 shows the approximate time-to-burn relationship for

normal adult skin. The thermostats on your water heater have a

linear relationship between degrees of angular rotation and the

corresponding change in temperature. Thus rotating the temperature

adjustment indicator 30 angular degrees will result in a 10 degree

Fahrenheit change in water temperature.

Water Temperature

°F (°C)

Time for 1st Degree Burn

(Less Severe Burns)

Time for Permanent Burns

2nd & 3rd Degree

(Most Severe Burns)

110 (43)

(normal shower temp.)

116 (47)

(pain threshold)

116 (47)

35 minutes

45 minutes

122 (50)

1 minute

5 minutes

131 (55)

5 seconds

25 seconds

140 (60)

2 seconds

5 seconds

149 (65)

1 second

2 seconds

154 (68)

instantaneous

1 second

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, Sept. 15, 1978)

FIGURE 4

TEMPERATURE ADJUSTMENT

The water heater is supplied with thermostats that may come from

different manufactures and have different temperature indications

as described below.

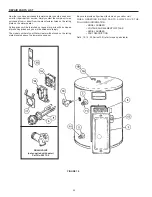

APCOM THERMOSTATS

A-8 Circuit thermostats have three designated set points; LO, MED

and HI. (See Figure 5).The approximate equivalent temperatures for

these three settings are: LO = 140°F (60°C), MED = 160°F (71°C) and

HI = 181°F (83°C). These thermostats are set from the factory at the

LO 140°F (60°C) setting. The over temperature device (ECO high

limit) attached to each thermostat has a manual reset. The C-2 circuit

thermostat is adjustable from approximately 130°F (54°C) to 170°F

(77°C) (See Figure 6). These thermostats are set from the factory at

approximately the 140°F (60°C) setting. The over temperature device

(ECO high limit) attached to each thermostat has a manual reset.

30A 120-250 VAC

22A 277 VAC

12.5A 480-600VAC

125 VA.PT.DTY. 120-480 VAC

MODEL WH10C

MED

40A 120-277 VAC

25A.480-600 VAC

125VA.PT.DTY.

120-480 VAC

APCOM

INC

FIGURE 5

FIGURE 6

THERMODISC THERMOSTATS

A-8 circuit thermostats are adjustable from approximately 120°F

(49°C) (lowest setting) to 181°F (83°C) (highest setting) (See Figure

7). The C-2 circuit thermostat is adjustable from approximately 110°F

(43°C) to 170°F (77°C) (See Figure 8). These thermostats are set

from the factory at approximately the 140°F (60°C) setting. The over

temperature device (ECO high limit) attached to each thermostat

has a manual reset.

L1

L3

L4

T2

T4

L2

T1

THERM O DISC

89T

RESET

RESET

181°F

83°C

60°C

49°C

120°F

140°F

L1

L3

L4

T2

T4

L2

T1

THERM-O-DISC

RESET

170°F

140°F

110°F

RESET

FIGURE 7

FIGURE 8

NOTE: It is not necessary to adjust the upper thermostat for a dual

element unit. However, if it is adjusted above the factory set point

140°F (60°C) it is recommended that it not be set higher than the

lower thermostat setting.

To change the temperature setting:

1. DANGER: Turn off the heater electrical supply. Do not attempt

to adjust thermostat with power on.

2. Open the junction box door (for upper thermostat of dual

element water heater only) and/or remove the (lower) thermostat

access panel. Do not remove the plastic personnel protectors

covering the thermostats. The thermostat is factory pre-set at

140°F (60°C).

3. Using a flat tip screwdriver, rotate the adjusting knob to the

desired temperature setting.

4. Replace the covers and access panels, and turn on heater

electrical supply.

TEMPERATURE REGULATION

Summary of Contents for BURKAY 102 Series

Page 19: ...19 NOTES...