t

'6

'. i

c

term

term

I

r

l.cl

I

cr)i

.

irxt

.,t

t

Ic;S

Ic,",

:-'-I

it

i+

.'c:-7

..

i

vc>1

~

c

lg

jxc-',

Vc=',

't

FOR

YOUR

SAFETY

aaaitb

Ieglitb

If you

smelt

gas:

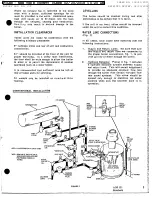

MODELS

1.

Open

windows

HW-160

RESIDENTIAL

TYPE

.

2.

Don't

touch

electrical

switches

HW-200

•

HYDRONIC

BOlLER

3.

Stinguish

any

open

flame

HW-225

4.

Immediately

call

your

gas

supplier.

with

FIA

LIMITED

WARRANTY

A. O. Smith Corporation, the warrantor, extends the following LIMITED WARRANTY to the awner of this hydronic boiler:

',I

1.

if within TEN years after initial Jnstallation of this bailer, a heat exchanger, coil or gas burner shall prove upon examination by the warrantor

to be defective

in material ar workmanship, the warrantor, of his aption will exchange or repair such port ar portion.

This term is reduced to

FlVE years if this boiler Is used for water heating purposes other than hydronic space heating.

a.

This warranty is extended to the awner for all ether parts ar partian during the FIRST year following initial

installation

of this boiler.

"tj

b.

The warranty on the repair or replacement of the part or portico will be limited to the unexpired

term^

of the original warranty.

2.

CONDITIONS and EXCEPTJDNS

.....

r,';

This warranty shall apply only when the boiler is Installed in accordance with local plumbing and building codes, ardinances and regulations, ~

the printed iristructlans

provided with it and acad industry practices.

in addition, a pressure relief valve, certified by the American Society a

Mechanical Engineers must have been installed and fresh water used far Filling and make-up purposes,

c,

a.

This warranty shall apply anly·

only

only when the boiler is used:

(1)

at temperatures not exceeding the maximum setting af its aperative and/ar high limit central;

(2)

at water pressure not exceeding the working pressure shown on the boiler;

I I,

(3)

when filled

with boiler water,

free to circulate

at all times and with the heat exchanger and call free of damaging scale

deposits

(4)

in a non-carrasive and ndn-contaminated atmosphere;

(5)

in the United States, Its territories

ar passesions.

(6)

with an intermittent circulating action and with the pump and burner operating together.

b.

Any accident to the boiler, ony misuse, abuse (including

freezing) ar afteration

of it, any operation of it In a modified form, ar any attempt

to repair leaks In the coil(s) or heat exchanger(s) will void this warranty.

ca

3.

SERVICE and REPAlR EXPENSE

Under this limited warranty the warrantar will provide anly a replacement part. The awner is responsible for oil ether costs,

Such costs may

Il.>cr

include but ore not limited to

",'6

a.

Lobar charges for service, removal, repair, ar reinstallatian

af the component part;

ir;

b.

Shipping, delivery,

handling, arid administrative

charges far forwarding the replacement part from the nearest distributor

and returning the

•

claimed defective

part to such distributar;

c.~

All cast necessary ar incidental far any materials and/or permits required far installerian

of the replacement.

4.

LIMITATION

ON IMPLIED WARRANTIES

Irnplled warranties, Including any wo;rranty of merchantability

imposed an the sale af this boiler under state law are limited to ane (1) year dur-

4.'

>lIt

ation for the heater or any af its parts. Same states do not allow limitations

on how long an implied warranty lasts, sa the above limitation may

i5

lip

not apply to you,

'.j

5.

CLAIM PROCEDURE

I+

Any claim under this warranty should be initiated

with the dealer wha sold the bailer, or with any ether dealer handling the warrantor's products.

hg

IF this is not practicable, the awner lhould

should contact:

U. 5. Customers except California

California

Customers ONLY

Canadian Customers

>Icy

A.~ O. Smith Carpararian

A. 0 Smith Corporattan

A. 0.5mith

Corporatiari

P. O. Box 28

.

33375 Central Avenue

P. O. Box 310 - 768 Erie Street

[

Konkakee, filinois

60901

Unlan City, California

94587

StratFard, Ontarlo

N5A 6T3

Telephone:

(815)

933-8241

Telephone:

(415) 489-4374

Telephone:

(519) 271-5800

a.~

The warrantor will

only bonar replacement with identical

ar similar

parts thereaf which are manufactured or distributed

by the warrontor.

b.

Dealer replacements are nada subject

bject to in-warranty validation by warrantor.

8 „

ii

6,

DISCLAIMERS

f.

I

c

K

NO OTHER EXPRESS WARRANTY

AS

)AS BEEN OR WJLL BE MADE IN BEHALF

OF THE WARRANTOR WITH RESPECT TO THE BolLER

OR

THE INSTALLATION,

OPERATION, REPAIR OR REPLACEMENT

OF THE BolLER. ~ THE WARRANTOR SHALL NOT BE RESPONSIBLE FOR

)~i

WATER DAMAGE, LOSS OF USE OF THE UNIT, INCONVENIENCE,

LO55 OR DAMAGE TO PERSONAL PROPERTY,

OR OTHER CONSEQUEN-

TJAL DAMAGE.

THE WARRANTOR SHALL NOT BE LIABLE

BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR DAMAGE TO ANY PER.

SONS OR PROPERTY, WHETHER DIRECT OR INDIRECT, AND WHETHER ARISING IN CONTRACT OR TORT.

a.

Some states da not allow the exclusian ar Ifmitation

of the Incidental

ar consequential damage, so the above limitation

or exclusion

may not

iFI

apply to you.

'15

b.

This warranty gives you specific legal rights, ond you may also have other rights which vary from state to state.

I

Fill

In the fal[awing far your own reference. Keep it. Registration is not a candition of warranty.

The model and serial number ore found on the boiler's

rating plate.

V

I>5

il

•

Owner

.

Installation

Address

~

~ m

m ~

~

math

lc*c

City and 5tate

.

rom=onarsonr

Date Installed

Madel No.

Serial No.

CONSUMER PRODUCTSDIVISION

KANKAKEE, ILLlNOIS

j'$

Dealer's

Name

Phane No.

AÑD

pir

STRATFORD, ONTARIO. CANADA

Dealer's Address

PART No. 76035

?v.

PRINTED IN U.S.A.

3395

177

FILL JN WARRANTY AND KEEP FOR FUTURE REFERENCE

AOS

117

REVISION 2

Roenbeck

Roenbeek

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018