25

Adjustment, if required, is performed as follows:

1. Set primary system temperature control dial (thermostat) at

lowest setting so that boiler will not call for heat.

2. Attach a pressure gauge to the tapping in the control string

elbow.

3. Reset primary system temperature control dial (thermostat)

to highest setting. Main burner will now ignite.

4. With main burner firing, adjust pressure, if necessary, by

turning pressure regulator adjusting screw with a screwdriver.

• Clockwise to increase pressure.

• Counterclockwise to decrease pressure.

5. Set primary system temperature control dial (thermostat) to

lowest setting.

6. Remove pressure gauge and replace sealing plug.

7. Set primary system temperature control dial (thermostat) to

desired setting.

Do not increase gas pressure above that specified on the rating

plate, as overfiring will result in damage to the boiler, as well as

increased risk of fire, sooting and asphyxiation.

If gas pressure regulator cannot be adjusted to correct pressure

with sufficient gas pressure at the valve, replace with new gas

control valve.

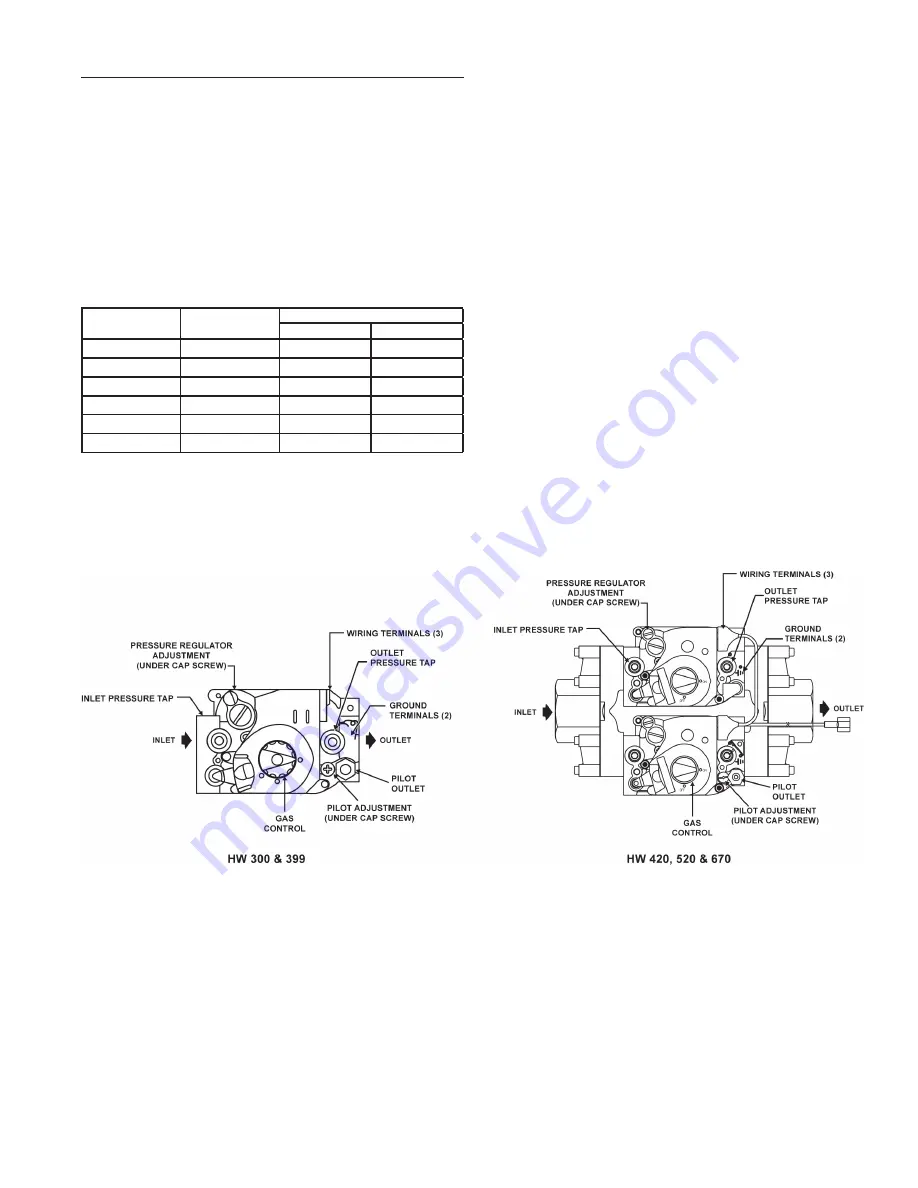

GAS MANIFOLD PRESSURE REGULATORS

The gas manifold pressure regulator is included in the

combination gas control valve, Figure 18, and is set to operate

on the gas specified on the boiler model and rating plate.

Periodically check main burner, Figure 19 on Page 26, and

pilot flame, Figure 20 on Page 27, for proper operation. This

should be checked every six months.

Do not subject the gas control valve to inlet gas pressures of

more than 14" W.C. (1/2 P.S.I.). If higher gas pressures are

encountered, a service regulator is necessary.

Model

Number

Rated

Input

Manifold Pressure

Natural

Propane

HW-300

300,000

3.5

10.0

HW-399

399,000

3.5

10.0

HW-420

420,000

3.5

10.0

HW-520

520,000

3.5

10.0

HW-670 Nat.

660,000

3.5

HW-670 Prop.

670,000

10.0

TABLE 15.

CORRECT MANIFOLD PRESSURE FOR FULL BOILER

INPUT (IN INCHES OF WATER COLUMN)

FIGURE 18. GAS CONTROL VALVES (NATURAL GAS & PROPANE)