of

gas.

f

'

'A.

';.

'4

«",r'-

s+)~

«„i'Jl,

'-.

','

*

„;

«r

r

t

3600

X

H

=

Btuh

VALVE

ADJUSTMENTS

T

T

=

Time

is

seconds

to

burn

one

cubic

foot

Hydronic

Balancer

(By-Pass

Valve)

e

H

=

Btu

s

er cubic

foot

of gas.

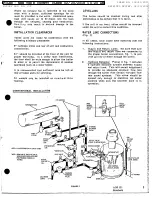

The

hydronic

balancer

valve

shown

in

fig.

1,

is

to

be

installed

in

a connection

between

the

boiler

EXAMPLE:

(Using

HW-200

boiler)

outlet

and

the

pump

inlet.

Certain

low

flow

zone

conditions

will

require

balancing

to

provide

addi-

T

=

19

seconds

tional

flow

rate

through

the

boiler.

H

=

1050

Btu

Btuh

=

?

Initial

start-up

of

the

zone

with

lowest

flow

rate

may

require

partial

opening

of

this

valve

to

sta-

Gas

Flow

through

meter:

balize

boiler

operation

of

design

water

tempera-

ture.

No

further

adjustment

of

the

valve

will

be

3600

required.

X

1050

=

199,000

Btuh

l9

PRECAUTIONS

NOTE:

Under

no

circumstances

should

the

gas

input

exceed

the

Input

shown

on

If

the

unit

is

exposed

to

the

following,

do

not

op-

the

boiler

rating

plate.

Overfiring

crate

boiler

until

corrective

steps

have

been

made

could

result

in

damage

or

sooting

of

by

a qualified

service

man:

the

heater.

1.

Flooding

to

level

of

burner

or

controls

or

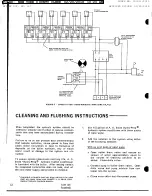

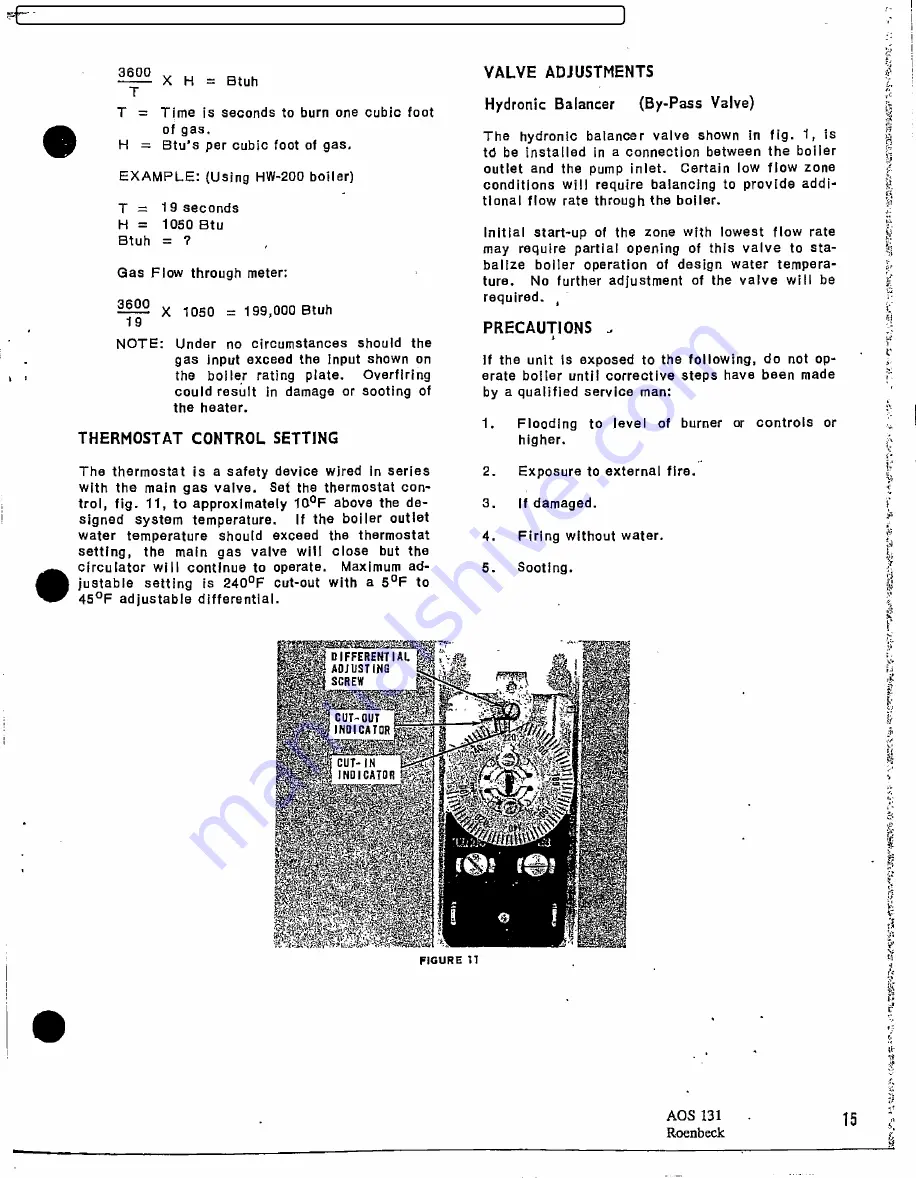

THERMOSTAT

CONTROL

SETTING

higher.

The

thermostat

is

a safety

device

wired

in

series

2.

Exposure

to external

fire.

with

the

main

gas

valve.

Set

the

thermostat

con-

.

trol,

fig.

11,

to

approximately

100F

above

the

de-

3.

If damaged.

signed

system

temperature.

If

the

boiler

outlet

water

temperature

should

exceed

the

thermostat

4.

Firing

without

water.

setting,

the

main

gas

valve

will

close

but

the

circulator

will

continue

to

operate.

Maximum

ad-

5.

Scoting.

justable

setting

is

240°F

cut-out

with

a 5°F

to

45°F

adjustable

differential.

«+>~ DIFFERIENTIAL ~up~.,'..~

~'

ADJUSTING

SCREW

CUT-0UT

INDICATOR

CUT-IN

INDICATOR

F]GURE D

AOS

131

.

15

Lg

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018