42

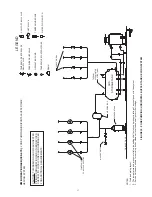

The electrical connections must be made so that the circulating

pump will operate before the gas control valve opens. At no time

may the controlling system allow the burner to fire when there is

no water flow through the boilers.

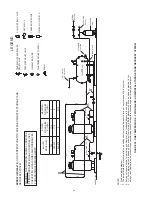

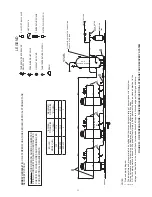

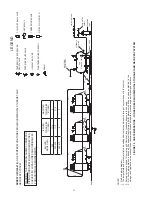

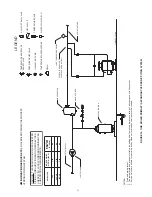

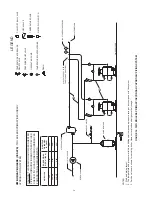

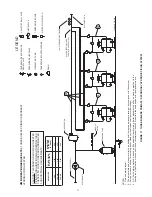

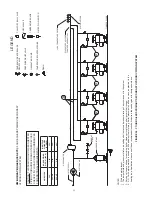

Refer to the diagram in Figure 24 on Pages 43 for proper wiring

sequence with conventional single boiler installations.

The thermal balancer shown is factory included by A. O. Smith.

This device serves as a pump shutdown delay switch to balance

the rising boiler water temperature to system temperature

before the pump stops. Overshooting of boiler temperature is

prevented and stack loss after shutdown is negligible.

If any of the original wire, as supplied with the boiler, must

be replaced, it must be replaced with type 105

0

c wire or its

equivalent, except for the flame sensor and ignition cable

which are 250

0

c and wires connected to the coil protector

which are 200

0

c.

WIRING

WIRING CONNECTIONS

CONVENTIONAL INSTALLATIONS

All electrical work must be installed in accordance with current

editions National Electrical Code, ANSI/NFPA 70 and/or the

Canadian Electrical Code, PART 1, CSA C22.1, Electrical Code

and must conform to local regulations.

The boiler, when installed, must be electrically bonded to ground

in accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the

current editions National Electrical Code, ANSI/NFPA 70 and/

or the Canadian Electrical Code Part 1, CSA C22.1, Electrical

Code.

Strict adherence to piping and wiring diagrams is required to

prevent constant pump operation when system temperature

control is satisfied. Otherwise the warranty is void as stipulated

in the limited warranty on the instructions manual.