I

SA

PA

:I

ERST

SWITCH

MANUAL

Through

pressure

relief

valve

opening

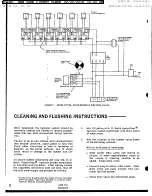

4.

Operate

the

system

for

a minimum

of

1 hour

(to

a maximum

of

24

hours).

As

noted

above,

•

Close

system

inlet

and

outlet

valves

at

the

system

pressure

and

temperature

must

be

boiler.

such

that

the

water

does

not

boll.

e

Relieve

pressure

flam

boiler

and

remove

pressure

relief

valve

from

air

purger.

5.

SYSTEM

MUST

NOW

BE

DRAINED

AND

FLUSHED.

•

Remove

an

amount

of

water

from

the

sys-

tem

approximately

equal

to

the

volume

of

^

.

Close

the

manual

gas

shutoff

valve

to

cleaning

solution

tp

be

added.

turn

off

the

burner.

This

will

allow

the

circulator

to

continue

operating

during

.

Add

the

cleaning

solution

to

the

system

the

flushing

procedure.

through

the

relief

valve

opening.

Replace

relief

valve.

.

Open'

the

cold

water

supply

to

the

sys-

tem.

.

Open

system

inlet

and

outlet

valves

at

boiler.

*

Connect

a

hose

to

the

boiler

drain

valve,

.

allow

cleaning

solution

to

flow

to

drairt.

3.

Pressurize

the

system.

If

necessary

, open

the

cold

water

supply

alve

and

add

pressure

.

All

cleaner

should

be

removed

after

15

to

to

the

system

so

that

the

water

does

not

boil

20

minutes

of flushing.

during

the

cleaning

process.

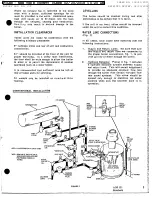

OPERATING

INSTRUCTIONS

LIGHTING

INSTRUCTIONS

6

b"

I

sura

120V. SOHz

CAUTION:

Make

sure

heater

is

filled

with

water

TONexreANE

before

lighting

pilot.

The

main

(man-

J'2SED

•

PUMP

ual)

gas

shutoff

valve

and

pilot

ad-

___ay

Eu.OW

____

justing

valve,

located

near

main

an

__....__

_____

burner,

should

be

closed

for

at

least

RM

WH E

TON

U EPO

Lt

5

minutes.

SYSTEM

OPERATING

CONTROL

Do

not

attempt

to

light

pilot

if gas

odor

is

present.

Light

the

unit

in

accordance

with

the

instructions

on

the

Lighting

and

Operat|ng

plate

fastened

to

cE

the

boiler.

.

,

NO

SAFETY I

.TRANSFORMER

TAANSPORMER

(24V)

