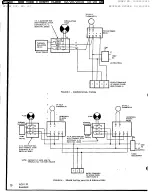

24VOLT

I

'2

'

2

'

2

2

2

'

2

2

2

0

5

5

5

5

5

6

I

1

I

0

LI

AC

I

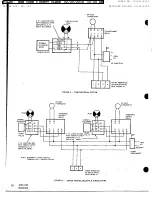

THERMAL

4 2 4 JUNCTION

BOX

WITHTERMINAL

STRIP

IOPTIONAU

A. 0,

(SEE

FIGURE

5

5

5

5

5

5

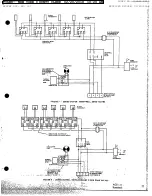

W EWERMOSTATS

4 8

4 8

4 -

S

4 .

4 6

4 6

4 8

4 5

4 8

4 5

4 5

4 5

3

1

3

1

3

1

3

3

1

3

40VATRANSFORMER

TOHANDLE

UPTO

.

8 ZONEVALVES

ZONE

VALVES

(w-RTYPE

1311.

MODEL

AA44E4

ORHIGHER

THAN41

T

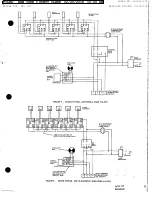

T

w.a

809-A

1

2

L

L

RELAY

CIRCUl.ATING

•)

o

0

u

PUMP

120V

YELLOW

L2

..

BLACK

INEUTHAL)

NCER

REO

WHITE

(PUMP

OEt.AY)

M H

.

NO. 9920)

ENTRY

TERMINALS

PT4TA.=r

4)

FIGuRE 9 - ZoNED SYSTEM - WHITE-RODGER5 3 WIRE ZONE YALVES

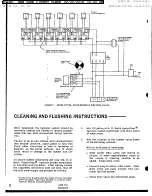

CLEANING

AND

FLUSHING

INSTRUCTIONS

When

completed,

the

hydronic

system

should

be

1.

Mix

1/2

gallon

of A.

O.

Smith

blydro-Prep

®

internally

cleaned

and

flushed

to

remove

contami-

hydronic

system

conditioner

with

three

quarts

nants

that

may

have

accumulated

during

installa-

of

warm

water.

tlon.

!

2.

Add

the

solution

to

the

system

using

either

Failure

to

do

so

can

produce

acid

concentrations

of

the

following

methods:

that

become

corrosive,

cause

gases

to

form

that

block

water

circulation

or

lead

to

formation

of

With

an

acid

pump

or

hand

pump

deposits

on

the

boiler

surfaces,

any

of

which

could

result

in

damage

to

the

system

and

cir-

a

Open

boiler

drain

valve

and

remove

an

culator.

amount

of

water

approximately

equal

to

the

volume

of

cleaning

solution

to

be

To

assure

system

cleanliness

and

long

life,

A.

O.

added.

Close

drain

valve.

Smith

*Hydro-Prep®

hydronic

system

conditioner

is

furnished

with

the

boiler.

After

making

'certain

•

Connect

pump

to

boiler

drain

valve,

Open

the

completed

installation

does

not

leak,

shut

off

drain

valve

and

pump

mixture

from

con-

the

cold

water

supply

and

proceed

as

follows:

tainer

into

the

system.

*AVAILA BLE IN QUARTS (PART NO. 97091) OR HALF GALLONS

•

Close

drain

valve

and

disconnect

pump.

(PART NO. 97092) FROM YOUR NEAREST A. O. SMITH CORP.

PRODUCT SERVICE DIVISION BRANCH.

12

AOS

112

Roenbeck

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018