I

I

man.'

~

~

~ L

m

& I' l(5

4

I

~ ~I

gory

1

I

I

I

IP

»i

8I

I

~

I.~ ~

+

~ ~I

)V

ii

3600

X

H

=

Btuh

VALVE

ADJUSTMENTS

T

T

=

Time

la

seconds

to

burn

one

cubic

foot

Hydronic

Balancer

(By-Pass

Valve)

H

=

tu's

per

cubic

foot

of gas.

9

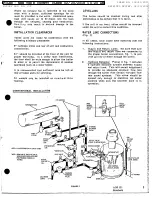

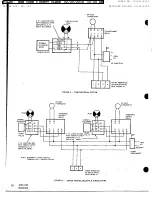

The

hydronic

balancer

valve

shown

In

fig.

1,

is

to

be

Installed

in

a connection

between

the

boiler

EXAMPLE:

(Using

HW-200

boiler)

outlet

and

the

pump

Inlet.

Certain

low

flow

zone

conditions

will

require

.balancing

to

provide

addi-

T

=

18.9

seconds

tional

flow

rate

through

the

boiler.

H

=

1050

Btu

Btuh

=

?

Initial

start-up

of

the

zone

with

lowest

flow

rate

may

require

partial

opening

of

this

valve

to

ata-

Gas

Flow

through.met

r:

ballze

boiler

operation

of

design

water

tempera-

a

ture.

No

further

adjustment

of

the

valve

will

be

8600

required.

X

1050

=

200

000

Btuh

p

18.9

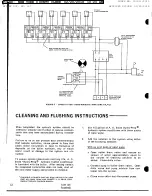

PRECAI.ITIONS

NOTE:

Under

no

circumstances

should

the

b

•

gas

Input

exceed

the

input

shown

on

If the

unit

la

exposed

to

the

following,

do

not

op-

the

boiler

rating

plate.

Overfiring

crate

boiler

until

corrective

steps

have

been

made

-

·

could

result

in

damage

or

sooting

of

by

a qualified

service

man:

the

heater.

1.

Flooding

to

level

of

burner

or

controls

or

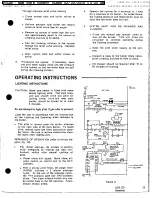

THERMOSTAT

CONTROL

SETTING

higher.

The.

thermostat

Is

a safety

device

wired

In

serles

2.

Exposure

to external

fire.

with

the

main

gas

valve.

Set

the

thermostat

con-

trol,

fig.

11,

to

approximately

100F

above

the

de-

8.

If damaged.

signed

system

temperature,

If

the

boiler

outlet

9

water

temperature

should

exceed

the

thermostat

4.

Firing

without

water.

setting,

the

main

gas

valve

will

close

but

the

circulator

will

continue

to

operate.

Maximum

ad-

5.

Scoting.

Justable

setting

Is

2400F

cut-out

with

a 50F

to

45°F

adjustable

differential.

d IW.I. w -.g

FIGURE 11

•

.

.

-AOS

115

15

"

Roenbeek

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018