8

If the confined space is within a building of tight construction, air for

combustion, ventilation, and draft hood dilution must be obtained

from outdoors. When directly communicating with the outdoors or

communicating with the outdoors through vertical ducts, two

permanent openings, located in the aforementioned manner, shall

be provided. Each opening shall have a free area of not less than

one square inch per 4000 Btu/hr (551 mm

2

per kw) of the total

input of all appliances in the enclosure. If horizontal ducts are

used, each opening shall have a free area of not less than one

square inch per 2000 Btu/hr (1101 mm

2

per kw)

of the total input of

all appliances in the enclosure.

(B) CANADIAN INSTALLATIONS

Ventilation of the space occupied by the boiler(s) shall be provided

by an opening for ventilation air at the highest practical point

communicating with outdoors. The total cross- sectional area shall

be at least 10% of the area of the combustion air opening but in no

case shall the cross-sectional area be less than 10 square inches

(6500 mm²).

In addition to the above, there shall be permanent air supply

opening(s) having a cross-sectional area of not less than 1 square

inch per 7,000 BTUH (315 mm²/kw) up to and including 1,000,000

BTUH plus 1 square inch per 14,000 BTU (158 mm

2

/kw) in excess

of 1,000,000 BTUH. This opening(s) shall be located at, or ducted

to, a point neither more than 18" (450 mm) nor less than 6 inches

(150 mm) above the floor level.

Where power vented equipment is used in the same room as the

boiler, sufficient air openings must be supplied.

UNDERSIZED OPENINGS MAY RESULT IN INSUFFICIENT AIR

FOR COMBUSTION.

Where an exhaust fan is installed in the same room with a boiler,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN

INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT WITH AN INCREASED

RISK OF ASPHYXIATION.

VENTING THE BOILER

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING THE

BOILER MUST BE FOLLOWED TO AVOID CHOKED

COMBUSTION OR RECIRCULATION OF FLUE GASES. SUCH

CONDITIONS CAUSE SOOTING OR RISKS OF FIRE AND

ASPHYXIATION.

SINGLE WALL OR TYPE B VENTING MAY BE USED WITH

THESE BOILERS. ALL LOCAL UTILITY, STATE/ PROVINCIAL,

REGULATIONS ON VENTING MUST BE FOLLOWED.

VENT SIZING, INSTALLATION AND TERMINATION SHALL BE

IN ACCORDANCE WITH PART 7, VENTING OF EQUIPMENT,

OF THE NATIONAL FUEL GAS CODE, ANSI Z223.1, OR SECTION

7, VENTING SYSTEMS AND AIR SUPPLY FOR APPLIANCES,

OF THE CAN/CSA B149, INSTALLATION CODES, OR

APPLICABLE PROVISIONS OF THE LOCAL BUILDING CODES.

1.

DRAFT HOOD

The integral draft hood, louvers or cabinetry must not be altered.

Provision must be made if the boiler is installed in confined space

or a small boiler room to accommodate draft hood spillage and

avoid risks described above. The upper air opening called for in

the AIR REQUIREMENTS section of this manual is for this purpose.

2.

VENT CONNECTION

The minimum distance from adjacent public walkways, adjacent

buildings, openable windows and building openings shall not be

less than those values specified in the National Fuel Gas Code,

ANSI Z223.1 and/or CAN/CSA B149.1-00, Installation Codes:

Stack or chimney must be a minimum height of 12" (305 mm)

above the annual snow fall to prevent blockage.

Building materials must not come in contact with combustion

products from stack or chimney, due to the degrading properties of

flue products.

Materials may be protected from flue products by use of metal or

copper sheeting.

Flue products must have a minimum clearance of 4 feet (1.22 m)

horizontally from, and in no case above or below, unless a 4-foot

(1.22 m) horizontal distance is maintained, from electric meters,

gas meters, regulators and relief equipment.

The Canadian B149.1-00, Installation Code specifies a 6 foot

horizontal vent terminal clearance to gas and electric meters and

relief devices (this clearance is specified as 4 feet in the U.S. under

the National Fuel Gas Code, ANSI/Z223.1). Therefore instruction

provision 1.34.1-b19(d), which specifies compliance with the 4 foot

clearance, as applies in the U.S. only, and the B149.1-00 Installation

Code applies in Canada.

Vent connections must be made to an adequate stack or chimney

and shall be in accordance with Part 7, Venting of Equipment, of

the National Fuel Gas Code, ANSI Z223.1, or Section 7, Venting

Systems and Air Supply for Appliances, of the CAN/CSA-B149.1-

00, Installation Codes, or applicable provisions of the local building

codes. Size and install proper size vent pipe. Do not reduce pipe

size to less than that of the draft hood outlet unless permitted by

local code.

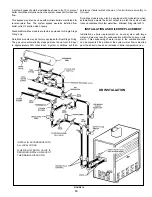

Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 4 feet [1.2 m]),

noncombustible hangers suitable for the weight and design of the

materials employed to prevent sagging and to maintain a minimum

upward slope of 1/4" per foot (21mm/m) from the boiler to the vent

terminals. Dampers or other obstructions must not be installed in

the vent. Be sure that the vent connector does not extend beyond

the inside wall of the chimney.

Where a continuous or intermittent back draft is found to exist the

cause must be determined and corrected. A special vent cap may

be required. If the back draft cannot be corrected by the normal

methods or if a suitable draft cannot be obtained, a blower type

flue gas exhauster may be employed to ensure proper venting and

correct combustion (where permitted by local code). Contact your

A. O. Smith dealer for power vent instructions.