16

16

16

16

16

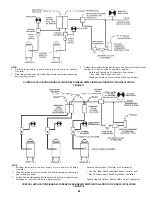

The storage tank temperature and pressure (T & P) relief valve

must comply with the applicable construction provisions of the

Standard for Relief Valves and Automatic Gas Shutoff Devices for

Hot Water Supply Systems, Z21.22 and/or CAN1-4.4. The T & P

valve must be of the automatic reset type and not embody a

single-use type fusible plug, cartridge or linkage.

The T & P relief valve should have a maximum temperature rating

of 100

0

C (210

0

F), a pressure rating NOT exceeding the lowest

rated working pressure of any system component, and a discharge

capacity exceeding the total input of the water boilers supplying

water to the storage tank.

Locate the T & P relief valve (a) in the top of the storage tank, or (b)

in the side of the tank on centerline within the upper 6 inches from

the top of the tank. See figures 20 to 31. Tapping shall be threaded

in accordance with the latest version of the Standard for Pipe

Threads, General Purpose (inch), ANSI/ASME B1.20.1

Mark location with a Class lll label.

See ANSI Z21.10.1, Part 1, MARKING, See CAN/CSA B149.1-00.

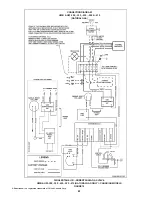

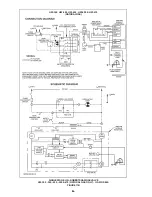

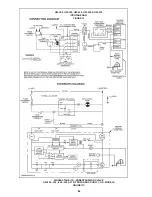

WIRING CONNECTIONS

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

1.

CONVENTIONAL INSTALLATIONS

ALL ELECTRICAL WORK MUST BE INSTALLED IN ACCORDANCE

WITH NATIONAL ELECTRICAL CODE, ANSI/NFPA 70 AND/OR THE

CANADIAN ELECTRICAL CODE, PART 1, CSA C22.1, ELECTRICAL

CODE AND MUST CONFORM TO LOCAL REGULATIONS.

The boiler, when installed, must be electrically bonded to ground

in accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the

National Electrical Code, ANSI/NFPA 70 and/or the Canadian

Electrical Code Part 1, CSA C22.1, Electrical Code.

STRICT ADHERENCE TO PIPING AND WIRING DIAGRAMS IS

REQUIRED TO PREVENT CONSTANT PUMP OPERATION WHEN

SYSTEM TEMPERATURE CONTROL IS SATISFIED. OTHERWISE

THE WARRANTY IS VOID AS STIPULATED IN THE LIMITED

WARRANTY ON THE INSTRUCTIONS MANUAL.

The electrical connections must be made so that the circulator will

operate before the gas valve opens. At no time may the controlling

system allow the burner to fire when there is no water flow through

the boilers.

Refer to the diagrams in fig’s. 10 thru 11C for proper wiring

sequence with conventional single boiler installations.

The THERMAL BALANCER shown is factory included by

A. O. Smith as part no. 98190. This device serves as a pump

shutdown delay switch to balance the rising boiler water

temperature to system temperature before the pump stops.

Overshooting of boiler temperature is prevented and stack loss

after shutdown is negligible.

WARNING

AN ELECTRICAL GROUND IS REQUIRED TO REDUCE RISK OF

ELECTRIC SHOCK OR POSSIBLE ELECTROCUTION. Make the

ground connection to the screw provided in the electrical supply

junction box on the boiler.

IF ANY OF THE ORIGINAL WIRE, AS SUPPLIED WITH THE

APPLIANCE, MUST BE REPLACED, IT MUST BE REPLACED WITH

TYPE 105

0

C WIRE OR ITS EQUIVALENT, EXCEPT FOR THE FLAME

SENSOR AND IGNITION CABLE WHICH ARE 250

0

C AND WIRES

CONNECTED TO THE COIL PROTECTOR WHICH ARE 200

0

C.