P1LO

TO

Et1

I

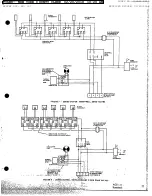

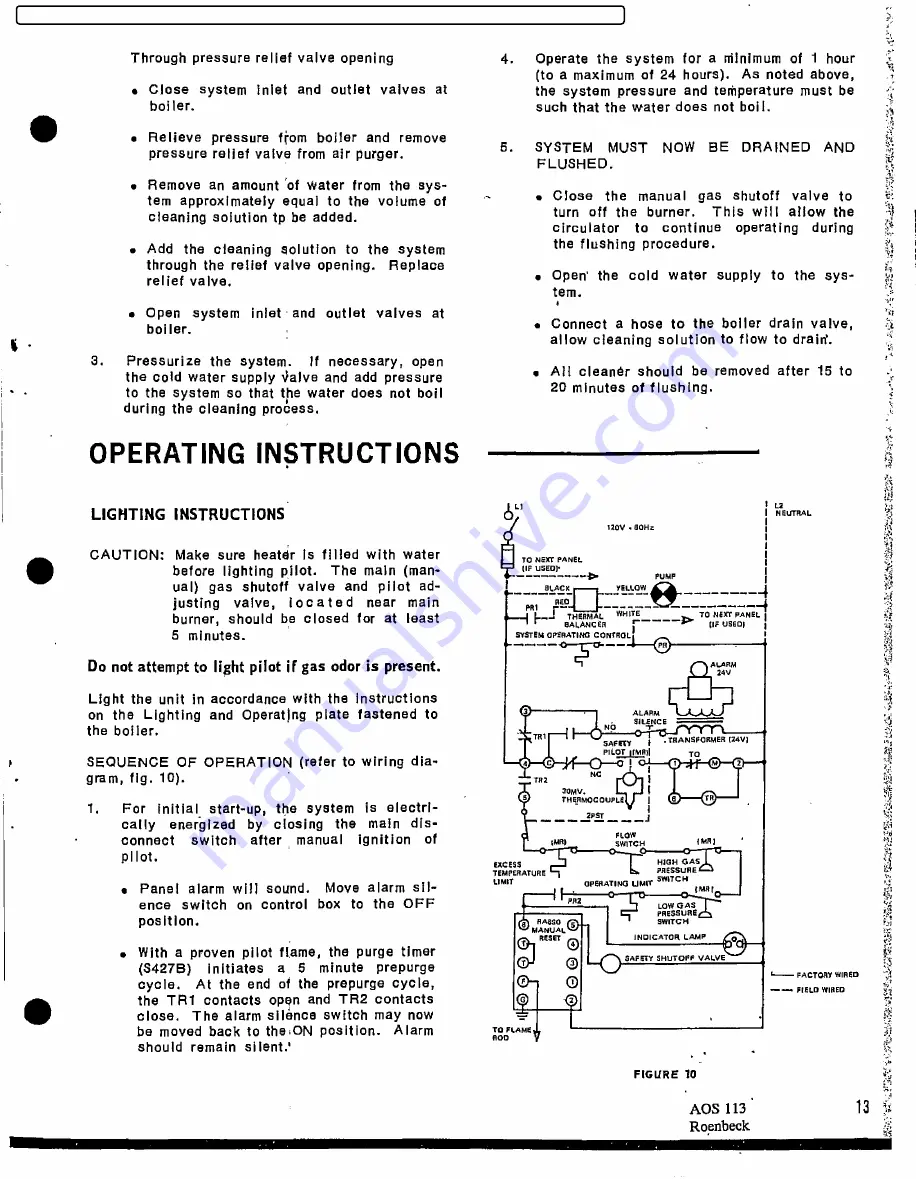

SEQUENCE

OF

OPERATION

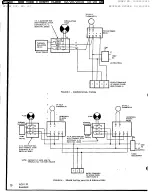

(refer

to

wiring

dia-

4

c

I

I

M

2

.

gram,

fig.

10).

TR2

I

30MV.

I

$

THERMOCOUPLE]

g

TR

1.

For

initial

start-up,

the

system

is

electri-

cally

energized

by

closing

the

main

dis-

connect

switch

after

manual

ignition

of

imm

cH

(MR

pilot.

EXCESS

HIGHGAS

TEMPERATURE

PRESSURE

e

Panel

alarm

will

sound.

Move

alarm

sil-

*

.

°""4'NG

IJMIT

IMAI

ence

switch

on

control

box

to

the

OFF

PR2

LOW

GAS

•

PRESSURE

position.

RA6SO

SWITCH

~

S

Q4

INDICATOR

LAMP

O

.

With

a proven

pilot

flame,

the

purge

timer

SAFETY

SHUTOFF

VALVE

(3427B)

initiates

a

5

minute

prepurge

L---- FACTORY

WIRED

cycle.

At

the

end

of

the

prepurge

cycle,

Q

--

FIELD

WillED

the

TR1

contacts

open

and

TR2

contacts

2

y

close.

The

alarm

silence

switch

may

now

.--

be

moved

back

to

theiON

position.

Alarm

TORAME

should

remain

silent.'

FlGURE

10

AOS

113

13

9

Roenbeck

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018