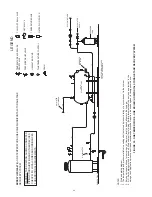

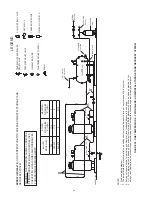

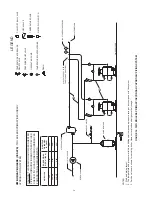

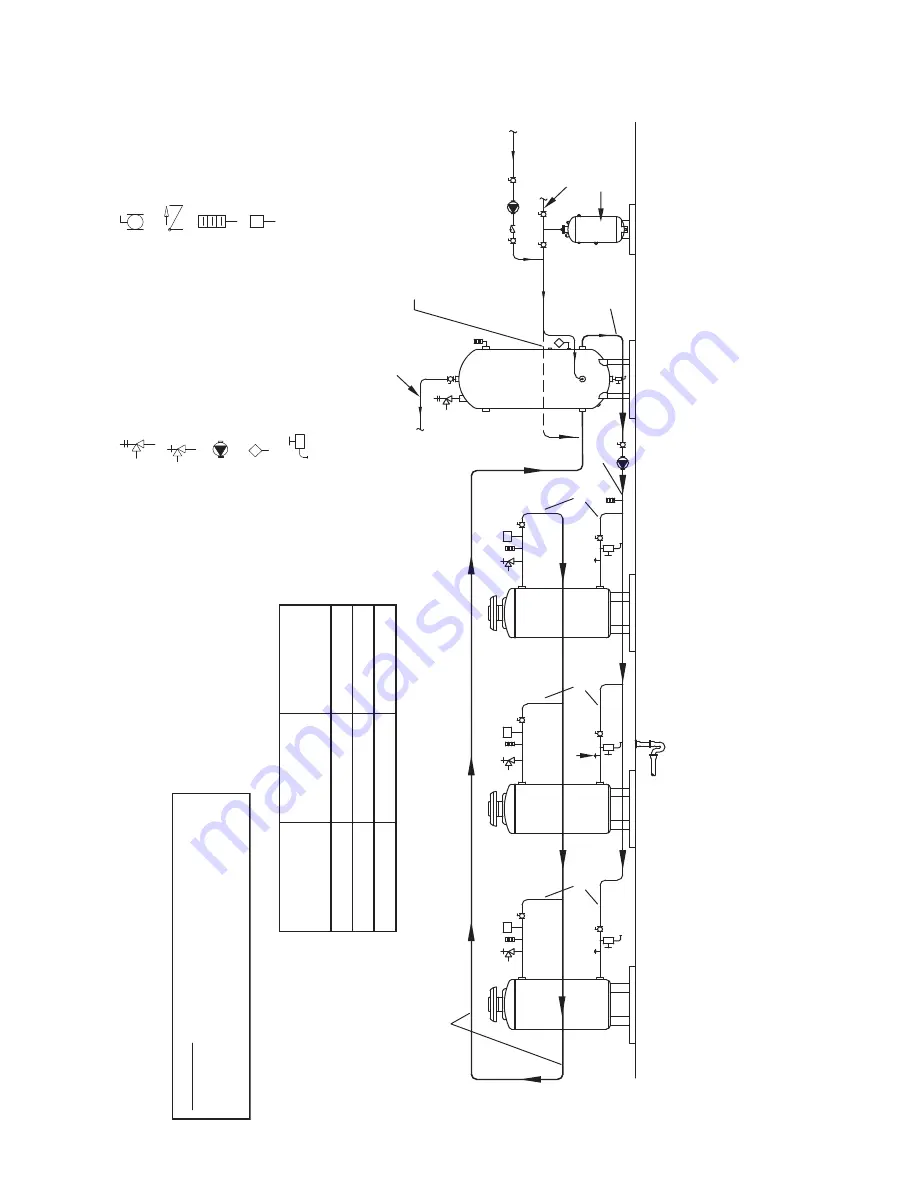

51

N

OTES

:

1.

Pre

ferred

piping

diagram

.

2.

The

tempera

ture

and

pressure

relie

f valve

se

tting

shall

no

t exceed

pressure

ra

ting

o

f any

componen

t in

the

sys

tem

.

3.

Service

valves

are

shown

for

s

ervicing

uni

t.

Howeve

r,

local

codes

shall

govern

their

usage

.

4.

A. O. S

mi

th

piping

me

thod

is

based

on

50

equivalen

t f

ee

t o

f piping

. B

oiler

placemen

t shall

be

as

close

as

prac

tical

to

th

e

st

orage

tank

. A

ppli

ca

tions

in

ex

cess

o

f t

hese

recommenda

tions

shall

require

a

licensed

engineer

for

design

assis

tance

.

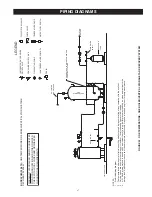

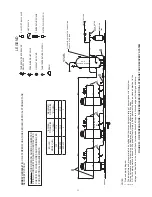

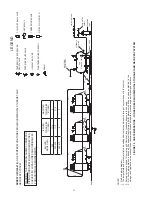

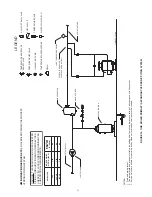

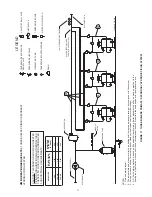

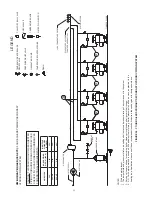

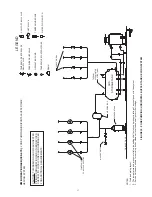

BURK

AY

HW(300-670) -

ONE

TEMPER

ATURE-THREE BOILER/VE

RTICA

L S

TORAGE

T

ANK

RECOVE

RY

SYSTEM

LEGEND

TEMPER

ATURE & PRESSURE

RELIEF

VA

LVE

PRESSURE RELIEF

VA

LVE

CIRCUL

ATING PUMP

TANK

T

EM

PER

ATURE CONTR

O

L

DRAIN

FUL

L PO

RT

BAL

L

VA

LVE

TEMPER

ATURE GAGE

W

ATER FLOW SWITCH

CHECK

VA

LVE

W

ARNING:

THIS DR

AWING SHOWS SUGGESTED

PIPING CONFIGUR

AT

ION

AND OTHER DEVICES;

CHECK WITH LOCA

L CODES

AND ORDINANCES

FOR

ADDITIONA

L REQUIREMENTS.

EXPANSION TANK

COLD WATER SUPPLY

AOS

STORAGE TANK

ALTERNATE COLD WATER CONNECTION FOR OLD STYLE TANK

HOT WATER TO FIXTURES

SYSTEM RETURN

DE-LIMING TEE

FINISHED FLOOR

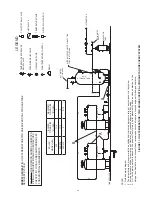

B

A

B

A

A

B

BOILER

MODE

L (HW)

BOILER

PIPING SIZE “A” (INCH)

MANIFOLD PIPING SIZE “B” (INCH)

30

0

1 1/

4

2

399-42

0

1 1/

2

2 1/2

520-67

0

2

3

FIGURE

33.

ONE TEMPERA

TURE - THREE BOILERS/ VERTICAL

ST

ORAGE T

ANK RECOVER

Y SYSTEM