17

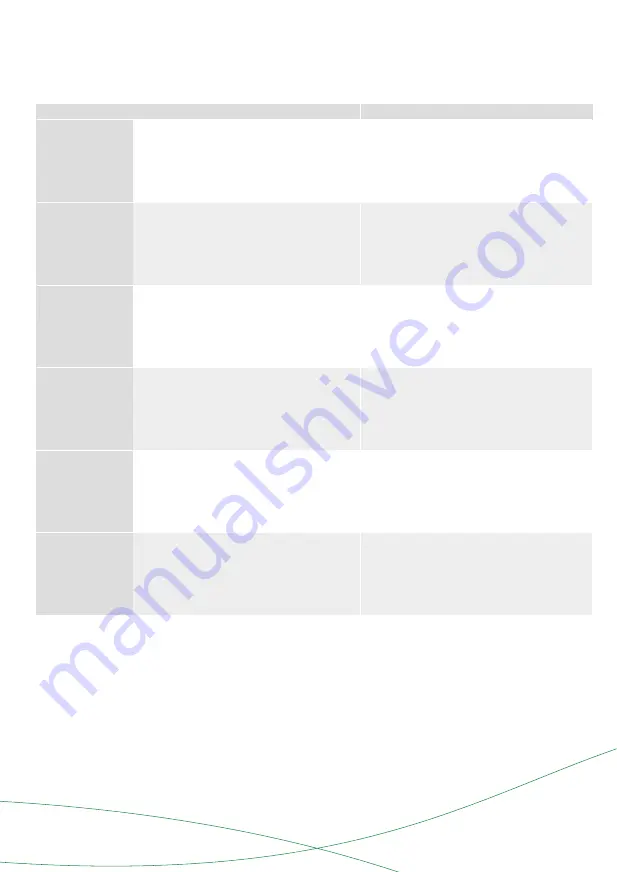

Troubleshooting Guide

FAILURE EXPERIENCED

REASON

RESOLUTION METHOD

•

The power source is not connected

•

Low inlet water pressure or no water

•

Low-pressure switch failure, cannot connect the power

source

•

High-pressure switch cannot be restored

•

Switch Mode Power Supply is burned out

•

High-pressure pump has lost pressure

•

Inlet water solenoid valve is faulty, no water can get in

(no pure water)

•

A pre-filter is blocked

•

Check valve is blocked (waste water, no pure water)

•

The RO Membrane is plugged

•

Check valve has lost pressure

•

High-pressure switch failure

•

System is exhibiting a loss of pressure

•

Pre-filter is plugged

•

RO membrane is plugged

•

Inlet solenoid valve failure

•

Check valve is plugged

•

Post-carbon filter is plugged

•

High pressure pump pressure is not enough

•

Storage tank doesn’t have enough pressure

•

Post-activated carbon filter is plugged

•

Inlet solenoid valve failed, cannot effectively

cut off the water supply

•

Check valve has lost pressure (small W.W. flow rate)

• Check the power source or the power source plug

• Check the inlet water pressure

• After connecting the inlet water, measure the

resistance, replace

• After letting off the pressure, measure the resistance,

replace

• Measure the output voltage, replace

•

Replace the pre-filter

•

Wash or replace the RO membrane

•

Replace the inlet solenoid valve

•

Replace the check valve

•

Replace the post-carbon filter

•

Measure the high pressure pump water pressure,

replace

•

Measure the water pump pressure, replace

•

Replace the solenoid valve

•

Observe the pure water and waste water,

replace the pre-filter

•

Replace the check valve

•

Clean or replace the RO membrane

•

Replace the check valve

•

Replace the high pressure switch

•

After checking the non return valve, check whether

there is water leakage in the pipelines

•

Inflate the storage bucket, empty tank pressure

should be between 0.05 and 0.07MPa

•

Replace the post-activated carbon filter

•

Observe the waste water, replace the inlet solenoid

valve

•

Observe the waste water, replace the check valve

The machine will not

start

The high pressure pump

is working properly,

but no water is being

produced

The storage tank is full

but no pure

water is flowing out

The machine is turned off

but waste water has not

stopped

After the machine is

filled with water, the

machine starts repeatedly

The pure water flow is

small or not flowing