I

I

.

8.

Water

Supply

Line

and

Operatinn

Preasures.

If

the

boiler

la

connected

to

heating

colla

These

boilers

can

be

used

ONLY

In

a forced

exposed

to

refrigerated

air,

the

boiler

piping

hot

water

heating

system.

The

water

supply

'

system

must

be

equipped

with

flow

valves

or

line

must

Include

a pressure

reducing

valve

other

automatic

means

to

prevent

gravity

to

establish

propel

system

operating

prea-

circulation

through

the

boiler

during

the

sure.

Modern,

fast.

heating

hydronic

boilers

cooling

cycle.

function

best

with

a cold

fill

pressure

of

12

7.

Circulating

Pump.

Constant

circulating

pump

to

18

pal.

If

system

water

volume

and

op-

operation

of

the

boiler

voids

the

warranty.

temperature

can

be expected

to create

Constant

water

flow

through

the

unit

will

an

expanded

pressure

up

to

or

more

than

80

'wash'

away

the

copper's

natural

protective

pal,

these

boilers

can

be

ordered

with

a 65

coating.

Thla

la

called

velocity

erosion.

pressure

relief.

This

will

be

a substitute

This

erosion

la

not

as

great

a problem

when

for

the

30

pal

valve

normally

shipped

with

Intermittent

circulating

operation

Is

used

per

the

boiler.

Relief

valve

relieving

pressure

the

recommended

Installation

procedure.

Con-

should

not

exceed

the

operating

pressure

of

ajant

circulating

of

water

through

the

build-

any

system

component.

The

A.

.O.

Smith

ing's

system

main

is

permissible

as

Iong

as

boilers

are

rated

for

180

pal

maximum

work-

the

water

does

not

constantly

flow

through

ing

pressure.

the

boiler.

Systems

with

large

water

volume

and

sya-

Although

each

circulator

la

oiled

and

op-

tems

requiring

predsure

purging

abould

be

crated

by

the

manufacturer,

IT

MUST

BE

Installed

with

by

ass

piping

around

the

OILED

AGAIN

BEFORE

OPEFIATED.

Oil

pressure

reducing

valve.

the

three

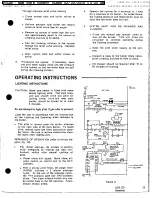

oil

cups

(2

on

the

motor,

1 on

the

pump)

as

instructed

on

the

oil

tube

supplied

4.

Vent

Valves.

It

la.recommended

that

auto-

with

the

unit,

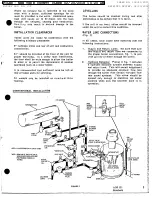

fig.

S.

matic,

loose

key

or

acrowdriver

type

vent

valves

be

Installed

at

each

convector

6

QL

• radiator

and

other

high

points

In

the

dis-

tribution

system.

If

automatic

vents

are

used,

pressure

at

11 times

must

be

high

enough

to

prevent

air

entry

through

these

devices.

.

-

-F

...

-.

,

. _ I

5.

Manlfold

Headers.

·For

multi-loop

systems

using

one

circulator;

manifold

headers

must

be

Installed

in

the

pupply

and

return

lines.

-

For

2

or

8 circuits

using

S/4"

O.D.

copper

and

2, 3 or 4 circuits

using

1/2"

O.D.

.

tubing,the

manifold

should

be

at

least

1

1/2"

1/2

In

diameter.

The

circuits

should

_be

be

spaced

• -

on

the

header

at

a

minimum

of

three

Inches

center

to

center.

Ins.tall

a balancing

cock

In

-- -

-

•

-

each

return

line.

6.

Cooling

Piping.

.

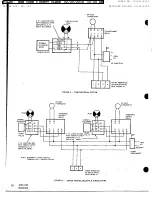

Flow

control

valves,

manual

or

motorized,

must

be

Installed

to

control

PieuRit

s

othino

CIRCULAToR

water

flow

through

deplred

unit,

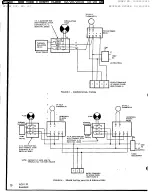

fig.

2.

Thereafter,

during

the

heating

season,

lub-

Water

temperature

In the

heating

system

must

ricate

the

three

oil

cups

at

least

once

every

be

reduced

to

less

than

100

degrees

F before

4

months.

Combination

heating-cooling

sys-

cooling

system

la

started,

or

damage

to

the

toma

should

be

lubricated

every

four

months

chiller

unit

may

occur.

year

around.

RETUM

suPPLY

BOILER

CHILLER

-

COOLING

CIRCULATOR

leURE 2

RECOMMENDEDPIP1NG

DIAGRAM

-

6

AOS122

Roanbecir.

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018