18

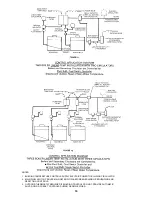

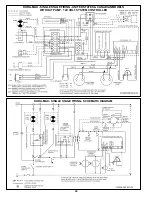

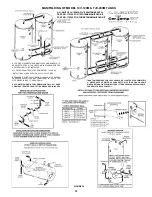

generator type boilers establish temperature rises. The deciding

factor in choice of boiler temperature rise relates to the boiler inlet

temperature. Boiler outlet, minus system temperature drop, is

boiler inlet temperature. THE BOILER TEMPERATURE RISE

SHOULD NOT RAISE THE OUTLET TEMPERATURE UP TO THE

MAXIMUM 250°F (115°C) SETTING OF THE LIMIT CONTROL.

If inlet temperature (plus temperature rise) of any boiler on the

group exceeds 240°F (115°C), that boiler and all downstream

boilers will shut down (cycle on and off).

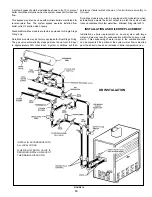

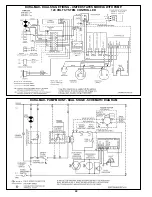

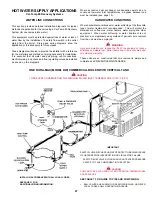

B. Commercial Boiler Replacements

Application of LINEAR-TEMP to a commercial boiler replacement

with an old multiple pump installation is an excellent way to

modernize the system. The A. O. Smith boiler(s) should be

installed on a pipe loop with a separate circulating pump. Use

table 7 to determine pipe sizes and operating ranges.

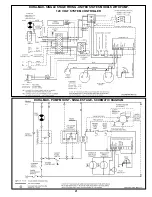

The following illustration shows how the system headers should

be connected to pipe loop that is installed with the replacement

boiler(s). Make-up water connections, and accessories are not

shown.

Supply and return headers of the old system should be connected

to the boiler loop with a pair of tees set close together. The boiler

loop pump and the boiler(s) should be wired to operate only when

any of the system pumps are in operation. The number of zone

pumps that may be in operation at any particular time will take

their required flow rate out from the first tee in the boiler piping.

This water will be circulated through the proper branches from the

supply header to the zones calling for heat. The water will be brought

back to the return header and then into the second tee in the boiler

pipe loop. There will be no conflict between the boiler pump and

the zone pumps when the two tees in the boiler loop are placed

close together.

Normal use of flow control valves is required to prevent cross

circulation of zones as with any multiple pump system.

Large systems with multiple boilers should include main water

temperature controls (with or without outdoor reset) to sequence

the boiler on and off, in relation to the load on the system.

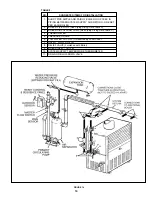

Pressure drop includes the loss through 40' (12 m) of pipe and normal fittings.

Water Category

Grain Hardness per Gal.

Soft

1 through 7.5

Normal

7.6 through 17

Hard

Over 17

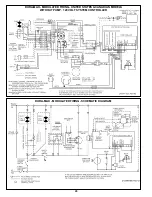

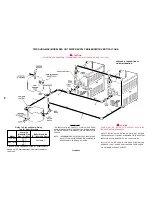

Taco pumps shown. Equivalent Armstrong, Bell & Gossett or Grundfos acceptable.

Always ensure adequate support for pump and piping.

TABLE 7, DuraMax Pump Performance Requirements

Water

Pipe Size Taco Circulator

Category

F

C

GPM LPM

ft

M

Sched. 40

Models

Soft

35

19.4

34

127

3.7

1.1

2"

#0012 (1/7 HP)

Normal

25

13.9

47

178

6.2

1.9

2"

#120 (1/6 HP)

Hard

18

10.0

65

248

12.6

3.8

2"

#1935 (1/3 HP)

Hard

18

10.0

65

248

7.4

2.3

2 1/2"

#121 (1/4 HP)

Soft

35

19.4

39

149

5.9

1.8

2"

#0012 (1/7 HP)

Normal

25

13.9

55

208

8.9

2.7

2"

#120 (1/6 HP)

Hard

18

10.0

76

289

15.1

4.6

2"

#1935 (1/3 HP)

Hard

18

10.0

76

289

10.2

3.1

2 1/2"

#1935 (1/3 HP)

Soft

35

19.4

45

170

6.6

2.0

2"

#0012 (1/7 HP)

Normal

25

13.9

63

238

12.1

3.7

2"

#1935 (1/3 HP)

Normal

25

13.9

63

238

7.6

2.3

2 1/2"

#121 (1/4 HP)

Hard

18

10.0

87

330

12.9

3.9

2 1/2"

#1935 (1/2 HP)

Soft

35

19.4

51

193

7.0

2.1

2"

#120 (1/6 HP)

Normal

25

13.9

72

271

13.1

4.0

2"

#1935 (1/3 HP)

Normal

25

13.9

72

271

7.1

2.2

2 1/2"

#121 (1/4 HP)

Hard

19

10.6

94

356

11.3

3.4

2 1/2"

#1935 (1/2 HP)

Soft

35

19.4

57

217

4.7

1.4

2 1/2"

#120 (1/6 HP)

Normal

25

13.9

80

303

8.8

2.7

2 1/2"

#121 (1/4 HP)

Hard

19

10.6

105

399

13.4

4.1

2 1/2"

#1935 (1/2 HP)

Soft

35

19.4

64

242

6.0

1.8

2 1/2"

#121 (1/4 HP)

Normal

25

13.9

89

339

10.5

3.2

2 1/2"

#1935 (1/3 HP)

Hard

18

10.0

124

470

18.9

5.8

2 1/2"

#1935 (3/4 HP)

Soft

35

19.4

68

259

6.3

1.9

2 1/2"

#121 (1/4 HP)

Normal

25

13.9

96

362

12.7

3.9

2 1/2"

#1935 (1/2 HP)

Hard

18

10.0

133

503

20.5

6.2

2 1/2"

#1935 (3/4 HP)

Hard

18

10.0

133

503

12.2

3.7

3"

#133 (3/4 HP)

Soft

35

19.4

74

281

8.0

2.4

2 1/2"

#121 (1/4 HP)

Normal

25

13.9

104

394

13.6

4.1

2 1/2"

#1935 (1/2 HP)

Hard

20

11.1

130

492

20.7

6.3

2 1/2"

#1935 (3/4 HP)

Hard

20

11.1

130

492

12.4

3.8

3"

#133 (3/4 HP)

Soft

38

21.1

77

291

8.2

2.5

2 1/2"

#121 (1/4 HP)

Normal

28

15.6

104

395

13.8

4.2

2 1/2"

#1935 (1/2 HP)

Hard

22

12.2

133

503

20.9

6.4

2 1/2"

#1935 (3/4 HP)

Hard

22

12.2

133

503

12.6

3.8

3"

#133 (3/4 HP)

* - Head loss includes the loss through 40 feet (12 m) of pipe and normal fittings.

Model

Temp Rise Flow Rate

HdLoss*

DW-720

DW-840

DW-960

DW-1080

DW-1810

DW-1210

DW-1350

DW-1480

DW-1610