16

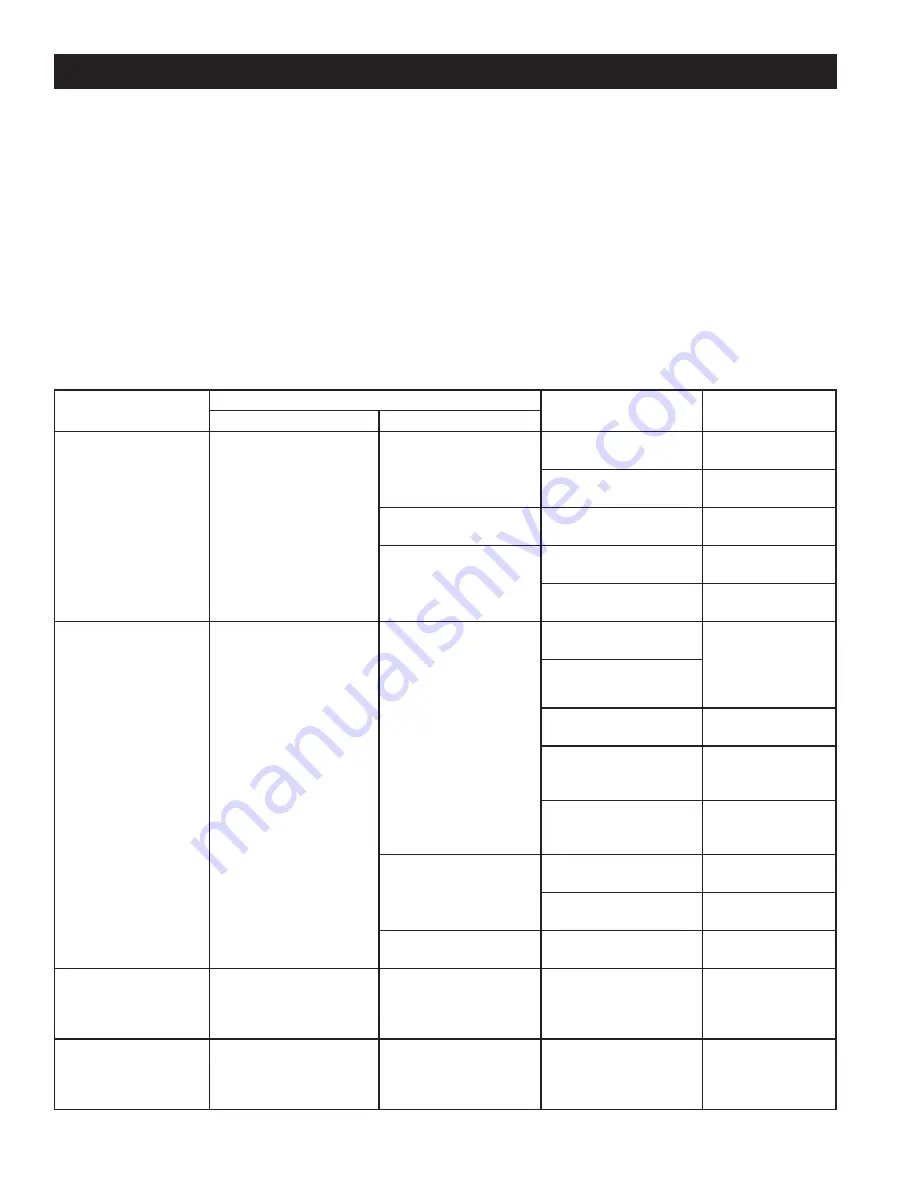

TABLE 3. CER-TEMP 80 RECOVERY SYSTEM CHECKOUT PROCEDURE

Before any extensive troubleshooting, perform the following:

Ensure that:

• Voltage (120 vac) is supplied to the boiler.

• System control (tank temperature control, thermostat,

etc.) is calling for boiler operation (call for heat).

• Other contacts (switches) are closed (relay, low water

cutoff, flow switch, coil protector, pressure switch, etc.).

• Gas supply pressure is within the maximum and minimum

operating ranges listed on the boiler rating plate/label.

• Voltage (24 vac) is supplied by transformer.

• Boiler is wired according to wiring diagram.

Note: Cross wiring the 24 volt circuit of the relay will short the

transformer.

• All wire terminals/connectors are firmly attached to

valves, modules, switches, limit controls, etc.

• For Propane (LP) models only check for possible lockout

condition of the ignition module.

Use this checkout for Cer-Temp 80 Recovery Systems. (For hot water supply application only)

CHECKOUT SEQUENCE

SYSTEM OPERATION

CAUSE

REMEDY

CORRECT

INCORRECT

Set tank temperature

control (thermostat)

20°F (10°C) below tank

water temperature.

Circulating pump and

burner shut off.

With thermal balancer,

pump off delay of

approximately 2 minutes.

Pump and burner remain

on.

Tank temperature control

(thermostat) defective.

Replace.

System wiring is

incorrect.

Correct wiring.

Circulating pump on.

Pump wired for

continuous operation.

Correct wiring.

Burner on.

Gas control valve stuck

or defective.

Correct or replace

valve.

System wiring is

incorrect.

Correct wiring.

Set tank temperature

control (thermostat)

20°F (10°C) above tank

water temperature.

Circulating pump and

burner on.

Circulating pump on.

High limit control set too

low.

Replace. (If

problem proven to

be at this control by

applying jumper to

terminals.)

High limit control

differential too wide.

System wiring is

incorrect.

Correct wiring.

Coil protector switch has

activated.

Remove control

cover, depress

reset button.

Gas control valve or

wiring defective.

Check wiring.

Repair or replace

valve.

Circulating pump and

burner off.

Power off or system

wiring is incorrect.

Check power supply

and wiring.

Tank temperature control

(thermostat) defective.

Replace.

Burner on.

System wiring is

incorrect.

Correct wiring.

Boiler outlet

temperature exceeds

210°F (100°C).

Circulating pump on.

Circulating pump and

burner on.

High limit control

defective, or set too high

(max. should be set at

200°F).

Replace.

Set tank temperature

control (thermostat)

for desired water

temperature.

System maintains desired

water temperature.

TROUBLESHOOTING

Summary of Contents for Burkay HW-300

Page 4: ...4 GENERAL SAFETY...

Page 6: ...6 Figure 1 COMPONENT LOCATIONS CONTROL COMPONENTS...

Page 14: ...14 LIGHTING AND OPERATING INSTRUCTIONS NATURAL AND PROPANE FOR HW300 HW399...

Page 15: ...15 LIGHTING AND OPERATING INSTRUCTIONS NATURAL AND PROPANE WITH I I D FOR HW420 UP...

Page 26: ...26 NOTES...