7

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS BOILER REQUIRES

ABILITY EQUIVALENT TO THAT OF A LICENSED TRADESMAN

IN THE FIELD INVOLVED. PLUMBING, AIR SUPPLY, VENTING,

GAS SUPPLY AND ELECTRICAL WORK ARE REQUIRED.

WARNING

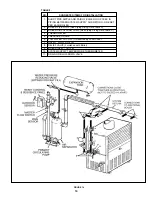

THE INLET/OUTLET WATER MANIFOLD ON YOUR A. O. SMITH

UNIT INCORPORATES AN "O RING" WATER SEAL ASSEMBLY.

THE MANIFOLD IS NOT DESIGNED TO SUPPORT THE WEIGHT

OF THE WATER PIPING SYSTEM. AS ON ALL BOILER

INSTALLATIONS, SPECIAL CARE MUST BE TAKEN TO ENSURE

PROPER SUPPORT.

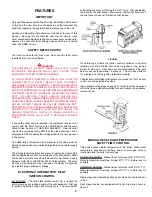

LOCATION

When installing the boiler, consideration must be given to proper

location. Location selected should be as close to the stack or

chimney as practical with adequate air supply and as centralized

with the piping system as possible. This location should also be

such that the gas ignition system components are protected from

water (dripping, spraying, etc.) during appliance operation and

service [circulator replacement, control replacement, etc.].

THE BOILER MUST NOT BE INSTALLED ON CARPETING.

THE BOILER SHOULD NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

LOCATE IT NEAR A FLOOR DRAIN. THE BOILER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE BOILER

OR CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE

ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

DRAIN PAN SHOULD BE INSTALLED UNDER THE BOILER. Such

pans should be fabricated with sides at least 2-1/2" (64 mm) deep,

with length and width at least 2" (51 mm) greater than the

dimensions of the boiler and must be piped to an adequate drain.

The pan must not restrict combustion air flow.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES IN

ROOMS OR AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERATED OR REPAIRED. FLAMMABLE VAPORS

ARE HEAVY AND TRAVEL ALONG THE FLOOR AND MAY BE

IGNITED BY THE IGNITER OR MAIN BURNER FLAMES

CAUSING FIRE OR EXPLOSION. SOME LOCAL CODES PERMIT

OPERATION OF GAS APPLIANCES IF INSTALLED 18 INCHES

OR MORE ABOVE THE FLOOR. THIS MAY REDUCE THE RISK

IF LOCATION IN SUCH AN AREA CANNOT BE AVOIDED.

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE BOILER.

OPEN CONTAINERS OF FLAMMABLE MATERIAL SHOULD NOT

BE STORED OR USED IN THE SAME ROOM WITH THE BOILER.

If the boiler is installed above the level of heating system terminal

units, a low water cutoff device must be installed in the boiler outlet

at the time of installation.

For installation locations with elevations above 2,000 feet (610 M),

refer to the HIGH ALTITUDE INSTALLATIONS section of this

manual for input reduction procedure.

CHEMICAL VAPOR CORROSION

Heat exchanger corrosion and component failure can be caused

by the heating and breakdown of airborne chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air conditioning

refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes, and process chemicals are typical compounds

which are corrosive. These materials are corrosive at very low

concentration levels with little or no odor to reveal their presence.

Products of this sort should not be stored near the boiler. Also, air

which is brought in contact with the water boiler should not contain

any of these chemicals. If necessary, uncontaminated air should

be obtained from remote or outside sources.

AIR REQUIREMENTS

WARNING

FOR SAFE OPERATION, AN AMPLE SUPPLY OF AIR MUST BE

PROVIDED FOR PROPER COMBUSTION AND VENTILATION

IN ACCORDANCE WITH SECTION 5.3, AIR FOR COMBUSTION

AND VENTILATION, OF THE NATIONAL FUEL GAS CODE, ANSI

Z223.1 OR 7.2, 7.3 OR 7.4 OF CAN/CSA B149.1-00,

INSTALLATION CODES, OR APPLICABLE PROVISIONS OF THE

LOCAL BUILDING CODES. AN INSUFFICIENT SUPPLY OF AIR

MAY RESULT IN A YELLOW, LUMINOUS BURNER FLAME,

CARBONING OR SOOTING OF THE FINNED HEAT

EXCHANGER, OR CREATE A RISK OF ASPHYXIATION. DO NOT

OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION

AIR.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion, and

draft hood dilution.

If the unconfined space is within a building of tight construction

(buildings using the following construction; weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation, and draft hood dilution must be obtained from outdoors

or spaces freely communicating with the outdoors. The installation

instructions for confined spaces in tightly constructed buildings must

be followed to ensure adequate air supply.

CONFINED SPACE

(a) U. S. INSTALLATIONS

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN OR

WITHIN 12 INCHES (30 CM) OF THE ENCLOSURE TOP AND

ONE IN OR WITHIN 12 INCHES (30 CM) OF THE ENCLOSURE

BOTTOM. Each opening shall have a free area of at least one

square inch per 1000 Btuh (2,208 mm

2

of per kw) of the total input

of all appliances in the enclosure, but not less than 100 square

inches (645 cm

2

).