2.

With

,excess

excess

temperature

limit,

flow

switch,

main

burners.

Manual

resetting

of

this

con-

operating

limit,

system

operating

control,

trol

is

required.

high

gas

pressure

and

low

gas

pressure

switches

closed,

the

RA

890

relay

performs

9.

Low

water

or

no flow

condition:

its

electronic

check.

Its

toad

relays

then

pull

in

to

energize

terminal

5

of

the

relay,

.

The

flow

switch

contacts

will

open,

shut-

powering

the

gas

safety

shutoff

valve.

Main

ting

off

main

burner.

Boiler

will

not

fire

burners

ignite.

until

normal

flow

c ond

itions

are

re-

established.

3.

System

operating

control

is

satisfied.

.

Safety

shutoff

valve

is de-energized.

10.

If

the

red

running

light

on

the

control

box

fails,

the

following

safety

devices

should

.

Main

burner

shuts

off.

be checked:

.

Pilot

continues

to

burn

on

stand-by

.

O'perating

Limit

operation.

.

Low

Gas

Pressure

Switch

4.

If

flame

failure

occurs:

.

High

Gas

Pressure

Switch

.

.

Absence

of

flame

is

sensed

within

2

- 4

seconds.

.

Flow

Switch

.

Terminal

5

of

RA

890

relay

is

de-ener-

.

Excess

Temp.

Limit

Control

gized

and

main

burners

shut

off.

5.

If flame

cannot

be proven

within

15 seconds:

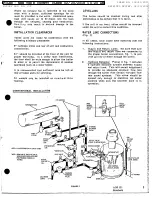

AIR

SHUTTER

ADJUSTMENT

.

The

RA

890

relay

will

lock

out

on

safety'

To

obtain

ideal

main

burner

operating

conditions,

closing

the

normally

open

(N.O.)

alarm

the

gas

and

air

must

be

properly

proportioned.

The

contacts

onrelay

and

activate

alarm.

proper

air-gas

mixture

may

be

obtained

by

rotating

the

air

shutter

on face

of burner.

.

Pilot

safety

switch

contacts

open

and

pilot

gas

supply

shuts

off

in

approximately

NOTE:

Spreader

type

burners

have

an

orange

90 seconds.

quality

In

the

flame

when

used

on

L.P.

gas.

This

is

a normal

and

approved

char-

.

After

cause

of

failure

has

been

corrected,

acteristic.

the

safety

switch

of

the

RA

890

relay

must

be

manually

reset

and

pilot

relighted

1.

Operate

the

system.

before

main

burner

will

re-lgnite.

2.

Loosen

the

locknut

and

open

the

air

shutter

6.

Low

gas

pressure:

wide.

.

If

regulator

outlet

pressure

to

the

control

3.

Gratiually

close

the

shutter

until

yellow

tips

string

drops

to

less

than

2.0"

W.C.

(Nat-

appear

in

the

burner

flame.

Slowly

re-open

ural

gas)

or

9.0"

W.C.

(Propane

gas),

the

the

shutter

until

the

flame

tips

are

blue.

Do

low

gas

pressure

switch

contacts

will

not

open

shutter

any

further

than

necessary

open,

shutting

off

the

main

burners.

Man"

as

flame

will

become

noisy

and

lift

from

the

ual

resetting

of

the

pressure

switch

is

burner.

required.

7.

High

gas

pressure:

CHECKING

AND

ADJUSTING

THE

INPUT

If

gas

supply

pressure

to

the

main

burner

orifices

exceeds

4,0"

W.C.

(Natural

gas)

or

1.

Attach

a

pressure

gauge

or

a

manometer

to

12.0"

(Propane

gas),

the

high

gas

pressure

the

gauge

port

and

refer

to

TABLE

2

for

contacts

will

open,

shutting

off

the

main

correct'manifold

pressure.

burners.

Manual

resetting

of

the

pressure

switch

is

required.

NOTE:

The

gas

meter

should

be

clocked

be-

fore

system

water

temperature

ex-

8.

Excessive

water

temperature:

ceeds

1500F.

If

boiler

water

temperature

exceeds

setting

2.

Use

this

formula

to

"crock"

the

meter.

Be

of

excess

temperature

limit

control,

the

con-

sure

that

other

gas

consuming

appliances

tacts

in

the

control

open,

shutting

off

the

are

not

ON

during

this

interval.

AOS

130

14

Raenbeck

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018