I

I,

GAS

CIRCULATOR

h

C

/

J

S"

Where

an

exhaust

fan

Is

Installed

in

the

same

LEVELLING

.

room

with

a

boiler,

suffialent

openings

for

air

must

be

provided

in

the

walls.

Undersized

open-

The

boiler

should

be

checked

during

and

after

ings

will

cause

air

to

be

drawn

into

the

room

installation

to

be certain

that

it

is

level.

through

the

chimney,

causing

poor

combustion.

Sooting

may

result

in

serious

damage

to

the

If

the

unit

is

not

level,

shims

should

be

inserted

boiler.

under

the

unit

to

correct

this

condition.

INSTALLATION

CLEARANCES

WATER

LINE

CONNECTIONS

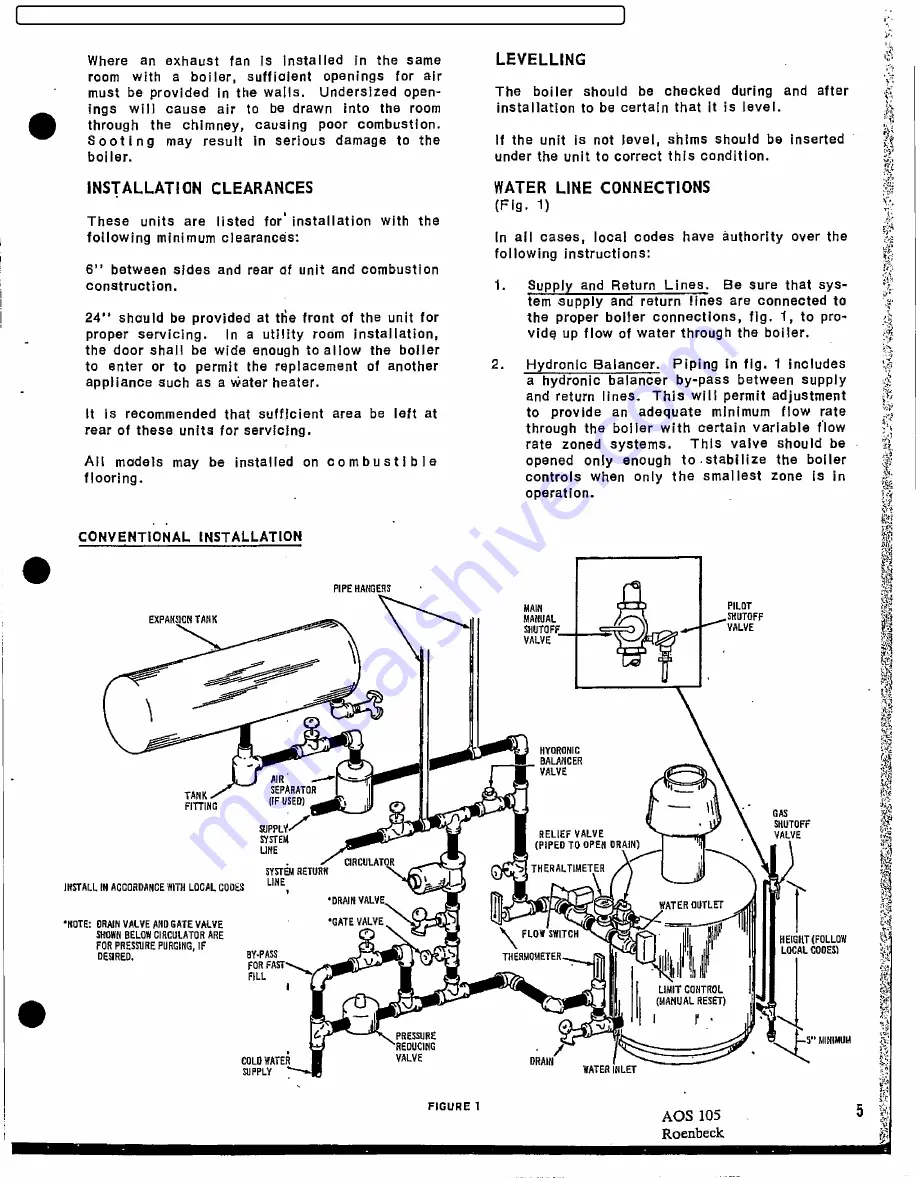

(Fig.

1)

These

units

are

listed

for'

for

installation

with

the

following

minimum

clearances:

In

all

cases,

local

codes

have

authority

over

the

following

instructions:

6"

between

sides

and

rear

of

unit

and

combustion

construction.

1.

Supply

and

Return

Lines.

Be

sure

that

sys-

tem

supply

and

return

lines

are

connected

to

24"

should

be

provided

at the

front

of

the

unit

for

the

proper

boiler

connections,

fig.

1,

to

pro-

proper

servicing.

In

a

utility

room

installation,

vide

up flow

of water

through

the

boiler.

the

door

shall

be

wide

enough

to allow

the

boiler

to

enter

or

to

permit

the

replacement

of

another

2.

Hydronic

Balancer.

Piping

in

fig.

1 includes

appliance

such

as

a water

heater,

a

hydronic

balancer

by-pass

between

supply

d

and

return

lines.

This

will

permit

adjustment

It

is

recommended

that

sufficient

area

be

left

at

to

provide

an

adequate

minimum

flow

rate

rear

of

these

units

for

servicing.

through

the

boiler

with

certain

variable

flow

rate

zoned

systems.

This

valve

should

be

S

All

models

may

be

installed

on

combustible

opened

only

enough

to.stabilize

the

boiler

flooring.

controls

when

only

the

smallest

zone

is

in

operation.

CONVENTIONAL

INSTALLATl0N

t

PIPEHANGERS

MAIN

PILOT

EXPANSICNTANK

MANUAL

SHVTOFF

SHOTOFF_,_

VALVE

VALVE

HYORONIC

BALANCER

AIR

--

VALVE

TANK

SEPARATOR

FITTING

[FFUSED)

,

SUPPLy

I

SKUTOFF

sygy

RELLEFVALVE

VALVE

LINE

(PIPEDTOOPENDRAIN)

SYSTEM

RETURN

)

THERALTIMETER

NSTALL

INACCORDANCE

WITHLOCALCODES

UNE

*DRAIM

VALVE

WER COTLEr

*NOTE:ORAIN

VALVEANDGATE

VALVE

*GATEVALVE

)if

SHOWN

BELOW

CIRCULATOR

ARE

FLOWSWITCH

ii

FORPRESSllRE

PURGING,

IF

!'

HEIGitT

(FOLLOW

DESIRED,

BY-PASS

.3

THERM0METER

LOCAL

CODES)

FORFAST

FILL

I

LIMITCONTROL

t

(MANUAL

RESET)

E

PRESSURE

-5" AllNIMUM

REDilClNG

.

COLD

WATEÑ

VALVE

DRAIN

SUPPLY

WATER

lNLET

FIGuRE 1

5

AOS

105

Roenbeck

P~

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018