Installation and Service Manual Epsilon-Series

33

12.2 Check O

2

The O

2

percentage is set by the factory. It has to be checked during inspection,

maintenance and faults.

This can be checked by means of the following procedure:

- Remove the black cover of the gas valve by unscrewing the sealed screw.

- Put the boiler into operation and take care that it can deliver its heat;

- Press the MODE-key for 5 seconds.

- The diplay will show COdE followed by an arbitrary number;

- Select by means of the + or the - key the code C123;

- Press the Store-key to confirm the code (code blinks 1 x);

- Press the MODE-key until SERV is shown;

- Press the STEP-key once until 1 is shown;

alternately 1 and OFF will be shown.

- Calibrate the O

2

meter ;

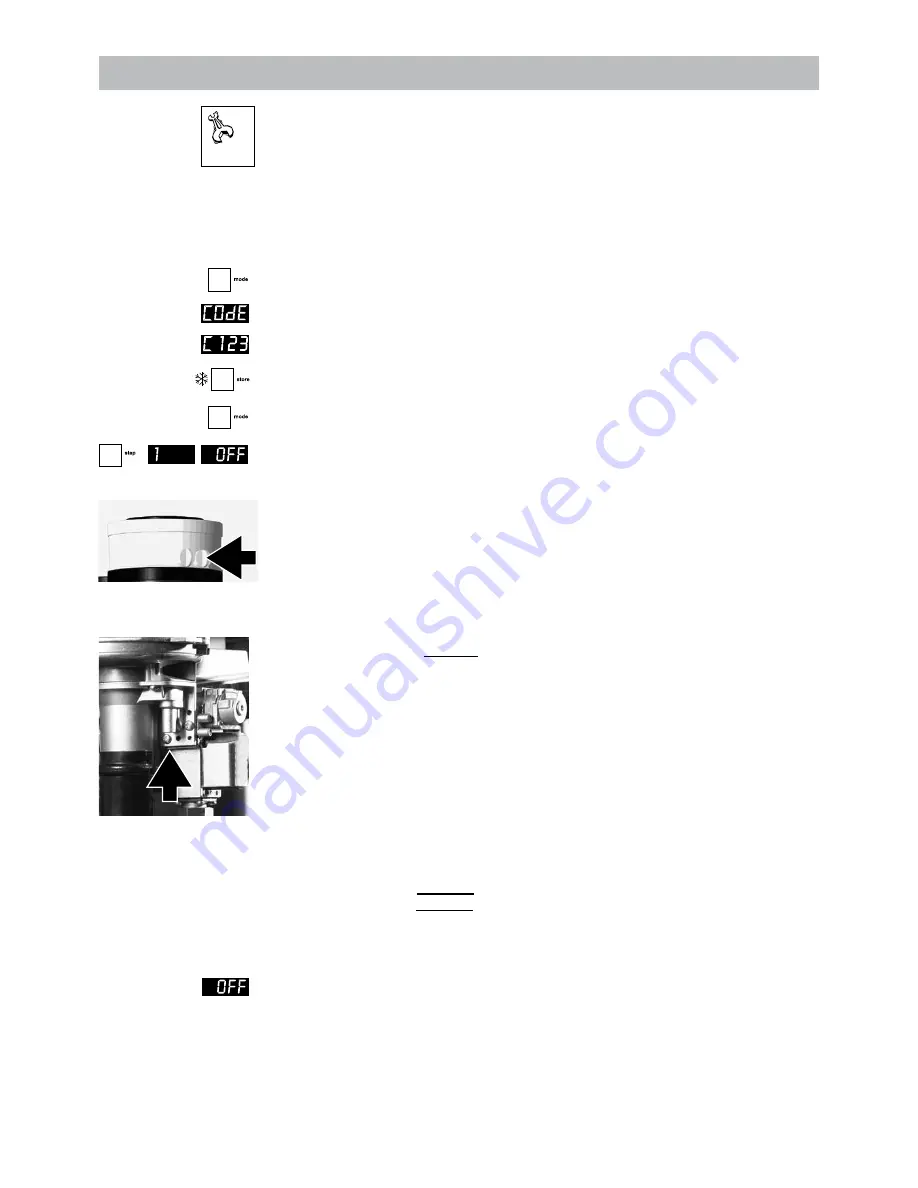

- Place the lance of the O

2

meter into the check point (see fig. 12.2.a);

- Press the + key until the maximum value (in kW) is achieved;

The boiler will burn on full load (value on display in kW)

Natural

gas

Propane

-

O

2

percentage at full load = 4,7% (-1,2%, +0,8%) 5,1% (-1,2%, +0,7%)

CO

2

percentage at full load

= 9,0% (-0,4%, +0,6%) 10,3% (-0.4%, +0.8%)

- Let the O

2

meter do its measuring procedure.

- Adjust, if necessary, the adjustment screw to correct the O

2

value

(see fig. 12.2.b).

Finally, the O

2

percentage at low load must be checked:

- Press on the - button until the minimum value has been reached.

The boiler will be burning at low capacity.

- Leave measuring O

2

to the measuring equipment and check if the measured O

2

percentage on low load is between following values:

Natural

gas

Propane

- O

2

percentage at low load

between 5,0% and 7,0%

5,1% and 7,0%

CO

2

percentage at low load

between 7,7% and 8,8%

9,1% and 10,3%

Contact A.O. Smith when the measured values is outside this range.

Ending the O

2

measuring procedure:

- Press the - key until OFF is shown (keep key pressed).

With this the procedure has ended..

- Replace the black cover on the gas valve and fix it with the screw.

adjustment screw CO

2

/O

2

figure 12.2.b

Measuring point figure 12.2.a