16

AIR REQUIREMENTS

For safe operation an adequate supply of fresh uncontaminated

air for combustion and ventilation must be provided.

An insufficient supply of air can cause recirculation of combustion

products resulting in contamination that may be hazardous to

life. Such a condition often will result in a yellow, luminous burner

flame, causing sooting of the combustion chamber, burners and

flue tubes and creates a risk of asphyxiation.

Do not install the boiler in a confined space unless an adequate

supply of air for combustion and ventilation is brought in to that

space using the methods described in the Confined Space

section that follows.

Never obstruct the flow of ventilation air. If you have any doubts

or questions at all, call your gas supplier. Failure to provide the

proper amount of combustion air can result in a fire or explosion

and cause property damage, serious bodily injury or death.

UNCONFINED SPACE

An unconfined space is one whose volume is not less than 50

cubic feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the

total input rating of all appliances installed in the space. Rooms

communicating directly with the space, in which the appliances

are installed, through openings not furnished with doors, are

considered a part of the unconfined space.

Makeup air requirements for the operation of exhaust fans,

kitchen ventilation systems, clothes dryers and fireplaces shall

also be considered in determining the adequacy of a space to

provide combustion, ventilation and dilution air.

UNUSUALLY TIGHT CONSTRUCTION

In unconfined spaces in buildings, infiltration may be adequate

to provide air for combustion, ventilation and dilution of flue

gases. However, in buildings of unusually tight construction (for

example, weather stripping, heavily insulated, caulked, vapor

barrier, etc.) additional air must be provided using the methods

described in the Confined Space section that follows.

Breathing Hazard - Carbon Monoxide Gas

Install appliance in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near the boiler.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

CHEMICAL VAPOR CORROSION

Boiler corrosion and component failure can be caused by the

heating and breakdown of airborne chemical vapors. Spray can

propellants, cleaning sol vents, refrigerator and air conditioning

refrig erants, swimming pool chemicals, calcium and sodium

chloride (water softener salt), waxes, and process chemicals

are typical compounds which are potentially corrosive. These

materials are corrosive at very low concentration levels with little

or no odor to reveal their presence.

Products of this sort should not be stored near boiler. Also, air

which is brought in contact with boiler should not contain any

of these chemicals. If necessary, uncontaminated air should be

obtained from remote or outside sources. Failure to observe this

requirement will void warranty.

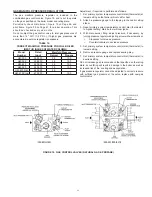

INSTALLATION CLEARANCES

These boilers are approved for installation on combustible

flooring in an alcove with minimum clearance to combustibles of:

HW

300

HW

399

HW

420

HW

520

HW

670

TOP

28" (711.2) 28" (711.2) 24" (609.6) 24" (609.6) 24" (609.6)

SIDES

6" (152.4) 6" (152.4) 24" (609.6) 24" (609.6) 24" (609.6)

REAR

6" (152.4) 6" (152.4) 24" (609.6) 24" (609.6) 24" (609.6)

VENT

6" (152.4) 6" (152.4) 6" (152.4) 6" (152.4) 6" (152.4)

2 inches (51 mm) clearance is allowable from combustible

construction for hot water pipes.

Sufficient area should be provided at the front and rear of the unit for

proper servicing. Clearances of 24 inches (609.4 mm) in the rear and

48 inches (1,219 mm) in the front are required by code. In a utility

room installation, the door shall be wide enough to allow the boiler

to enter or to permit the replacement of another appliance such as

a boiler.

LEVELING

Each unit should be checked after installation to be certain that it

is level prior to starting the unit.

If the unit is not level, obtain and insert shims under the legs of

the unit to correct this condition.

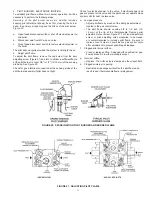

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the requirements of the local code authority having jurisdiction. Good

practice requires that all heavy piping be supported.

TABLE 10. INSTALLATION CLEARANCES